Production method of ball valve core

A manufacturing method and valve core technology, which can be applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of increased cost of ball valve cores and the need for more materials for ball valve cores, saving materials and high yield , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the manufacture method of this ball valve spool, the metal plate 4 that selects to make the outer spherical shell 1 of ball valve spool 1 of the present invention is stainless steel plate, the thickness of stainless steel plate is about 1mm~1.5mm, according to the size of ball valve spool with cutting machine It is cut into the required length and its structure schematic diagram is as follows figure 1 shown;

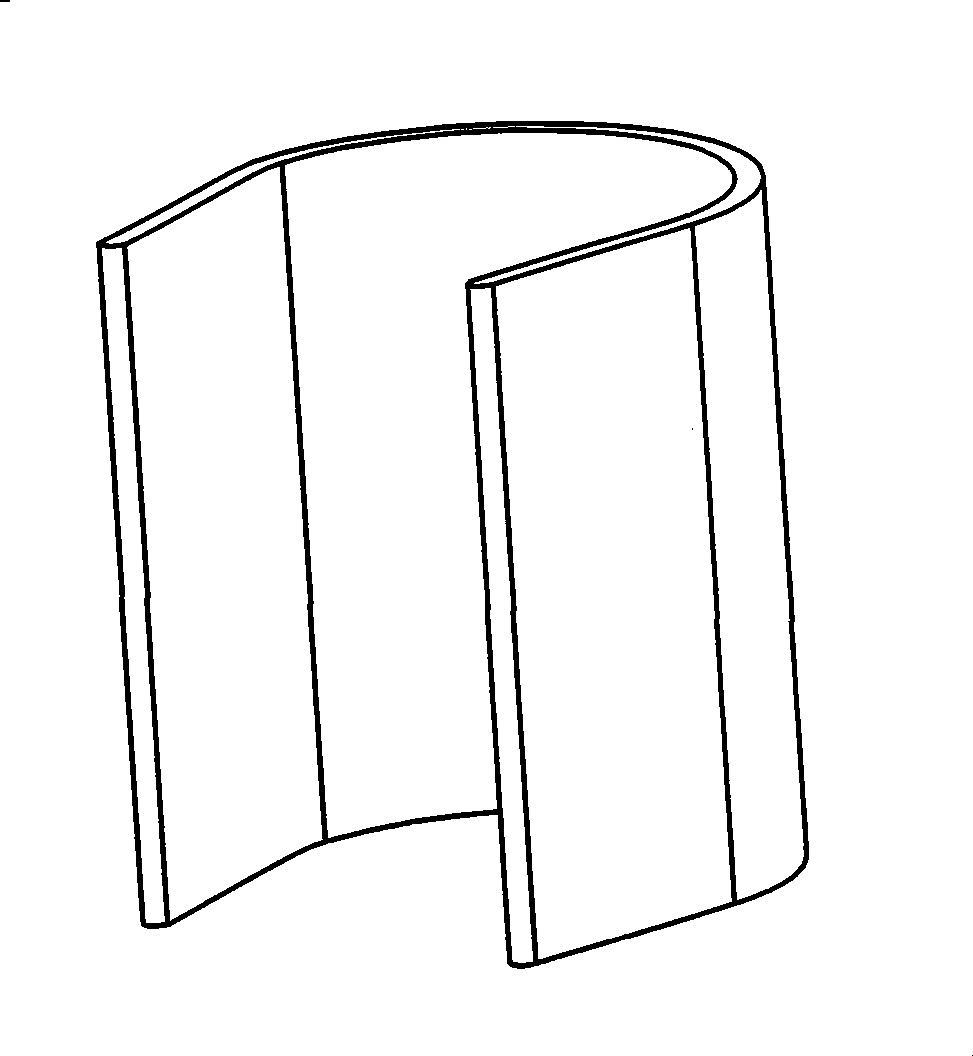

[0037] Select a suitable mold for making the metal round tube 5, put the stainless steel plate on the mold to bend it into a U shape, and then use a punch or punching machine on the mold to punch the U-shaped plate into a stainless steel round tube 5. Its structural diagram is as follows figure 2 and image 3 Shown; With welding machine, the pipe seam of stainless steel round pipe 5 is welded to form weld seam 51, and stainless steel round pipe 51 is put into spherical forming mold by extruding and shrinking at both ends of round pipe, and the middle part exp...

Embodiment 2

[0044] The plate 4 for making the outer spherical shell 1 is a copper plate, and the manufacturing process of the valve stem connection seat 2 is as follows: a mold is made according to the shape and size of the valve stem connection seat 2, and molten copper metal liquid is poured into the mold, and the mold After cooling at room temperature to form the green body of the valve stem connecting seat 2, it is demolded, and the green body of the valve stem connecting seat 2 undergoes surface polishing and deburring treatment to obtain the finished product of the valve stem connecting seat 2. The inner straight pipe 3 and the outer spherical shell 1 are fixedly connected together by performing circular seam welding on the connecting portion where the two ends of the inner straight pipe 3 and the outer spherical shell 1 meet. Other technological process is the same as embodiment 1, repeats no more.

Embodiment 3

[0046] The plate 4 for making the outer spherical shell 1 is a copper plate, and the manufacturing process of the valve stem connecting seat 2 is as follows: first make the valve stem connecting seat 2 body, and then mill the valve stem groove on the valve stem connecting seat 2 body by a milling machine After 21, the finished product of valve stem connecting seat 2 is obtained. Other technological process is the same as embodiment 1, repeats no more.

[0047] The wear resistance, hardness and toughness of the ball valve spool made by the above method can almost guarantee the strength required by the ball valve, but the strength of the valve stem groove 21 and the valve stem connection part can be strengthened, saving materials .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com