Magnetic field sensor utilizing ferromagnetic nanometer ring strong magnetic resistance effect

A magnetic field sensor and giant magnetoresistance technology, applied in instruments, measuring magnetic variables, measuring devices, etc., can solve the problems of small output signal amplitude, difficulty in ensuring consistency, small output signal, etc., to achieve large changes in magnetoresistance, production Simple, large output signal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

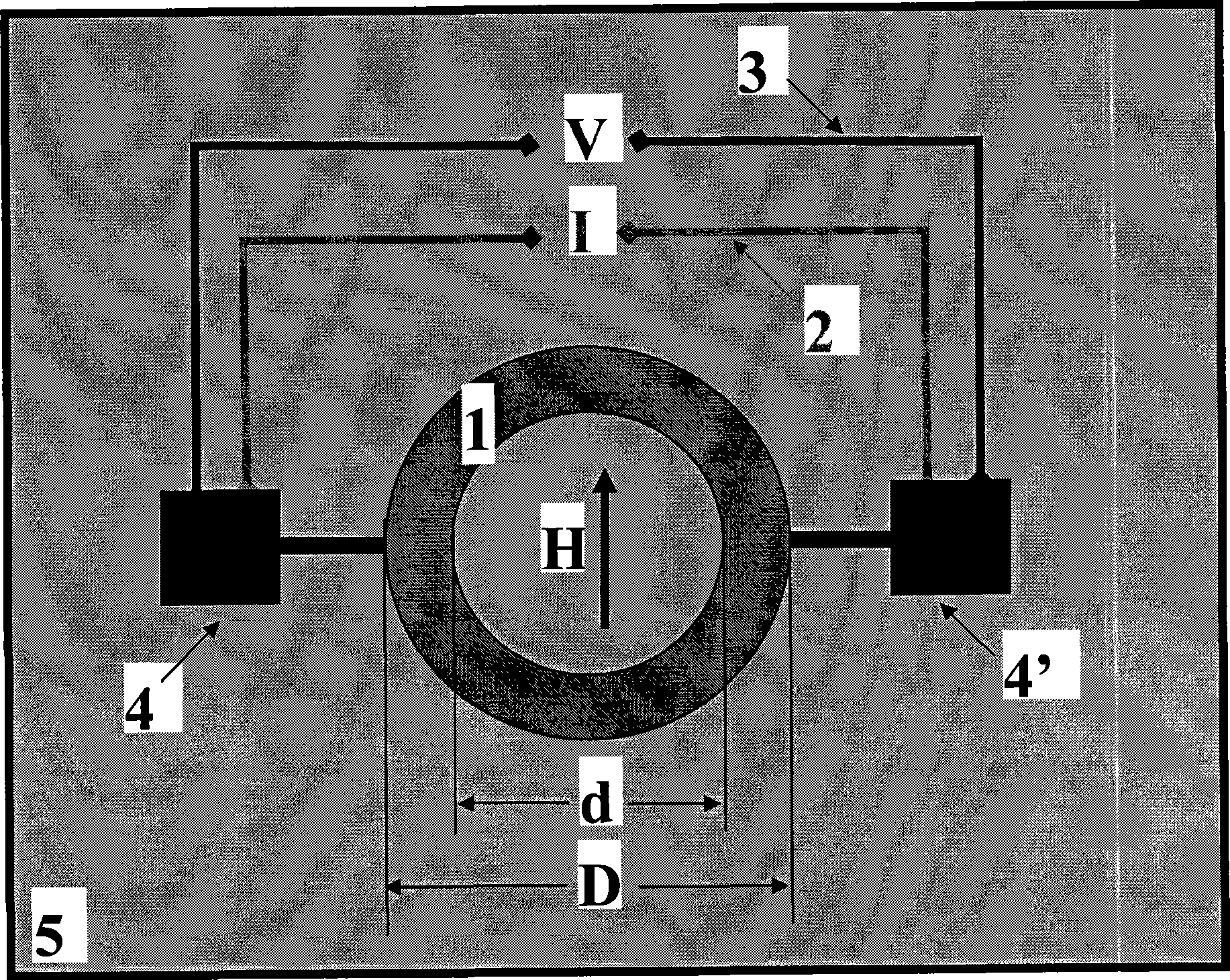

[0018] A magnetic field sensor composed of cobalt-iron alloy ferromagnetic nano-rings and copper measuring leads was fabricated on a quartz glass substrate.

[0019] The first step is to first select the quartz glass substrate 5, cut it to a size of 10 mm in length, 10 mm in width, and 0.5 mm in thickness, ultrasonically clean it with acetone, then ultrasonically clean it with deionized water, and finally clean it with absolute ethanol ultrasonically, and then clean it with high-purity nitrogen gas. Blow dry and set aside; the second step is to prepare the cobalt-iron alloy ferromagnetic nano-ring 1 on the substrate, put the substrate into the coating chamber of the magnetron sputtering coating equipment, and pump the coating chamber to 2×10 -5 The vacuum degree of Pascal is deposited on the substrate with a magnetron sputtering method to deposit a 40-nanometer thick cobalt-iron alloy film, and the working gas is argon gas of 0.8 Pascal, which is then taken out and coated on th...

Embodiment 2

[0023] A magnetic field sensor composed of cobalt metal magnetic nano-rings and copper-gold alloy measuring leads is fabricated on a single crystal silicon substrate.

[0024] The first step is to select a single crystal silicon substrate 5 and cut it to a size of 10 mm in length, 10 mm in width and 0.5 mm in thickness, ultrasonically clean it with acetone, then ultrasonically clean it with deionized water, and finally clean it with absolute ethanol ultrasonically. Blow dry with nitrogen and set aside; the second step is to prepare cobalt metal ferromagnetic nano-ring 1 on the substrate, put the substrate into the coating chamber of the magnetron sputtering coating equipment, and pump the coating chamber to 2×10 -5 The vacuum degree of Pascal is deposited on the substrate with a magnetron sputtering method to deposit a 40-nanometer thick cobalt metal film, and the working gas is argon gas of 0.8 Pascal, which is then taken out and coated on the deposited film with photoresist. ...

Embodiment 3

[0028] A magnetic field sensor composed of chromium dioxide ferromagnetic nano-rings and copper-zinc alloy measuring leads was fabricated on a single crystal silicon substrate.

[0029]The first step is to select a single crystal silicon substrate 5 and cut it to a size of 10 mm in length, 10 mm in width and 0.5 mm in thickness, ultrasonically clean it with acetone, then ultrasonically clean it with deionized water, and finally clean it with absolute ethanol ultrasonically. Blow dry with nitrogen and set aside; the second step is to prepare chromium dioxide ferromagnetic nano-ring 1 on the substrate, put the substrate into the coating chamber of the pulse laser coating equipment, and pump the coating chamber to 1×10 -7 The vacuum degree of Pascal, irradiate the chromium target with pulsed laser, pass through the oxygen of 400mTorr, deposit a chromium dioxide film with a thickness of 40 nanometers on the substrate, then take it out, coat the deposited film with photoresist, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com