CuInSe2-based thin film solar cell

A solar cell, cuinse2-ysy technology, applied in the field of solar cells, can solve problems such as insufficient utilization of incident light and limited contribution of device conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

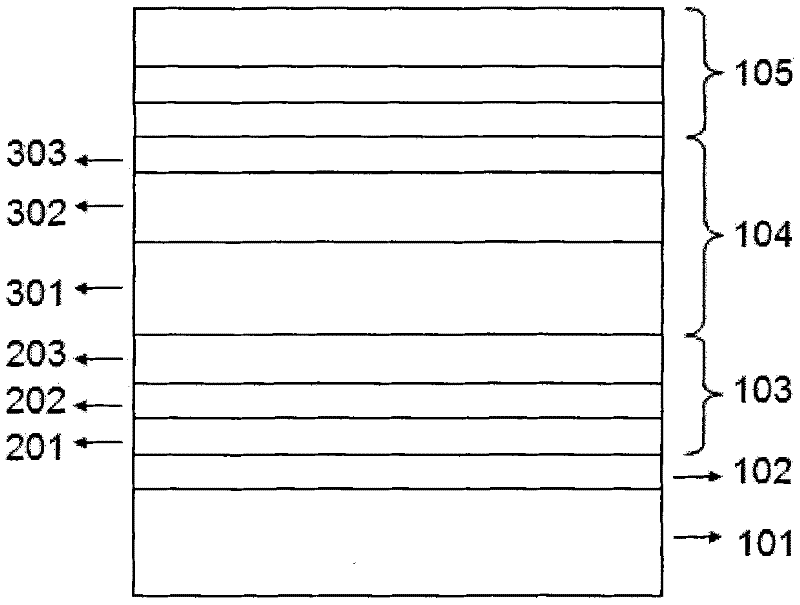

[0063] Such as figure 1 As shown, a CuInSe 2 The base thin-film solar cell is composed of a glass substrate 101 , a Mo thin-film electrode 102 , a reflective layer 103 , a photoelectric conversion layer 104 and a transparent conductive layer 105 in sequence.

[0064] The glass substrate 101 is made of soda-lime glass, and the Mo thin-film electrode 102 is deposited on the glass substrate 101 by magnetron sputtering. The thickness of the Mo thin-film electrode 102 is 1 μm, and the sheet resistance is 0.1-0.2Ω / □.

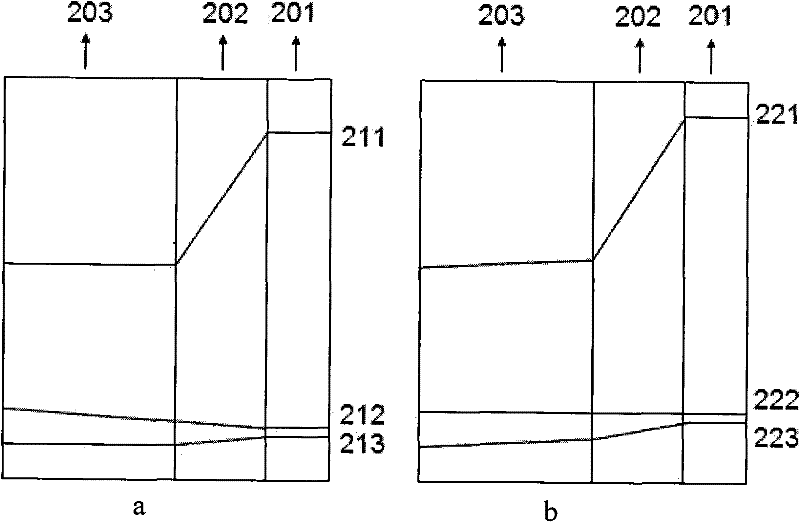

[0065] Such as figure 2 As shown, the reflective layer 103 is made of CuAlSe 2 / CuAl x Ga 1-x Se 2 / CuGaSe 2 The films are sequentially formed, among which, CuAlSe 2 The thickness of the film 201 is 10nm; CuAl x Ga 1-x Se 2 The thickness of the film 202 is 15nm; CuGaSe 2 Thin film 203 has a thickness of 25 nm.

[0066] In the reflective layer 103, CuAlSe 2 Thin film 201 is a p-type semiconductor thin film material, and its carrier concentration is 5×10 ...

Embodiment 2

[0089] Same as Example 1, except:

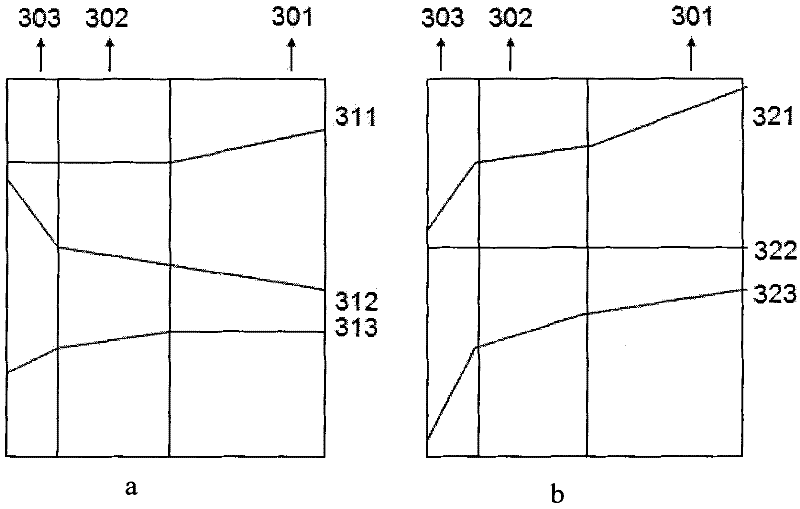

[0090] CuAlSe 2 The thickness of film 201 is 15nm, CuAl x Ga 1-x Se 2 The thickness of the thin film 202 is 20nm, CuGaSe 2 The thickness of the film 203 is 30nm; CuIn x Ga 1-x Se 2 Thickness of film 301 is 750nm; CuInSe 2-x S x The thickness of film 302 is 550nm; Cu 1-y Zn y InSe 2-x S x The thickness of the film 303 is 100nm; the thickness of the CdS film is 50nm, the thickness of the i-ZnO film is 60nm, and the thickness of the AZO film is 800nm.

[0091] CuInSe of this embodiment 2 The photoelectric conversion efficiency of the base thin film solar cell can reach more than 23% under standard irradiation conditions.

Embodiment 3

[0093] Same as Example 1, except:

[0094] CuAlSe 2 The thickness of the film 201 is 20nm, CuAl x Ga 1-x Se 2 The thickness of the film 202 is 50nm, CuGaSe 2 The thickness of the film 203 is 20nm; CuIn x Ga 1-x Se 2 Thickness of film 301 is 850nm; CuInSe 2-x S x The thickness of film 302 is 450nm; Cu 1-y Zn y InSe 2-x S x The thickness of the film 303 is 120nm; the thickness of the CdS film is 70nm, the thickness of the i-ZnO film is 70nm, and the thickness of the AZO film is 650nm.

[0095] CuInSe of this embodiment 2 The photoelectric conversion efficiency of the base thin film solar cell can reach more than 22% under standard irradiation conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com