Method for preparing antimicrobial type epidermis repair material

An epidermal repair and antibacterial agent technology, applied in the field of preparation of antibacterial epidermal repair materials, can solve the problems of limited use of organic antibacterial agents, human and environmental hazards, poor antibacterial effect, etc., and achieves high migration speed and safety. High, long-acting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

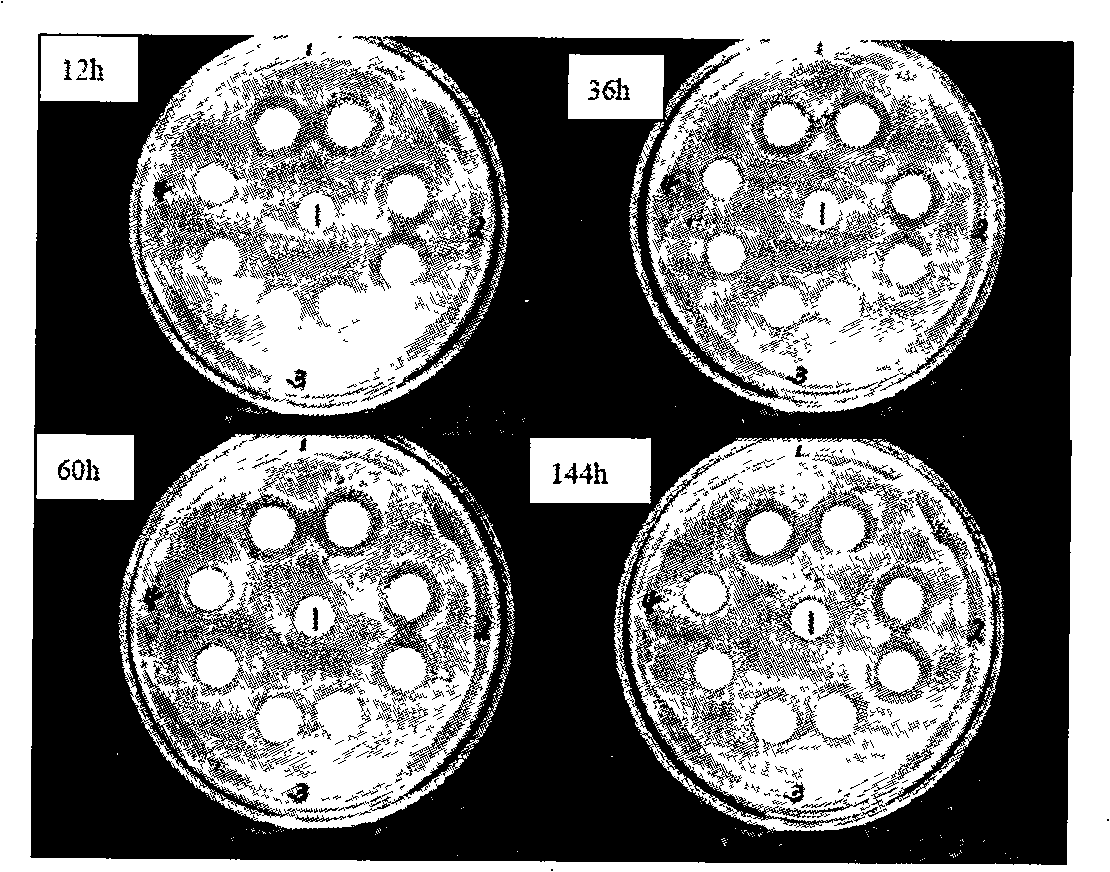

[0022] Embodiment 1: the impact of antibacterial agent concentration on material antibacterial property

[0023] Remove the terminal peptide through enzymatic digestion to obtain incomplete collagen without antigenicity, dissolve the collagen swelling solution and chitosan respectively with 0.05M acetic acid, and prepare a collagen solution with a concentration of 0.6% (wt) and a concentration of 0.6% (wt) Chitosan solution, then add silver-loaded inorganic antibacterial agent powder HN-300 with sodium phosphate crystals as the carrier in the chitosan solution, after stirring, ultrasonication, and stirring again, mix with the chitosan solution at a ratio of 9:1 The mass ratio is fully stirred and mixed to obtain the collagen / chitosan / HN-300 dispersion liquid, wherein the content of HN-300 is 10%, 7.5%, 5%, 2.5% (wt), and the prepared dispersion liquid is pressed by 3cm 2 / g Spread the film evenly on a polytetrafluoroethylene plate, and place it in a 37°C oven to dry. Soak in ...

Embodiment 2

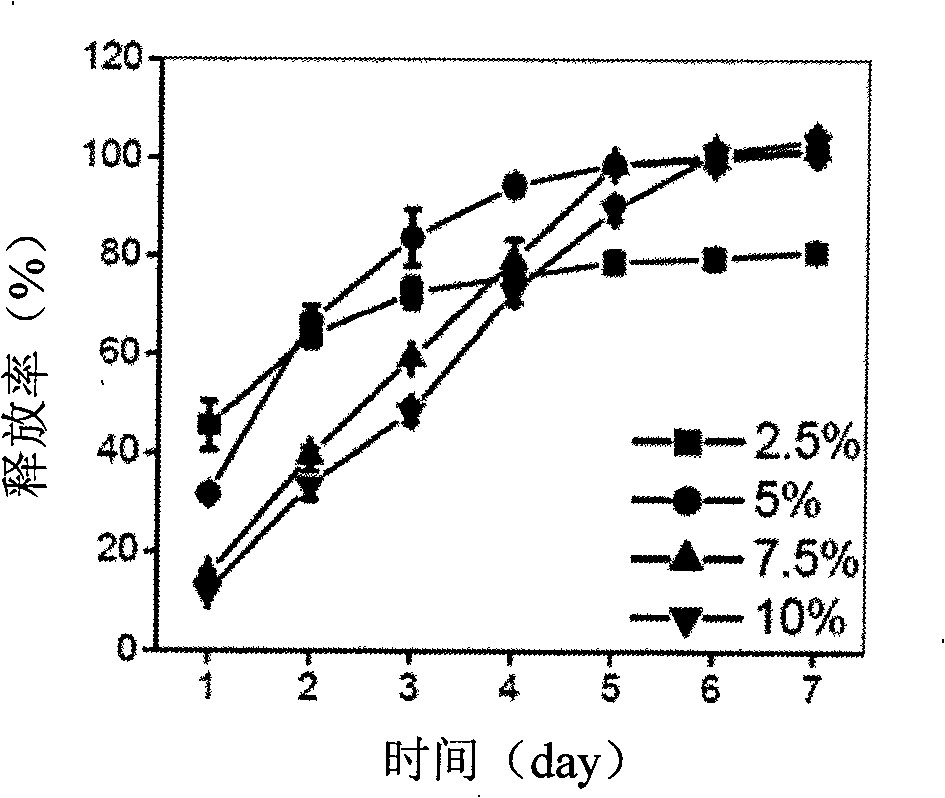

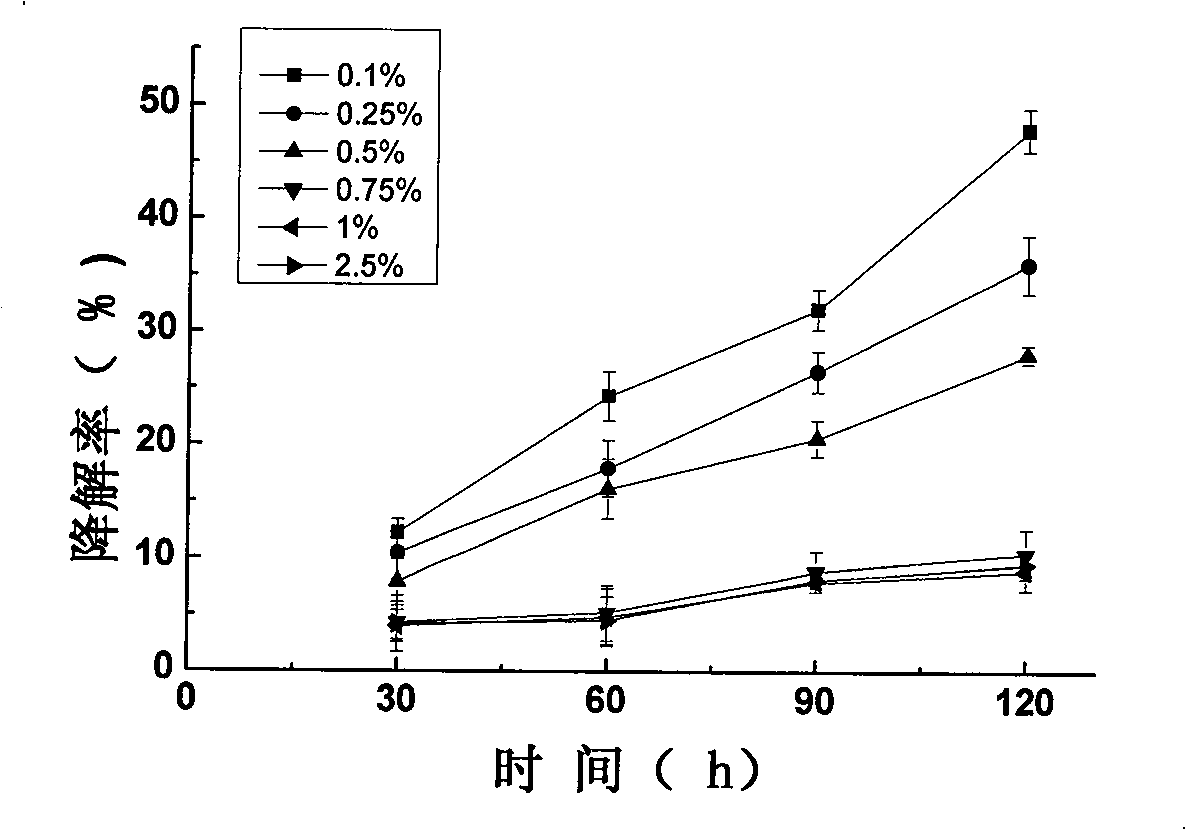

[0028]Embodiment 2: the influence of crosslinking agent concentration on material degradation performance

[0029] Remove the terminal peptide through enzymatic digestion to obtain incomplete collagen without antigenicity, dissolve the collagen swelling solution and chitosan respectively with 0.5M acetic acid, and prepare a collagen solution with a concentration of 0.8% (wt) and a concentration of 0.8% (wt) Chitosan solution, then add silver-loaded inorganic antibacterial agent powder FUMAT T200-4 with zirconium phosphate as carrier in the chitosan solution, so that the content of FUMATT200-4 is 10% (wt). After stirring, ultrasonication, and stirring again, it was fully stirred and mixed with the chitosan solution at a mass ratio of 7:3 to obtain a collagen / chitosan / FUMAT T200-4 dispersion, which was dried to obtain a 10% (wt) FUMATT200 Collagen of -4: the composite film of chitosan=7: 3, cross-linking 12h obtains cross-linking degree in the glutaraldehyde aqueous solution of ...

Embodiment 3

[0030] Example 3: In vitro biological safety evaluation of composite membranes containing different concentrations of antibacterial agents

[0031] Remove the terminal peptide through enzymatic digestion to obtain incomplete collagen without antigenicity, dissolve the collagen swelling solution and chitosan respectively with 0.05M acetic acid, and prepare a collagen solution with a concentration of 0.6% (wt) and a concentration of 0.6% (wt) Chitosan solution, then add silver-loaded inorganic antibacterial agent powder HN-300 with sodium phosphate crystals as the carrier in the chitosan solution, after stirring, ultrasonication, and stirring again, mix with the chitosan solution at a ratio of 9:1 The mass ratio is fully stirred and mixed to obtain the collagen / chitosan / HN-300 dispersion liquid, wherein the content of HN-300 is 10%, 7.5%, 5%, 2.5% (wt), and the prepared dispersion liquid is pressed by 3cm 2 / g Spread the film evenly on a polytetrafluoroethylene plate, and place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com