A perc solar photovoltaic cell that can improve photoelectric conversion efficiency

A photoelectric conversion efficiency, photovoltaic cell technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of reduced battery fill factor, difficult electrode ohmic contact, and reduced carrier life, so as to achieve a smooth diffusion layer surface and improve Battery efficiency, improvement of further improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

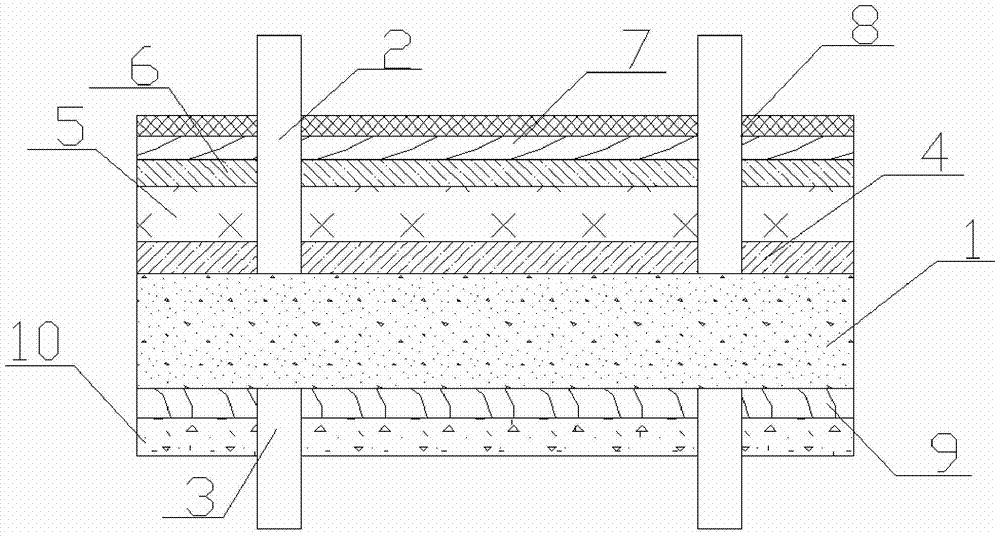

[0042] A PERC solar photovoltaic cell that can improve photoelectric conversion efficiency provided by this embodiment has a structure such as figure 1 As shown, it includes a silicon substrate 1 and a positive electrode 2 and a back electrode 3 directly sintered on the light-facing surface and the back surface of the silicon substrate 1, respectively. The light-facing surface of the silicon substrate 1 is provided with a silicon dioxide layer 4, thickness A first passivation layer 5 of 10-15nm, an anti-reflection layer 6, a conductive film 7 and a transparent glass 8 with a thickness of 100-200nm, and the back side of the silicon substrate 1 is provided with a second passivation layer with a thickness of 7-9nm Layer 9 and aluminum back field 10, wherein:

[0043] Both the first passivation layer 5 and the second passivation layer 9 are aluminum oxide films, and the anti-reflection film 6 has a three-layer structure, which includes the first silicon nitride film, the titanium ...

Embodiment 2

[0050] This embodiment provides the above-mentioned preparation method of the PERC solar photovoltaic cell that can improve the photoelectric conversion efficiency, which specifically includes the following steps:

[0051] (1) Manual detection is used to detect the silicon substrate sheet. The operator wears disposable gloves, twists the silicon substrate sheet into a fan shape, and observes one by one whether there are fragments, oil stains, unqualified dimensions and cracks, and rejects unqualified ones;

[0052] (2) Immerse the silicon substrate in a sodium hydroxide solution with a concentration of 1-2%, control the temperature at 80-85°C, immerse for 20-25min, and make texture on the silicon substrate, at 600-700°C , with liquid POCl 3 As a P source, phosphorus diffusion is performed on the substrate in a diffusion furnace;

[0053] Nitrogen protection is introduced when phosphorus diffuses, and oxygen is introduced at the same time. The nitrogen flow rate is 5-8L / min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com