Interior sulfhydryl functional iron-containing meso-porous titanium oxide and preparation method thereof

A mesoporous titanium oxide and functionalization technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. The amount of impurities is not completely controllable, etc., to achieve the effect of good biocompatibility and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

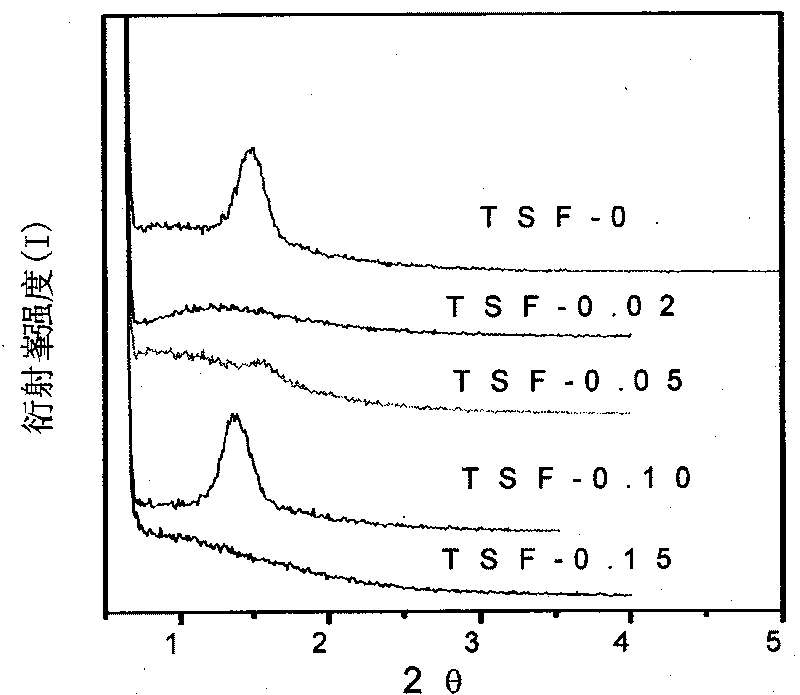

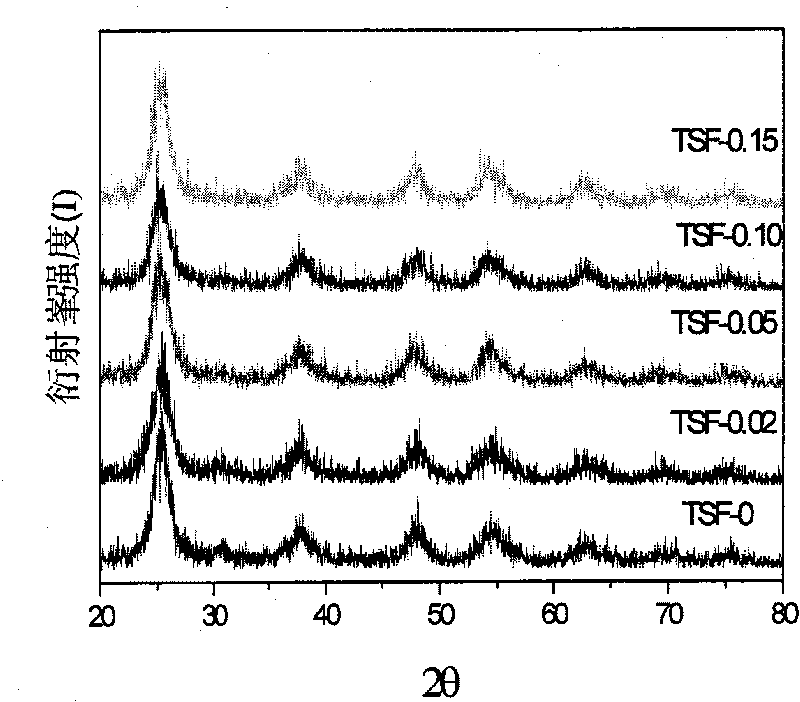

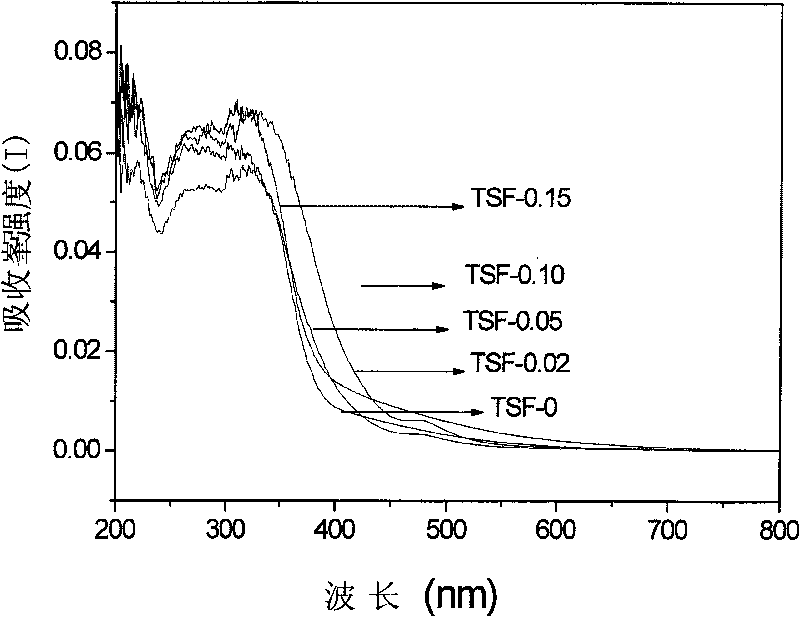

[0030] 0.02g Fe(NO 3 ) 3 9H 2O was dissolved in 20 ml of absolute ethanol, stirred to form a uniform solution, 1 g of nonionic surfactant P123 was added, and stirred in a constant temperature water bath at 40 degrees Celsius for 20 minutes until P123 was dissolved to form a clear solution. Then 0.06 g of mercaptopropyl-triethoxy silylating agent MPTES was added, and stirred at 40° C. for 2 h to form a sol. Add 3.40 g of butyl titanate to this sol, stir at 40 degrees Celsius for 2 hours, then add dropwise 22 ml of anhydrous ethanol-water mixed solution [absolute ethanol: water = 10: 1.0 (V / V), Containing 20 ml of absolute ethanol and 2 ml of deionized water], stirred in a water bath at 40°C for 24 hours, evaporated to dryness in a water bath at 80°C for 40 hours, and obtained an orange gel, extracted with 150 ml of ethanol for 12 hours, and filtered to separate a solid sample. The obtained sample was transferred to an autoclave, crystallized in 0.1 M, 40 ml HCl solution at 1...

Embodiment 2

[0032] 0.05g Fe(NO 3 ) 3 9H 2 O was dissolved in 20 ml of absolute ethanol, stirred to form a uniform solution, 1 g of nonionic surfactant P123 was added, and stirred in a constant temperature water bath at 40 degrees Celsius for 20 minutes until P123 was dissolved to form a clear solution. Then 0.06 g of mercaptopropyl-triethoxy silylating agent MPTES was added, and stirred at 30° C. for 2 h to form a sol. Add 3.40 g of butyl titanate to this sol, stir at 40 degrees Celsius for 2 hours, then add dropwise 22 ml of anhydrous ethanol-water mixed solution [absolute ethanol: water = 10: 1.0 (V / V), Containing 20 ml of absolute ethanol and 2 ml of deionized water], stirred in a water bath at 40°C for 24 hours, evaporated to dryness in a water bath at 80°C for 40 hours, and obtained an orange gel, extracted with 150 ml of ethanol for 12 hours, and filtered to separate a solid sample. The obtained sample was transferred to an autoclave, crystallized in 0.1 M, 40 ml HCl solution at ...

Embodiment 3

[0034] 0.10g Fe(NO 3 ) 3 9H 2 O was dissolved in 20 ml of absolute ethanol, stirred to form a uniform solution, 1 g of nonionic surfactant P123 was added, and stirred in a constant temperature water bath at 40 degrees Celsius for 20 minutes until P123 was dissolved to form a clear solution. Then 0.06 g of mercaptopropyl-triethoxy silylating reagent MPTES was added, and stirred at 50 degrees Celsius for 2 hours to form a sol. Add 3.40 g of butyl titanate to this sol, stir at 40 degrees Celsius for 2 hours, then add dropwise 22 ml of anhydrous ethanol-water mixed solution [absolute ethanol: water = 10: 1.0 (V / V), Containing 20 ml of absolute ethanol and 2 ml of deionized water], stirred in a water bath at 40°C for 24 hours, evaporated to dryness in a water bath at 80°C for 40 hours, and obtained an orange gel, extracted with 150 ml of ethanol for 12 hours, and filtered to separate a solid sample. The obtained sample was transferred to an autoclave, crystallized in 0.1 M, 40 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com