New elastic fiber and preparation method thereof

A fiber and composite fiber technology, applied in the field of polymer elastic fiber and its preparation, can solve the problems of poor shrinkage stability over time, limited applications, insufficient thermal shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of copolyester (HSPET) for high shrinkage fibers

[0039] Calculated by mass ratio, take 1 part of terephthalic acid (PTA), 0.042 part of isophthalic acid (IPA), 0.010 part of neopentyl glycol (DTG), 476 parts of ethylene glycol (EG) and 0.00032 part of polycondensation catalyst Sb 2 O 3 and 0.0003 parts of stabilizer H 3 PO 3 , stirred in a beating kettle to make a slurry. The above-mentioned slurry is gradually and continuously sent into the esterification reaction kettle to carry out semi-continuous direct esterification reaction in 2.5~3.0hr, and some pre-prepared ethylene terephthalate (containing IPA, DTG, etc.) has been prepared in the reaction kettle. ) melt to ensure that the esterification reaction can be carried out under normal pressure. The esterification reaction temperature is 255°C, and the reaction time is 175min. When the esterification reaction rate reaches more than 98%, the reaction product can be moved into the polyconden...

Embodiment 2

[0044] Example 2: Study of shrinkage properties of high shrinkage copolyester (HSPET).

[0045] The HSPET chips obtained in Example 1 were pre-crystallized with 150° C. dehumidifying hot air, with a large air volume for 20 minutes, and then dried with 140° C. dehumidifying hot air for 5 hours, and the moisture content was less than 40ppm and then sent to the screw extruder. The spinning melt temperature was 285°C; the spinning-drawing-setting process was completed by one-step spinning-drawing process (FDY); the temperature of the first hot roller (DR1) was 80°C and the speed was 1650m / min; the second hot roller (DR2) ) temperature 90 ℃, speed 4700m / min; winding speed 4600m / min. The obtained fiber had a linear density of 30 dtex, a breaking strength of 4.20 cN / dtex, an elongation at break of 26%, a boiling water shrinkage rate of 66%, and a dry heat shrinkage rate of 53% at 180°C.

Embodiment 3

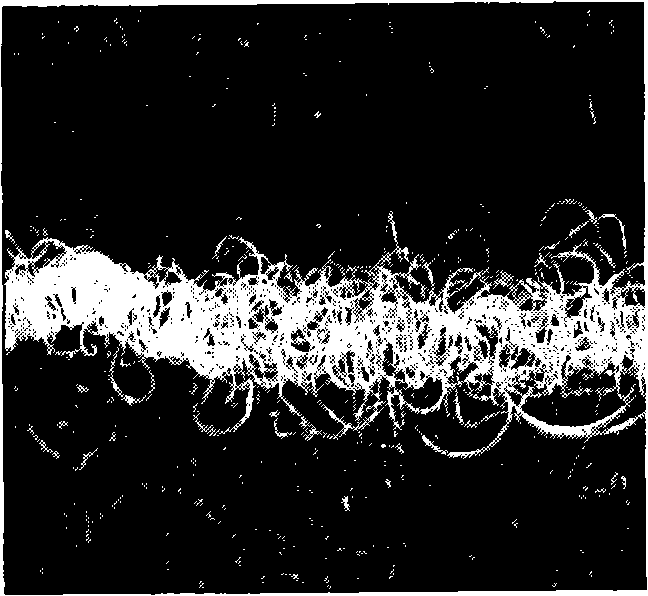

[0046] Example 3: Preparation of Side-by-Side Composite Fibers

[0047] The high shrinkage copolyester (HSPET) prepared in the above Example 1 and polytrimethylene terephthalate (PTT) with an intrinsic viscosity of 0.91 dl / g were used as raw materials, and the volume ratio of HSPET / PTT was 50 / 50. The two kinds of chips were dried first, and then the side-by-side composite fibers were spun. The spinning machine is a compound twin-screw extruder, the screw diameter is 30mm, the length-diameter ratio is 25:1, the main and auxiliary double-box structure, the spinning spinneret is 24 holes, and the spinneret hole diameter is 0.25mm. The spinning box temperature was 276°C, and the spinning speed was 800m / min. The nascent fiber is drawn and set on a flat drawing machine, the stretching temperature is 90°C, the stretching ratio is 3.8 times, and the setting temperature is 150°C. The linear density of the finished fiber is 171dtex / 48f, the breaking strength is 1.86cN / dtex, and the br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com