Antivibration wear resistant paint or shock absorption sound deadening sheet

A technology of wear-resistant paint and muffler sheet, applied in coatings, epoxy resin coatings, etc., can solve the problems of wear resistance, poor impact resistance, low adhesion, easy aging, etc., and achieve good corrosion resistance and workability. good, decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

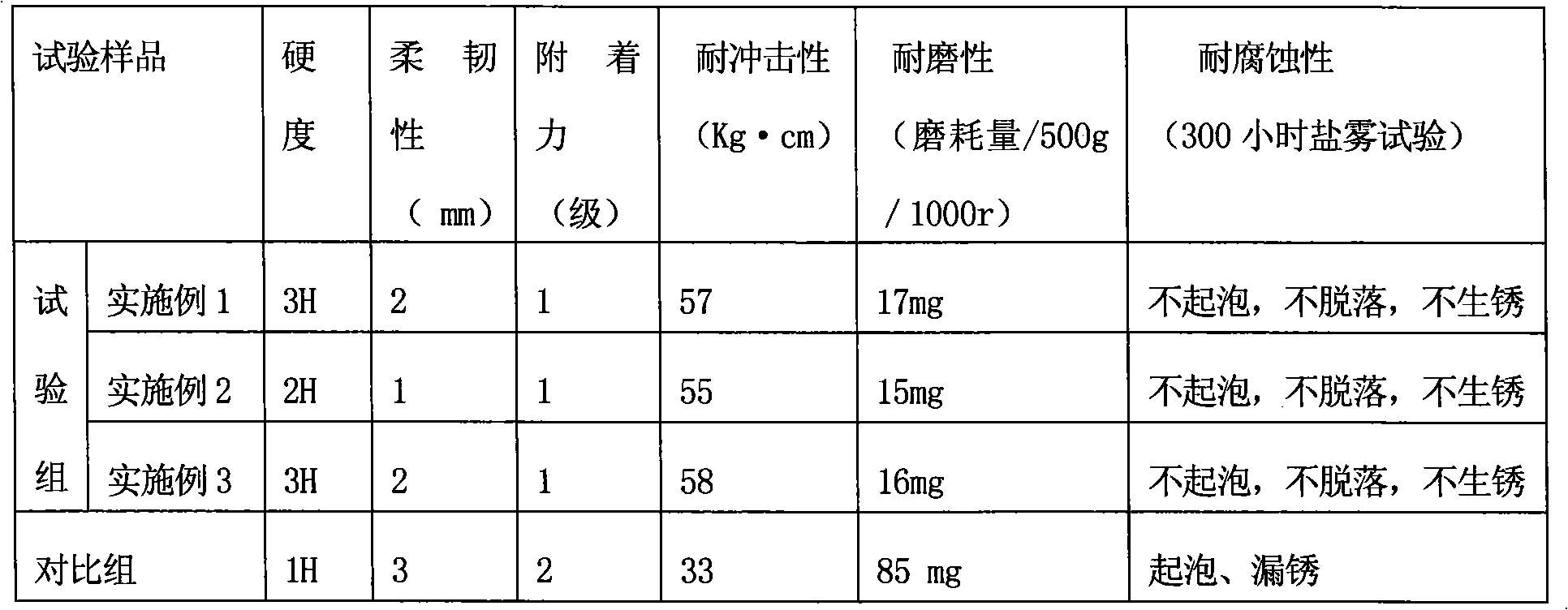

Embodiment 1

[0021] Example 1: Put 1 part (1 part is 50g, the same below) of γ-aminopropyltriethoxysilane in a flask, pour ethyl acetate in the ratio of 1:7 to the silane coupling agent, and then add For 1 part of p-toluenesulfonic acid, then add 7 parts of nanometer silicon dioxide powder and 3 parts of nanometer barium sulfate powder to the ethyl acetate solution of the coupling agent under stirring state, and treat it with ultrasonic vibration for 40 Minutes later, the ethyl acetate was distilled off under reduced pressure and dried to obtain the active nano filler; Mix with 20 parts of xylene, then add 15 parts of cycloaliphatic epoxy resin CER-170 (manufactured by Wuhan Senmao Fine Chemical Co., Ltd.) and active nano-filler, stir evenly, heat up to 110 ° C, and disperse at a constant temperature of 1000 rpm for 30 Minutes, to obtain mixed resin; Then 15 parts of butyl acetate, 8 parts of carbon black, 1.5 parts of cellulose acetate butyrate, 2 parts of octadecyl dimethyl hydroxyethyl ...

Embodiment 2

[0022] Example 2: 2 parts (1 part is 50g, the same below) γ-aminopropyltrimethoxysilane is placed in a flask, poured into ethyl acetate in a ratio of 1:7 with the silane coupling agent, and then add the 1.5 parts of p-toluenesulfonic acid, then add 5 parts of nano-silica powder and 2 parts of nano-barium sulfate powder to the ethyl acetate solution of coupling agent under stirring state, and treat with ultrasonic vibration for 40 minutes Finally, the ethyl acetate was distilled off under reduced pressure and dried to obtain active nanofillers; then in the reaction kettle of the vacuum disperser, first mix 90 parts of thermosetting hydroxyacrylic resin (A900) with 25 parts of xylene, and then add 18 parts of cycloaliphatic epoxy resin CER-170 and active nano-filler, stir evenly, heat up to 115 ° C, and disperse at a constant temperature of 1000 rpm for 30 minutes to obtain a mixed resin; then 24 parts of butyl acetate, 10 parts of carbon black , 2 parts of cellulose acetate but...

Embodiment 3

[0023] Example 3: 1.5 parts (1 part is 50g, the same below) of γ-aminopropyltriethoxysilane is placed in a flask, poured into ethyl acetate at a ratio of 1:7 to the silane coupling agent, and then added For 1.2 parts of p-toluenesulfonic acid, then add 6 parts of nano-silica powder and 2.5 parts of nano-barium sulfate powder to the ethyl acetate solution of the coupling agent under stirring, and treat it with ultrasonic vibration for 40 Minutes later, the ethyl acetate was distilled off under reduced pressure, dried to obtain the active nanofiller; then in the reactor of the vacuum disperser, 100 parts of thermosetting hydroxyacrylic resin (A900) was mixed with 30 parts of xylene, and then Add 20 parts of cycloaliphatic epoxy resin CER-170 and active nano filler, stir evenly, raise the temperature to 120°C, and disperse at a constant temperature of 1000rpm for 30 minutes to obtain a mixed resin; then add 20 parts of butyl acetate, 9 parts of carbon Black, 1.8 parts of cellulos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com