Water-borne environment-friendly base coloring agent

An environment-friendly, colorant technology, applied in the direction of coating, etc., can solve the problems of construction personnel's health and environmental hazards, oily colorant storage time is easy to return to coarseness, precipitation and other problems, to achieve fast drying speed, strong coloring power, and attached focus on good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

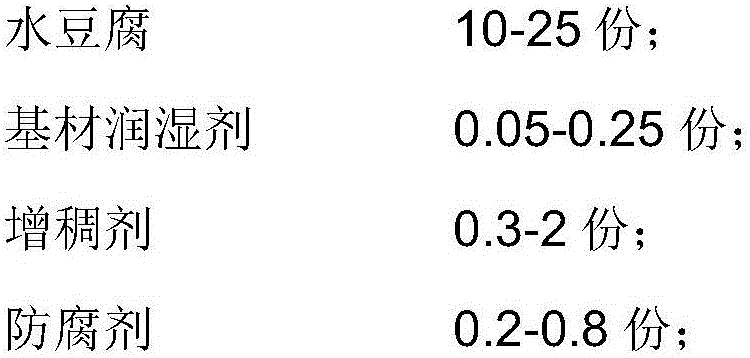

[0023] The water-based environment-friendly bottom coloring agent comprises the following components in parts by weight:

[0024]

[0025] Among them, the thickener is selected from one or more of organic bentonite, fumed silica, polyamide wax, synthetic sheet silicate or synthetic magnesium silicate with sheet structure, used to prevent fillers from sink and increase paint dilution.

[0026] Wherein, the bactericide is selected from one or more of chloromethyl, methylthiazolinone or formaldehyde.

[0027] Among them, the water-based pigment is a general-purpose water-based color paste, which is used for substrate coloring, and its main component is one or two of iron oxide red, iron oxide yellow, phthalocyanine blue or carbon black paste.

[0028] According to the above-mentioned components, an environment-friendly base colorant is prepared.

Embodiment 2

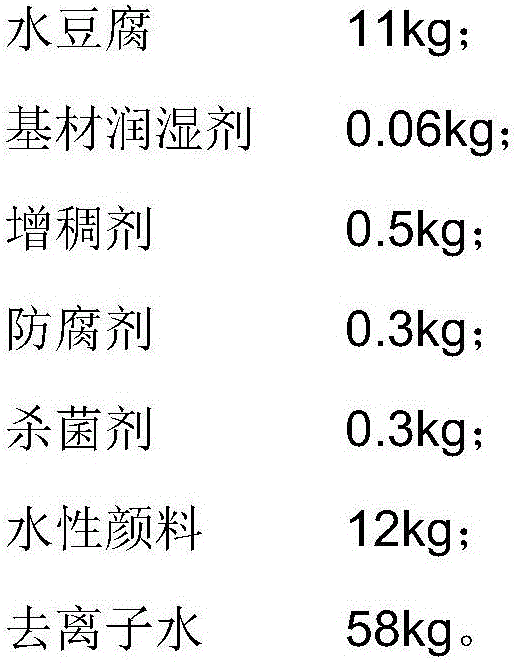

[0030] The water-based environment-friendly bottom coloring agent comprises the following components in parts by weight:

[0031]

[0032] Among them, the thickener is selected from one or more of organic bentonite, fumed silica, polyamide wax, synthetic sheet silicate or synthetic magnesium silicate with sheet structure, used to prevent fillers from sink and increase paint dilution.

[0033] Wherein, the bactericide is selected from one or more of chloromethyl, methylthiazolinone or formaldehyde.

[0034] Among them, the water-based pigment is a general-purpose water-based color paste, which is used for substrate coloring, and its main component is one or two of iron oxide red, iron oxide yellow, phthalocyanine blue or carbon black paste.

[0035] According to the above-mentioned components, an environment-friendly base colorant is prepared.

Embodiment 3

[0037] The water-based environment-friendly bottom coloring agent comprises the following components in parts by weight:

[0038]

[0039] Among them, the thickener is selected from one or more of organic bentonite, fumed silica, polyamide wax, synthetic sheet silicate or synthetic magnesium silicate with sheet structure, used to prevent fillers from sink and increase paint dilution.

[0040] Wherein, the bactericide is selected from one or more of chloromethyl, methylthiazolinone or formaldehyde.

[0041] Among them, the water-based pigment is a general-purpose water-based color paste, which is used for substrate coloring, and its main component is one or two of iron oxide red, iron oxide yellow, phthalocyanine blue or carbon black paste.

[0042] According to the above-mentioned components, an environment-friendly base colorant is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com