Method for smelting very-low carbon and high silicon stainless steel by AOD

A stainless steel and high-silicon technology, applied in the field of metallurgical technology, can solve the problems of low decarburization efficiency, inability to decarburize by blowing oxygen, and low output, and achieve the effects of improving decarbonization efficiency, saving investment, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The situation of a furnace of 00Cr14NI14Si4 steel smelted on 20TAOD is as follows:

[0032] The chemical composition required by the standard (parts by mass percentage)

[0033] C

[0034] Chemical composition of molten steel transferred by electric furnace (mass percentage)

[0035] C

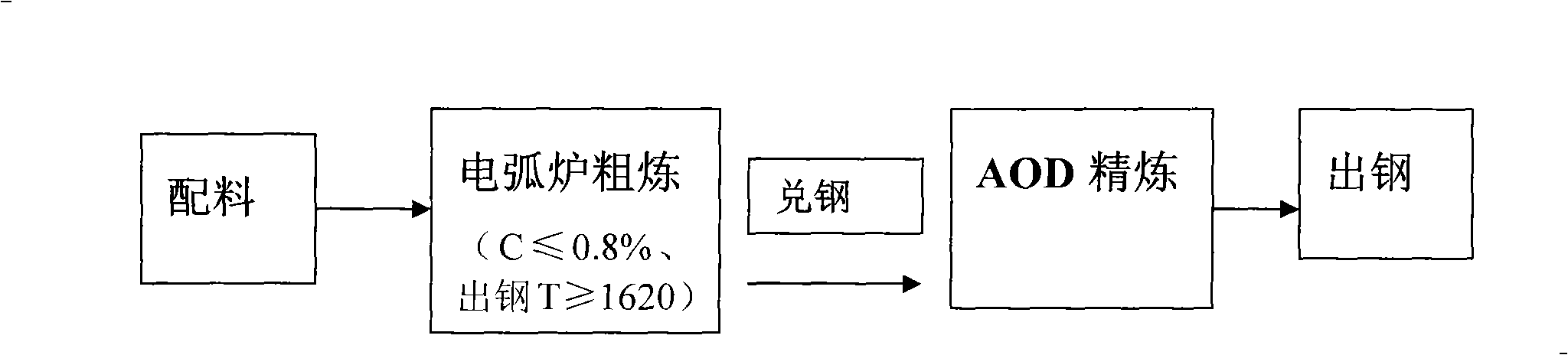

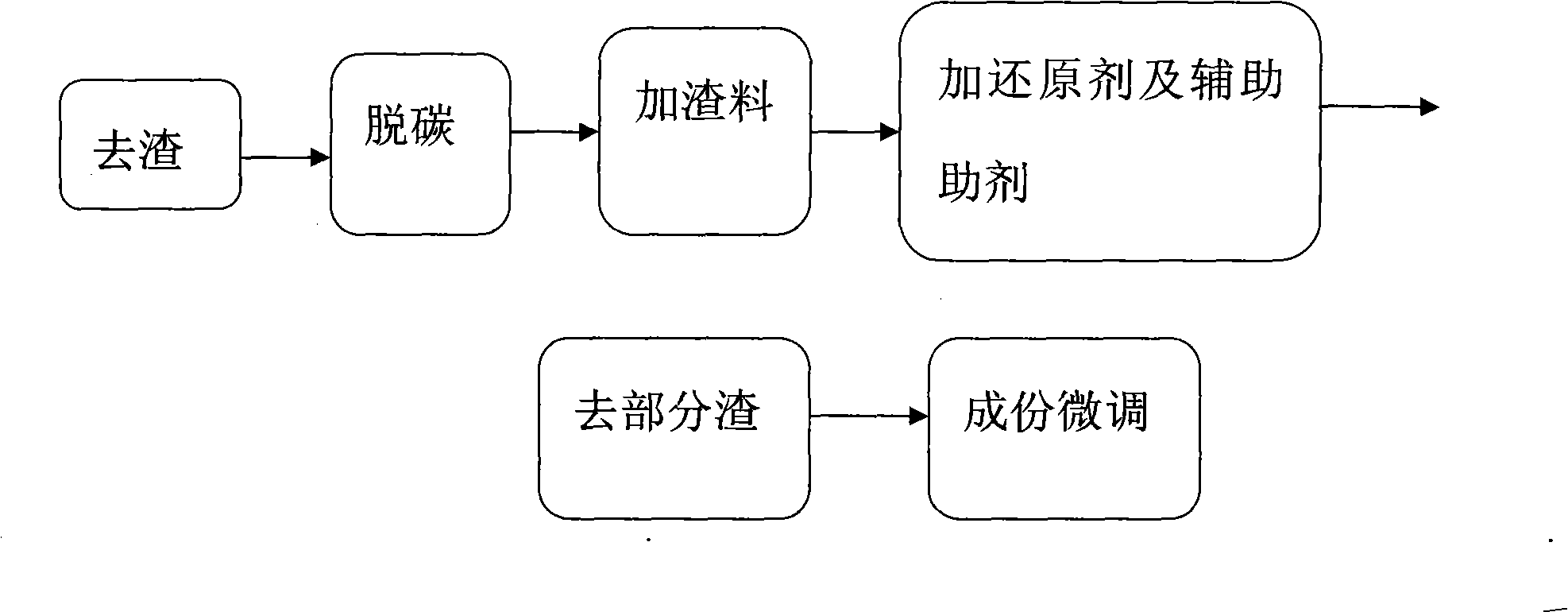

[0036] AOD smelting process

[0037] After the electric furnace is mixed with steel to AOD, the temperature is: 1580°C, the amount of molten steel is 19200Kg, and the chemical composition is as shown in the above table;

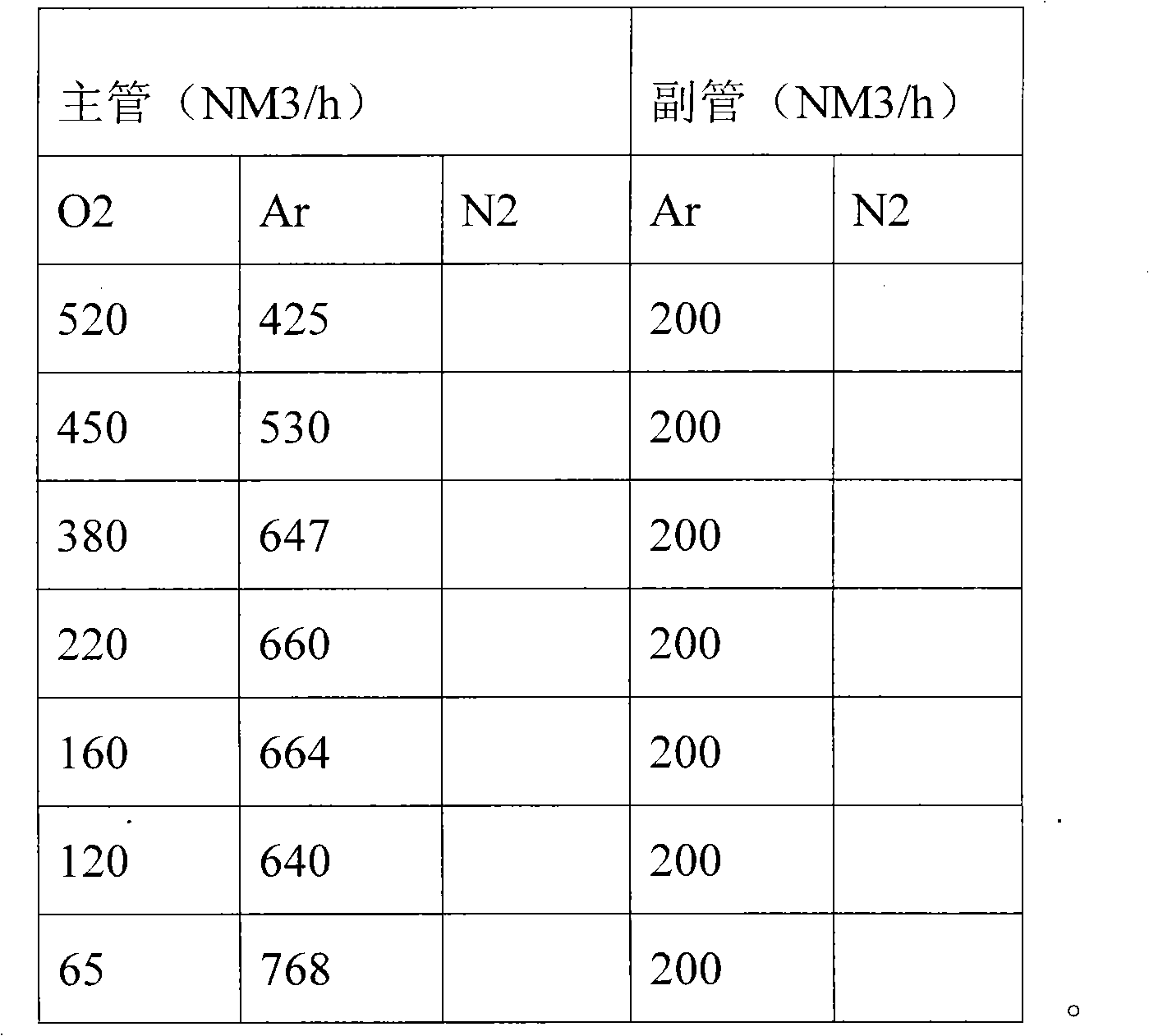

[0038] The first stage of decarburization (the decarburization period when the carbon is greater than 0.20%) has a ratio of oxygen to argon of 4:1, and the flow rate is: O: 1200NM3 / h, Ar: 300NM3 / h (the argon flow rate of the main pipe: 100NM3 / h; the auxiliary pipe Argon flow: 200NM3 / h) Add metallurgical lime, alloy high carbon ferrochrome, pure nickel block, magnesia.

[0039] When the temperature of AOD molten steel reaches nearly 1700°C, me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com