Ultrasonic chemical in-situ preparation method for phthalocyanine-sensitized vanadate nano-powder

A technology of phthalocyanine-sensitized bismuth vanadate and ultrasonic chemistry, which is applied in chemical instruments and methods, catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of inability to provide uniform bismuth vanadate Nano-powder, sensitization modification, poor utilization effect, unsatisfactory photocatalytic performance, etc., to achieve the effect of increasing photocatalytic performance, increasing light absorption and photon efficiency, and inhibiting recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 10mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 100ml of 2mol / L nitric acid solution, and 10mmol of NH 4 VO 3 Dissolve in 100ml of distilled water; then add 20mg of sulfonated cobalt phthalocyanine (CoPcTs) to Bi(NO 3 ) 3 In the solution, add an appropriate amount of NaOH solution, control its pH value to 1, adjust the temperature of the mixed solution to 50°C, and keep the temperature for 4h; finally add NH 4 VO 3 The aqueous solution was slowly added dropwise into the Bi(NO 3 ) 3 solution, and the solution was ultrasonicated for 2 hours at the same time, the ultrasonic frequency and power were 40KHz and 150W, respectively, centrifuged, washed, and dried in vacuum at 60°C for 12 hours to prepare a cobalt phthalocyanine-sensitized bismuth vanadate photocatalyst powder sample.

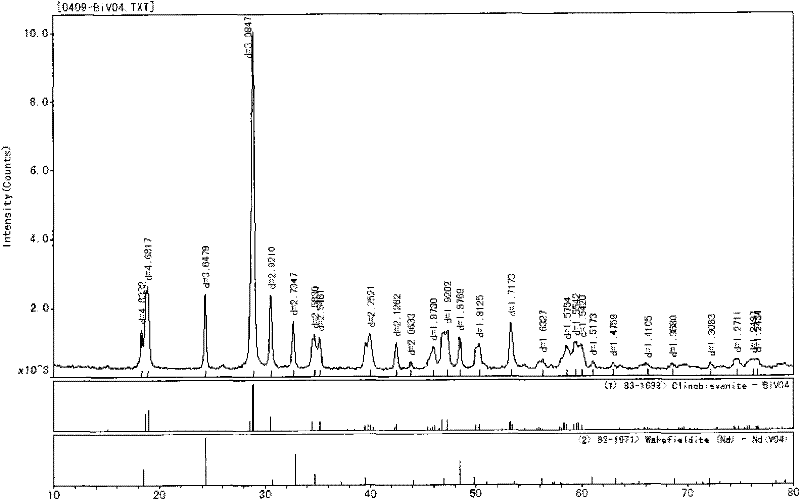

[0030] In the cobalt phthalocyanine sensitized bismuth vanadate nanometer powder, the sensitizer accounts for about 0.6% of the total mass of the powder. Using JADE5 software analysis, the r...

Embodiment 2

[0034] 10mmol Bi(OH) 3 Dissolve in 50ml of 5mol / L hydrochloric acid solution, dissolve 10mmol of bis(1,1-cyclobutanedicarboxylic acid)vanadyl in 50ml of distilled water; then add 100mg of sulfonated copper phthalocyanine (CuPcTs) to Bi(OH) 3 In the solution, add an appropriate amount of ammonia water, adjust the pH value of the solution to 4, adjust the temperature of the mixed solution to 95 ° C, and keep the temperature for 2 hours; finally, slowly add the bis(1,1-cyclobutanedicarboxylic acid) vanadyl solution dropwise To Bi(OH) 3 solution, and the solution was ultrasonicated for 4 hours at the same time, the ultrasonic frequency and power were 40KHz and 150W, respectively, centrifuged, washed, and dried in vacuum at 100°C for 6 hours to prepare copper phthalocyanine sensitized BiVO 4 Photocatalyst powder samples.

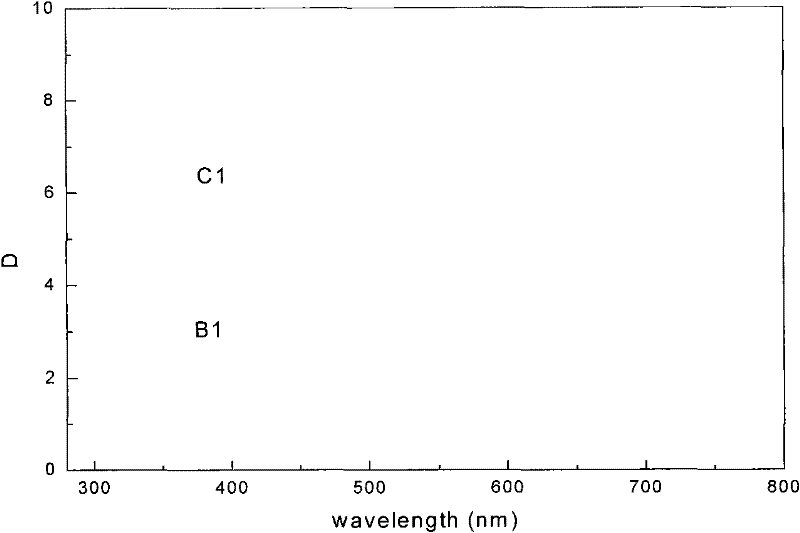

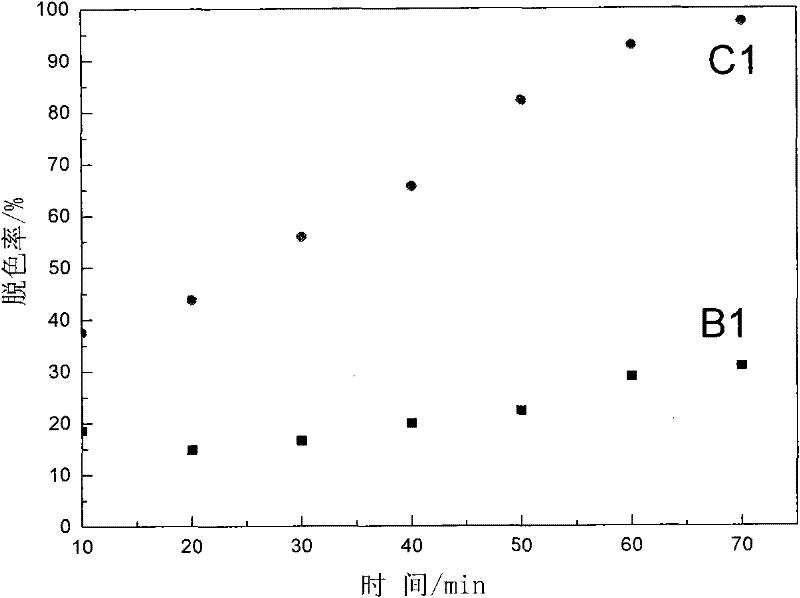

[0035] In this copper phthalocyanine sensitized BiVO 4 In the nanometer powder, the sensitizer accounts for about 3% of the total mass of the powder. The pho...

Embodiment 3

[0037] Dissolve 30mmol of bismuth subsalicylate in 100ml of a mixed acid solution of 3mol / L hydrochloric acid and nitric acid, dissolve 30mmol of sodium metavanadate in 100ml of distilled water; then add 80mg of sulfonated iron phthalocyanine (FePcTs) to the above basic formula Add an appropriate amount of triethanolamine to the bismuth salicylate solution, control its pH value to 2, adjust the temperature of the mixed solution to 60°C, and keep the temperature for 3 hours; finally, slowly add the aqueous solution of sodium metavanadate into the alkaline water Bismuth sylate solution was ultrasonicated for 3 hours at the same time, the ultrasonic frequency and power were 40KHz and 150W respectively, centrifuged, washed, and dried in vacuum at 90°C for 8 hours to prepare iron phthalocyanine sensitized BiVO 4 Photocatalyst powder samples.

[0038] In this phthalocyanine iron sensitized BiVO 4 In the nanometer powder, the sensitizer accounts for about 0.8% of the total mass of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com