Method for preparing superfine spherical cobalt powder

A spherical and cobalt powder technology, applied in the field of preparation of ultra-fine spherical cobalt powder, can solve problems such as large consumption, and achieve the effects of high production efficiency, high efficiency and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

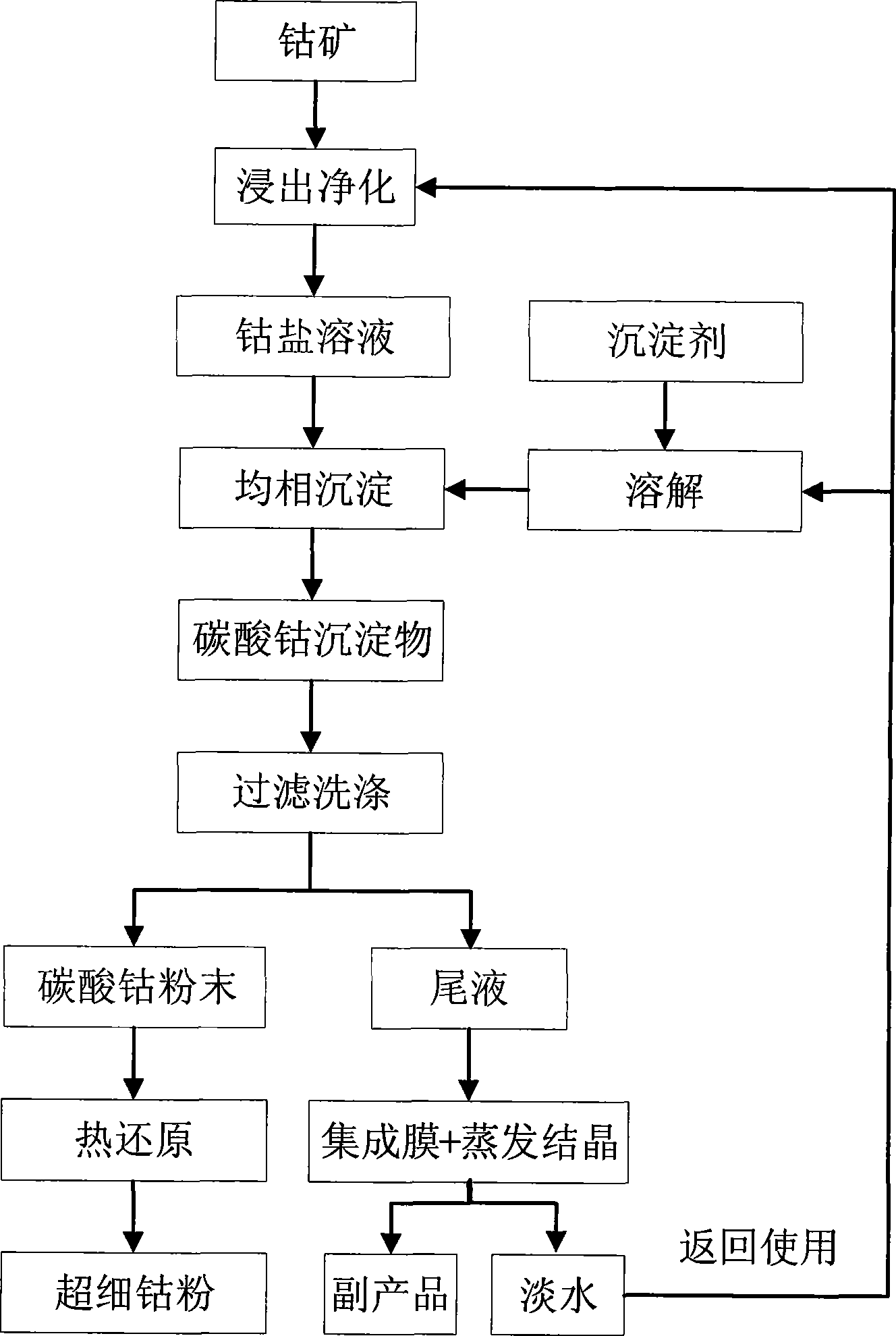

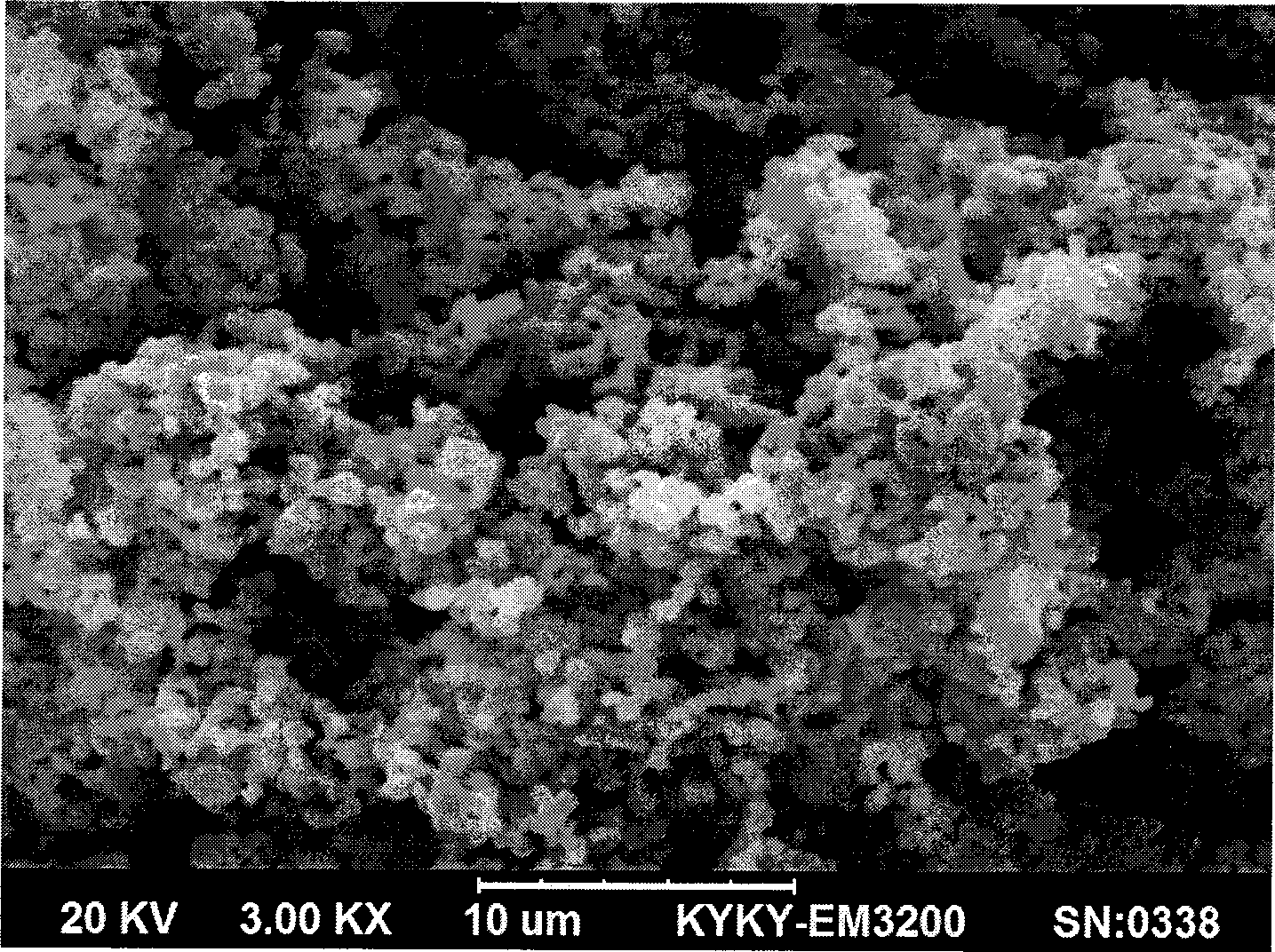

[0030] Embodiment 1, with reference to attached figure 1 , 2 .

[0031] Using cobalt-containing ore as raw material, after leaching and purification, a high-purity cobalt-containing cobalt chloride solution of 60-160g / L is obtained, and polyvinylpyrrolidone (PVP) is added to the above-mentioned cobalt solution according to 0.05-5% of the cobalt mass. ), polyvinyl alcohol (PVA) or two in any proportion, as a homogeneous cobalt salt solution; ammonium bicarbonate is used as a precipitating agent, which is dissolved and filtered to form an 80-200g / L precipitating agent solution. Add the homogeneous cobalt salt solution and the precipitant solution with a theoretical reaction volume of 1.1 to 1.3 times into the reactor by co-current feeding method, and use the distributed control system (DCS) to control the reaction temperature to 40 to 90°C and the reaction pH to 6.0 to 8.5 , the feeding speed is 200-1000L / h, the stirring speed is 800-1200rpm, and the precipitate of ultra-fine ...

Embodiment 2

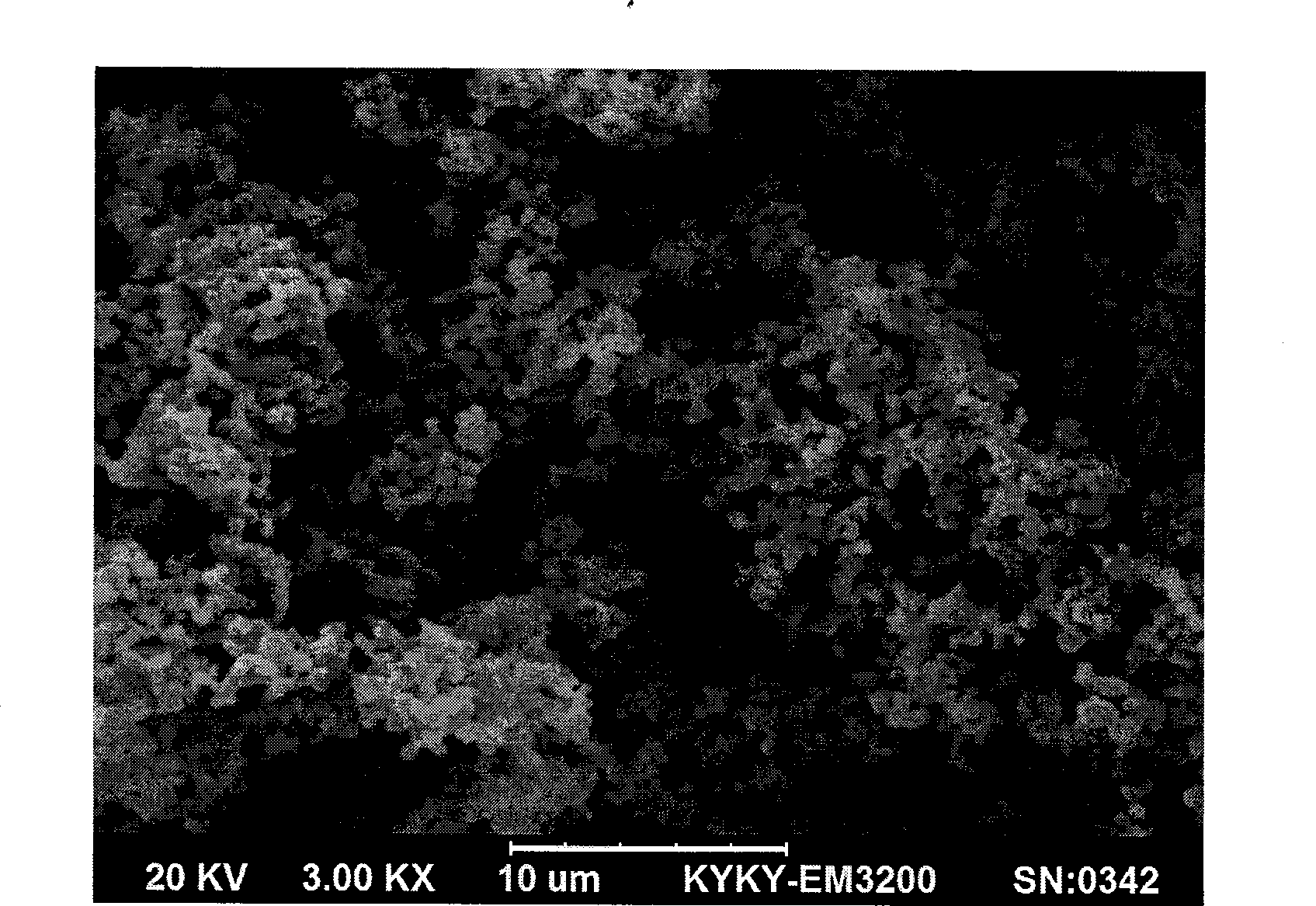

[0032] Embodiment 2, with reference to attached figure 1 , 3 .

[0033]Using cobalt-containing ore as raw material, after leaching and purification, a high-purity cobalt-containing cobalt sulfate solution of 60-160g / L is obtained, and cetyltrimethyl is added to the above-mentioned cobalt solution according to 0.05-5% of the cobalt mass One of ammonium bromide (CTAB), polyethylene glycol PEG (1000) or two of them in any ratio, as a cobalt salt solution; ammonium bicarbonate is used as a precipitating agent, and 80-200g is prepared after dissolving and filtering / L precipitant solution. Add the homogeneous cobalt salt solution and the precipitant solution with a theoretical reaction volume of 1.1 to 1.3 times into the reaction kettle by using the co-current feeding method, and use the distributed control system (DCS) to control the reaction temperature to 40-90°C and the reaction pH value to be 6.0 to 8.5 , the feeding speed is 200-1000L / h, the stirring speed is 800-1200rpm, ...

Embodiment 3

[0034] Embodiment 3, with reference to attached figure 1 , 4 .

[0035] Using cobalt-containing ore as raw material, after leaching and purification, a high-purity cobalt-containing cobalt nitrate solution of 60-160g / L is obtained, and polyvinylpyrrolidone (PVP) is added to the above-mentioned cobalt solution according to 0.05-5% of the cobalt mass , polyvinyl alcohol (PVA), water-soluble starch, or two of them in any ratio, as a homogeneous cobalt salt solution; using ammonium carbonate as a precipitant, it is dissolved and filtered to form a 80-200g / L precipitate agent solution. Add the homogeneous cobalt salt solution and the precipitant solution with a theoretical reaction volume of 1.1 to 1.3 times into the reaction kettle by using the co-current feeding method, and use the distributed control system (DCS) to control the reaction temperature to 40-90°C and the reaction pH value to be 6.0 to 8.5 , the feeding speed is 600-1000L / h, the stirring speed is 800-1200rpm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

| Fisherman's particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com