Homogeneous crosslinking beta-cyclodextrin/wolfram carbine composite microsphere and method of producing the same

A technology of composite microspheres and cyclodextrins, which is applied in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc. Simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

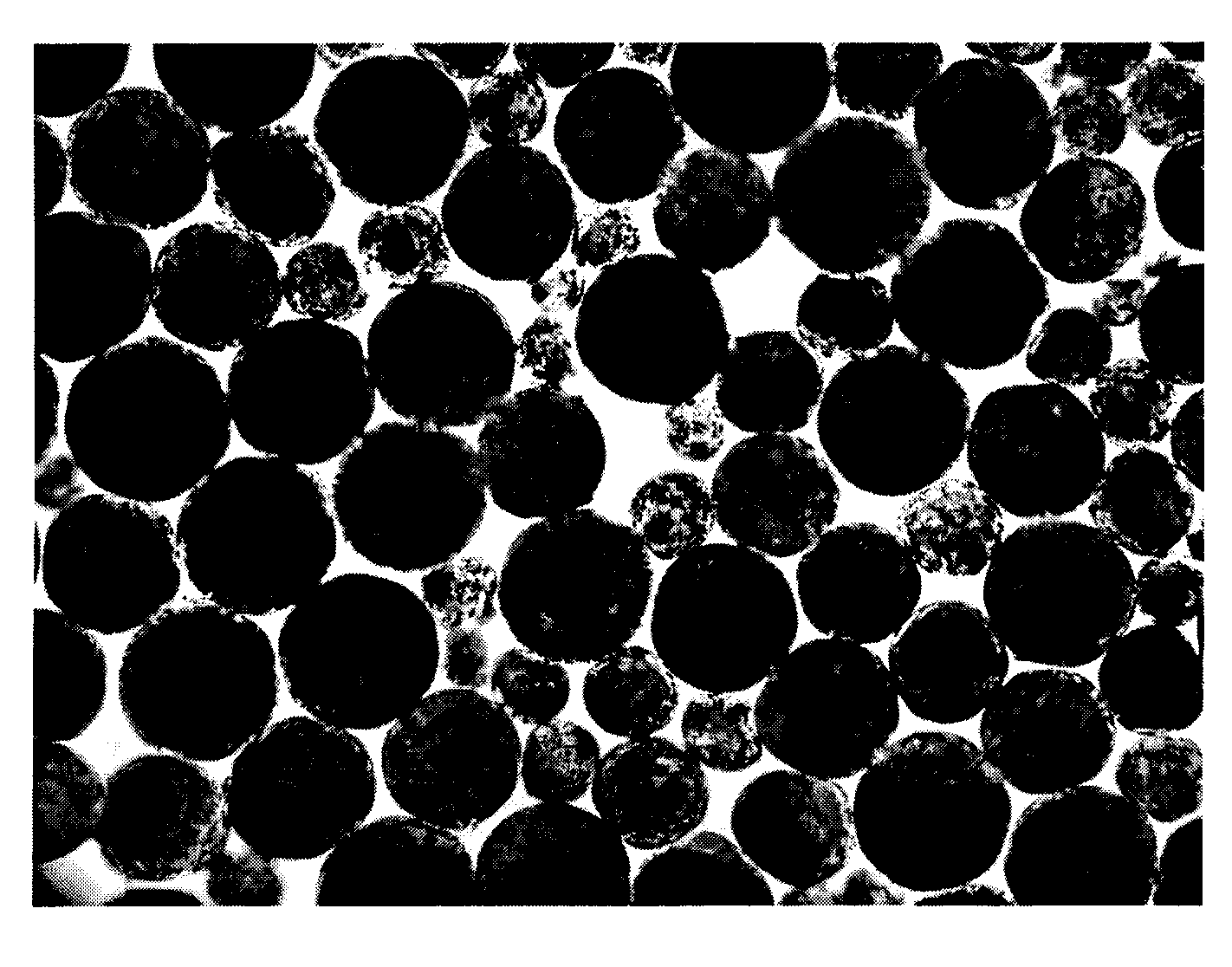

[0029] At 60°C, mix 8g of β-cyclodextrin and 40g of 20% aqueous sodium hydroxide solution to prepare a solution, add 8g of epichlorohydrin dropwise to the solution for 30min under mechanical stirring, and then continue stirring for 30min to obtain Viscose liquid; add 14g tungsten carbide powder to this viscose liquid and mix and stir evenly. Under the condition of 50°C and mechanical stirring speed of 300rpm, add 42g high-speed vacuum pump oil and 126g liquid paraffin oil dispersion phase, and Add 0.84g of polyoxyethylene sorbitan monooleate as a dispersant, stir for 15min, then add 2.5g of epichlorohydrin, and stir for 120min at 50°C with a mechanical stirring speed of 300rpm to obtain a black Homogeneous composite microspheres; cooled to 20°C, then mixed evenly with 0.5 times the volume of n-hexane, filtered under reduced pressure, filtered out the composite microspheres from the oil dispersed phase, and then separated with 2 times the volume of n-hexane After washing twice,...

Embodiment 2

[0031]At 90°C, mix 24g of β-cyclodextrin and 40g of 40% aqueous sodium hydroxide solution to prepare a solution, add 16g of epichlorohydrin dropwise to the solution for 45min under mechanical stirring, and then continue stirring for 120min to obtain Viscose liquid; add 120g of tungsten carbide powder to the viscose liquid and mix and stir evenly. Under the condition of 70°C and mechanical stirring speed of 450rpm, add 266g of high-speed vacuum pump oil and 133g of liquid paraffin oil dispersion phase, and Add 6.0g of polyoxyethylene sorbitan monooleate as a dispersant, stir for 30min, then add 30g of epichlorohydrin, and stir for 180min at 70°C with a mechanical stirring speed of 450rpm to obtain a black homogeneous Quality-type composite microspheres; cooled to 30°C, then mixed evenly with 1-fold volume of n-hexane, suction-filtered under reduced pressure, and the composite microspheres were filtered out from the oil dispersion phase, and then divided into 3 with 4-fold volume...

Embodiment 3

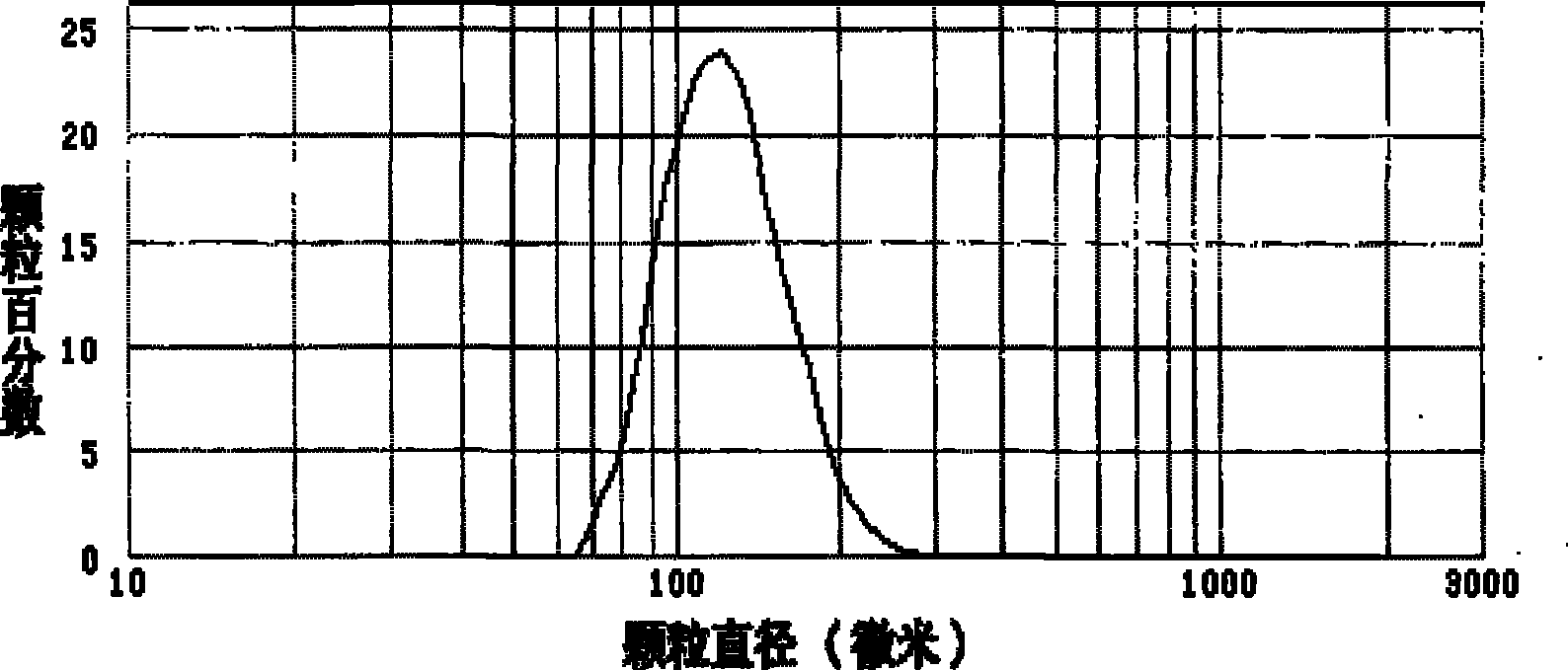

[0033] At 80°C, mix 20g of β-cyclodextrin and 40g of 25% aqueous sodium hydroxide solution to prepare a solution, add 10g of epichlorohydrin dropwise to the solution under mechanical stirring for 30min, and then continue stirring for 60min to obtain Viscose liquid; add 30g of tungsten carbide powder to the viscose liquid and mix and stir evenly. Under the condition of 60°C and mechanical stirring speed of 400rpm, add 90g of high-speed vacuum pump oil and 200g of liquid paraffin oil dispersion phase, and Add 2.5g of polyoxyethylene sorbitan monooleate as a dispersant, stir for 30min, then add 10g of epichlorohydrin, and stir for 150min at 60°C with a mechanical stirring speed of 400rpm to obtain a black homogeneous Qualitative composite microspheres; suction filtration, washing, neutralization, sieving and flotation according to the method in Example 2 to obtain 72 mL of composite microspheres with a particle size between 75 and 180 μm and a density of 1.4 g cm -3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com