Microbial preparation for processing refuse leachate and preparation

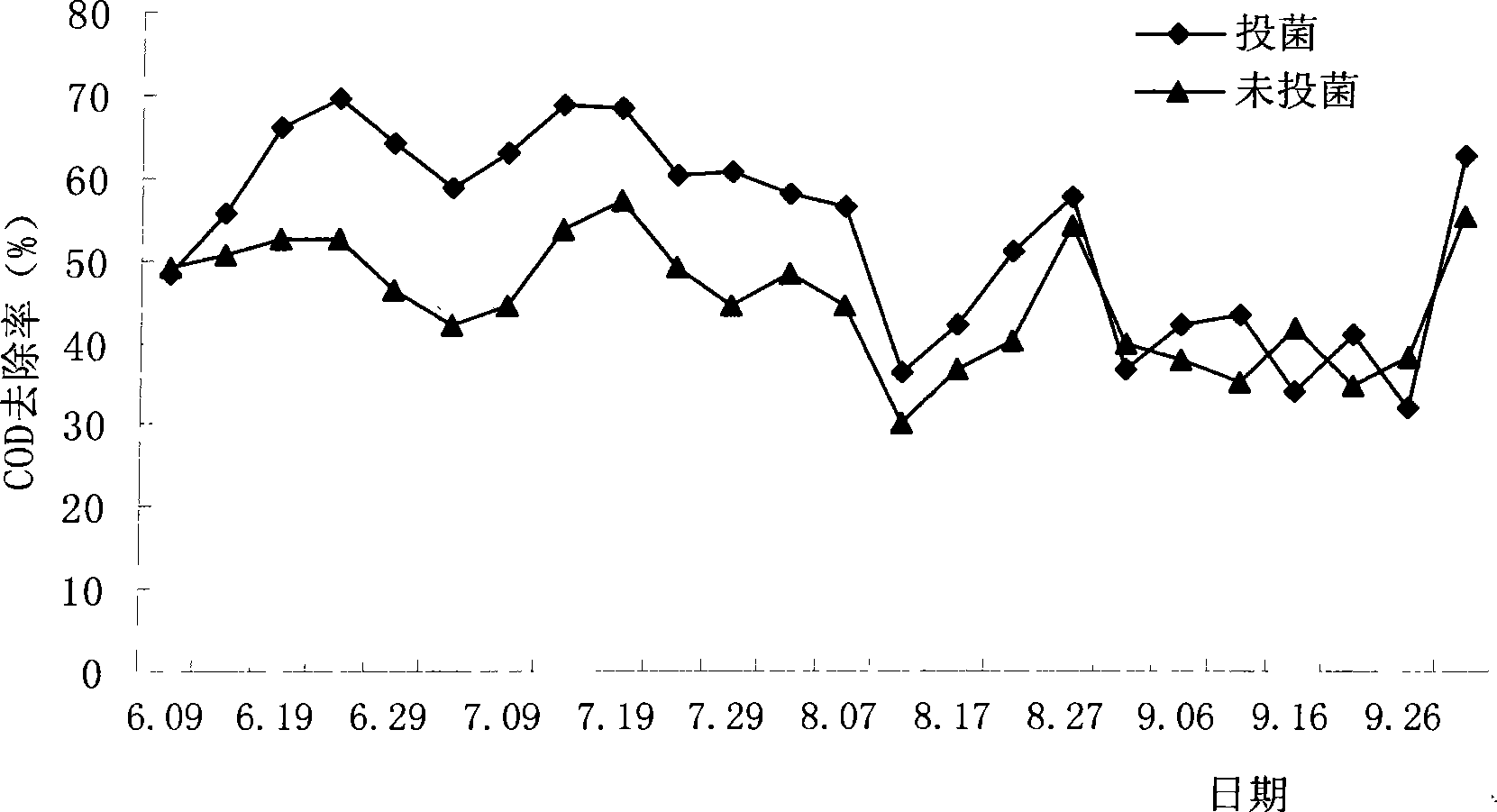

A technology for microbial preparations and landfill leachate, which is applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of long start-up time and unsatisfactory effects of biological treatment processes, and achieve enhanced system stability. Strong adaptability and improved removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of liquid medium I: Weigh 1 part of magnesium sulfate heptahydrate, 0.2 part of potassium chloride, 2.47 parts of sodium chloride, 0.3 part of sodium citrate, 1 part of yeast extract powder, 0.5 part of tryptone, and add water to 100 parts , adjust the pH to be 7.2 to make liquid medium I;

[0040] Preparation of liquid medium II: weigh 1.2 parts of magnesium sulfate heptahydrate, 0.2 parts of potassium chloride, 2.4 parts of sodium chloride, 0.3 parts of sodium citrate, 0.2 parts of ammonium chloride, 0.5 parts of yeast extract powder, 0.15 parts of pancreatic Peptone, 0.7 part of starch, 0.5 part of glucose, add water to 100 parts, adjust pH to 7.2 to prepare liquid medium II.

Embodiment 2

[0042] Preparation of liquid medium I: Weigh 1 part of magnesium sulfate heptahydrate, 0.2 part of potassium chloride, 2.47 parts of sodium chloride, 0.3 part of sodium citrate, 1 part of yeast extract powder, 0.5 part of tryptone, and add water to 100 parts , adjust the pH to be 7.0 to make liquid medium I;

[0043] Preparation of liquid medium II: weigh 1.2 parts of magnesium sulfate heptahydrate, 0.2 parts of potassium chloride, 2.4 parts of sodium chloride, 0.3 parts of sodium citrate, 0.2 parts of ammonium chloride, 0.5 parts of yeast extract powder, 0.15 parts of pancreatic Peptone, 0.7 part of starch, 0.5 part of glucose, add water to 100 parts, adjust pH to 7.0 to prepare liquid medium II.

Embodiment 3

[0045] Preparation of liquid medium I: Weigh 1 part of magnesium sulfate heptahydrate, 0.2 part of potassium chloride, 2.47 parts of sodium chloride, 0.3 part of sodium citrate, 1 part of yeast extract powder, 0.5 part of tryptone, and add water to 100 parts , adjust the pH to be 7.5 to make liquid medium I;

[0046] Preparation of liquid medium II: weigh 1.2 parts of magnesium sulfate heptahydrate, 0.2 parts of potassium chloride, 2.4 parts of sodium chloride, 0.3 parts of sodium citrate, 0.2 parts of ammonium chloride, 0.5 parts of yeast extract powder, 0.15 parts of pancreatic Peptone, 0.7 part of starch, 0.5 part of glucose, add water to 100 parts, adjust pH to 7.5 to prepare liquid medium II.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com