Method for preparing carbon-coating type lithium titanate for lithium ion battery

A carbon-coated lithium titanate and lithium-ion battery technology, which is applied in the field of lithium-ion battery anode materials, can solve problems such as poor electronic conductivity and poor rate charge and discharge performance, achieve firm and tight contact, improve electronic conductivity, Effect of improving rate charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

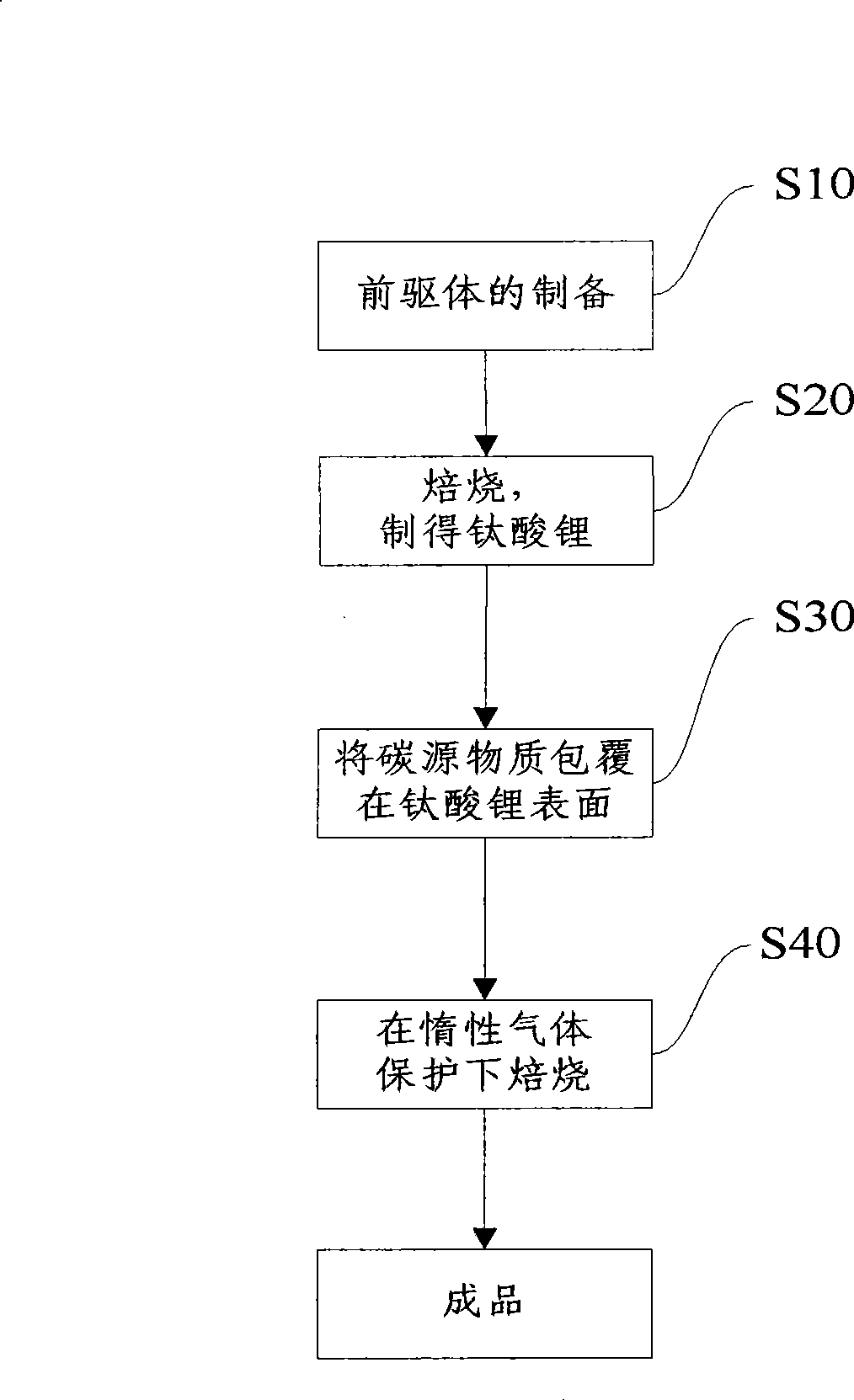

[0029] First, if figure 1 Shown, preparation method of the present invention comprises the following steps:

[0030] 1) Lithium salt and titanium dioxide are weighed according to the ratio of molar ratio Li:Ti=(0.81~0.87):1, and described lithium salt is lithium carbonate, lithium hydroxide, lithium oxide, lithium nitrate, lithium phosphate, lithium chlorate and one or several kinds of lithium oxalate, then add dispersant distilled water, absolute ethanol or acetone, the mass ratio of dispersant to ball milling mixture is (1~3):4, fully mix by ball milling, ball milling time is 2 ~10 hours, and then vacuum-dried at 80~120° C. for 12~36 hours to prepare the precursor (S10);

[0031] 2) Calcining the prepared precursor at 750-1000°C for 8-20 hours to prepare lithium titanate (S20);

[0032] 3) Coating a carbon source material soluble in absolute ethanol or acetone on the surface of the prepared lithium titanate (S30) by dipping and evaporating to dryness, the carbon source mat...

Embodiment 1

[0039] Take lithium carbonate 25.9g, TiO 2 66.1g, 45ml of dispersant water, placed in a ball mill jar, at a speed of 40Hz, mixed by ball mill for 4h, and dried to obtain the precursor; the precursor was roasted in a muffle furnace at a temperature of 900°C for 14h to obtain titanium Lithium Oxide. The median diameter D50 of the product particles was measured to be 16.1 μm, and the specific surface area was 2.9 m 2 / g.

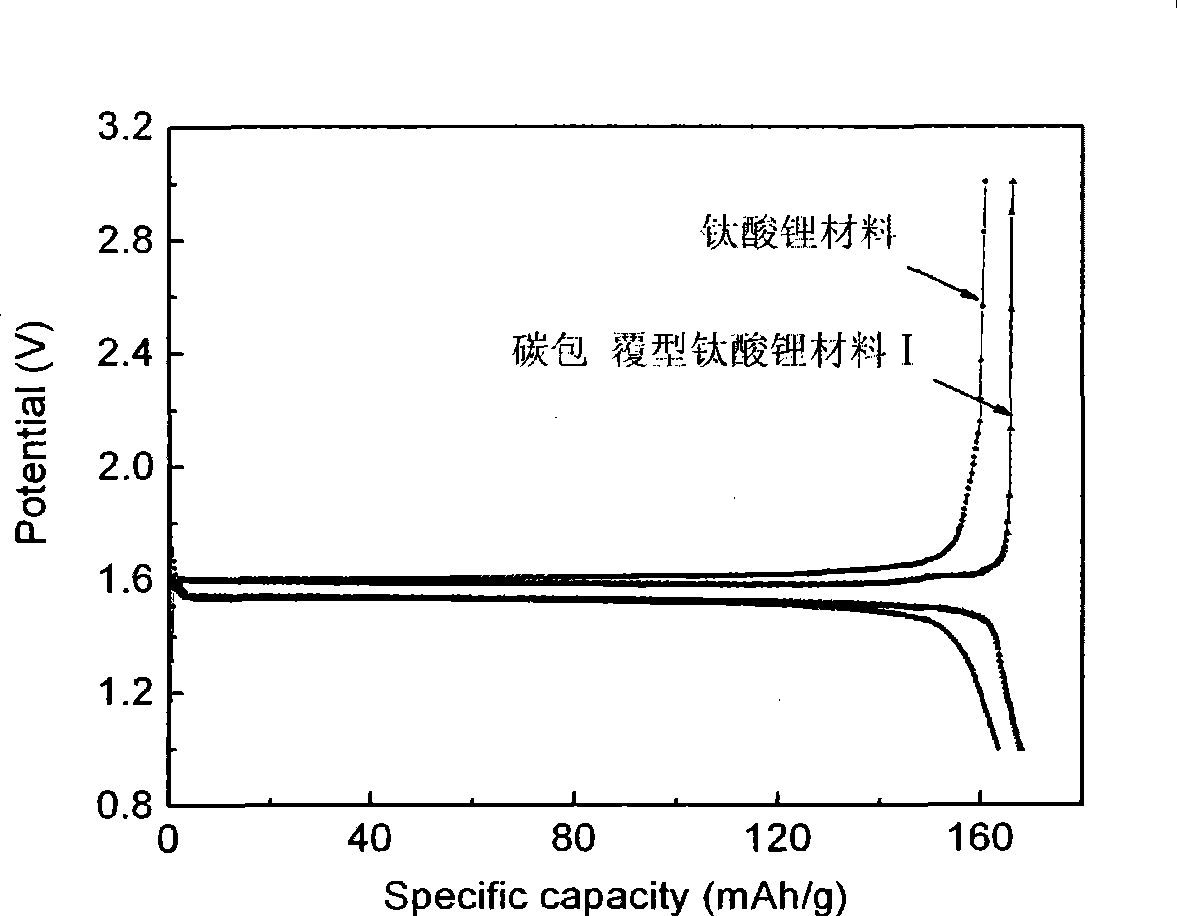

[0040] The selected carbon source material is phenolic resin, take 5.0g of phenolic resin, add it to 100ml of absolute ethanol, 70oC water bath, mechanically stir for 30 minutes to fully dissolve the resin, then slowly add 30g of lithium titanate powder, and stir quickly until the ethanol evaporates to dryness So far, the obtained paste is placed in a tube furnace and roasted under the protection of argon, the roasting temperature is 850°C, and the roasting time is 2h. The obtained product is denoted as carbon-coated lithium titanate material I. It is measu...

Embodiment 2

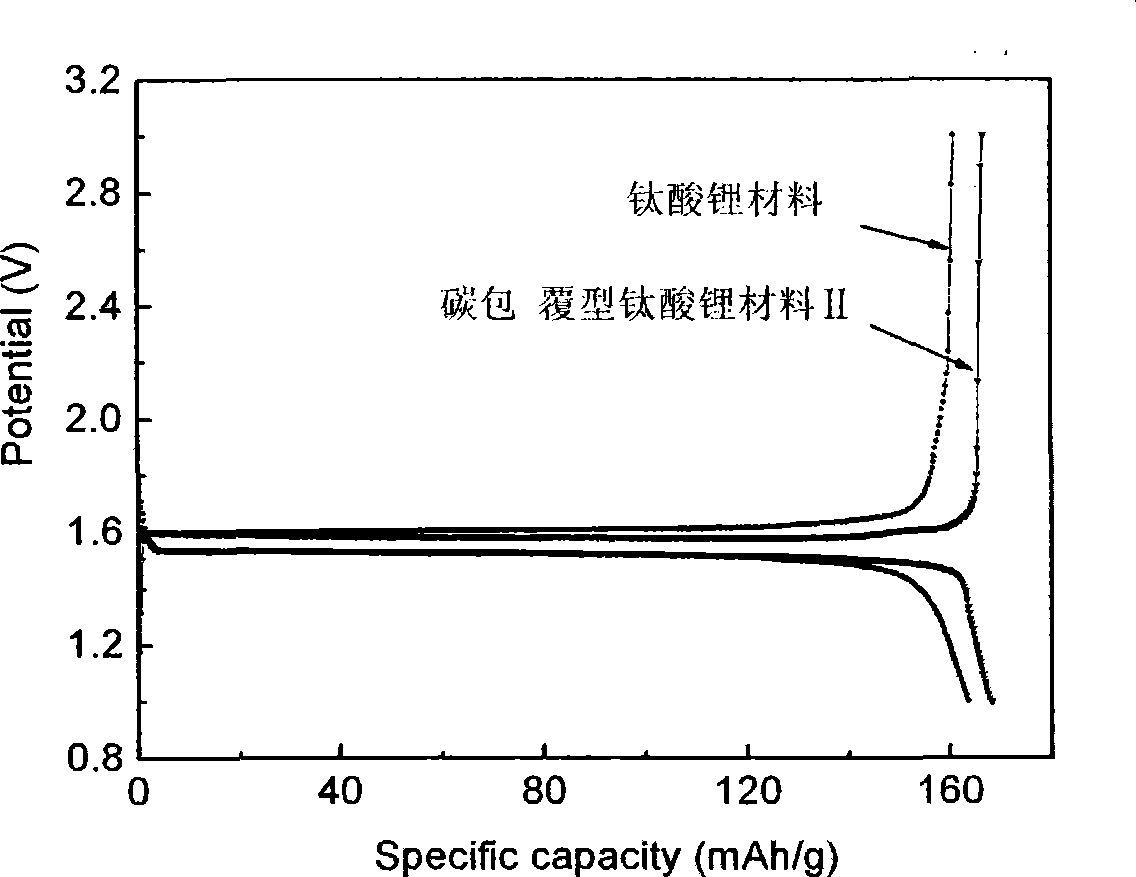

[0042] Take LiOH·H 2 O11.1g, TiO 2 26.1g, 5.0g of phenolic resin, 17ml of anhydrous ethanol as a dispersant, placed in a ball mill jar, with a speed of 40Hz, ball milled for 4h, dried to obtain the precursor, the precursor was placed in a tube furnace for roasting, nitrogen protection, temperature 900° C. for 14 hours to obtain carbon-coated lithium titanate material II. It is measured that the coating amount of carbon in the carbon-coated lithium titanate material II is 5.0%, the median diameter D50 of the product particles is 11.4 μm, and the specific surface is 3.8 m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com