Substrate inspecting jig, and electrode structure of connecting electrode unit in the jig

A technology of substrate inspection and connection of electrodes, applied in electronic circuit testing, components of electrical measuring instruments, measuring electricity, etc., can solve the problems of contact stability and low contact resistance value, and reduce the contact resistance value, The effect of stable and stable contact resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Hereinafter, the best mode for carrying out the present invention will be described.

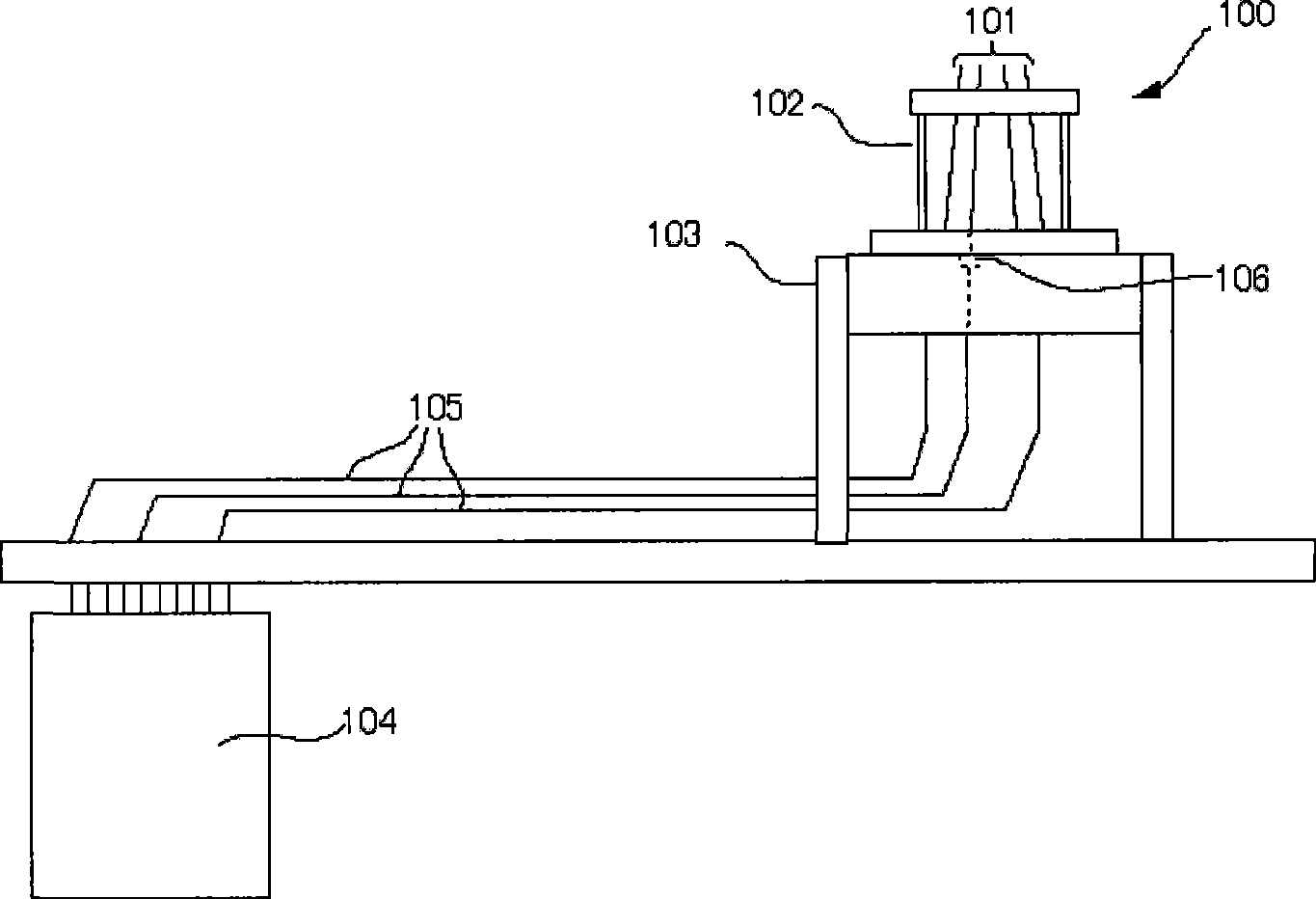

[0059] figure 1 A schematic configuration when using the substrate inspection jig of the present invention is shown. Should figure 1 In the figure, a plurality of stems 101, a support body 102 for fixing these stems 101 in a multi-needle shape, a connection electrode body 103 having a connection electrode portion that supports the support body 102 while contacting the stem 101 to realize conduction, and processing The inspection signal processing unit 104 of the detected electric signal and the electric wire 105 connecting the inspection probe 101 and the inspection signal processing unit 104 . The probe 101 is a terminal that contacts each inspection point of the wiring pattern formed on the substrate to be inspected. The connecting electrode body 103 performs pitch conversion between the probe 101 and the inspection signal processing unit 104 and electrically connects them.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com