Process for industrially producing high quality aromatic polycarbonate

A polycarbonate and aromatic technology, applied in the field of high-quality and high-performance aromatic polycarbonate, can solve problems such as difficult separation, no record hint, no disclosure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0377] (1) Continuously prepare the operation (I) of diphenyl carbonate

[0378]

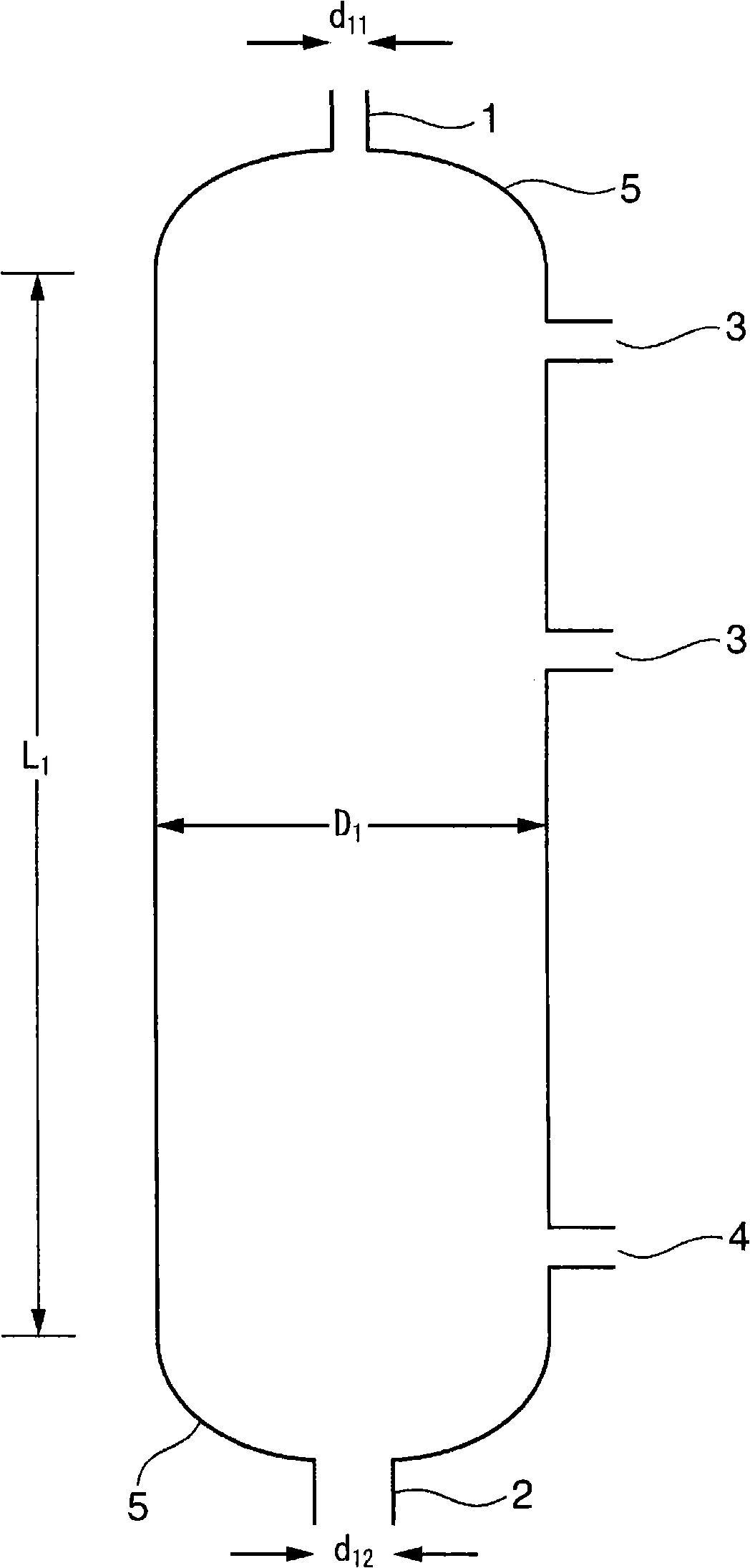

[0379] use figure 1 L as shown 1 =3300cm, D 1 =500cm, L 1 / D 1 =6.6,n 1 =80,D 1 / d 11 =17,D 1 / d 12 =9 continuous multistage distillation columns. In addition, in this embodiment, as an inner part, a cross-sectional area of each hole = about 1.5 cm 2 , with the number of holes = about 250 / m 2 perforated trays.

[0380]

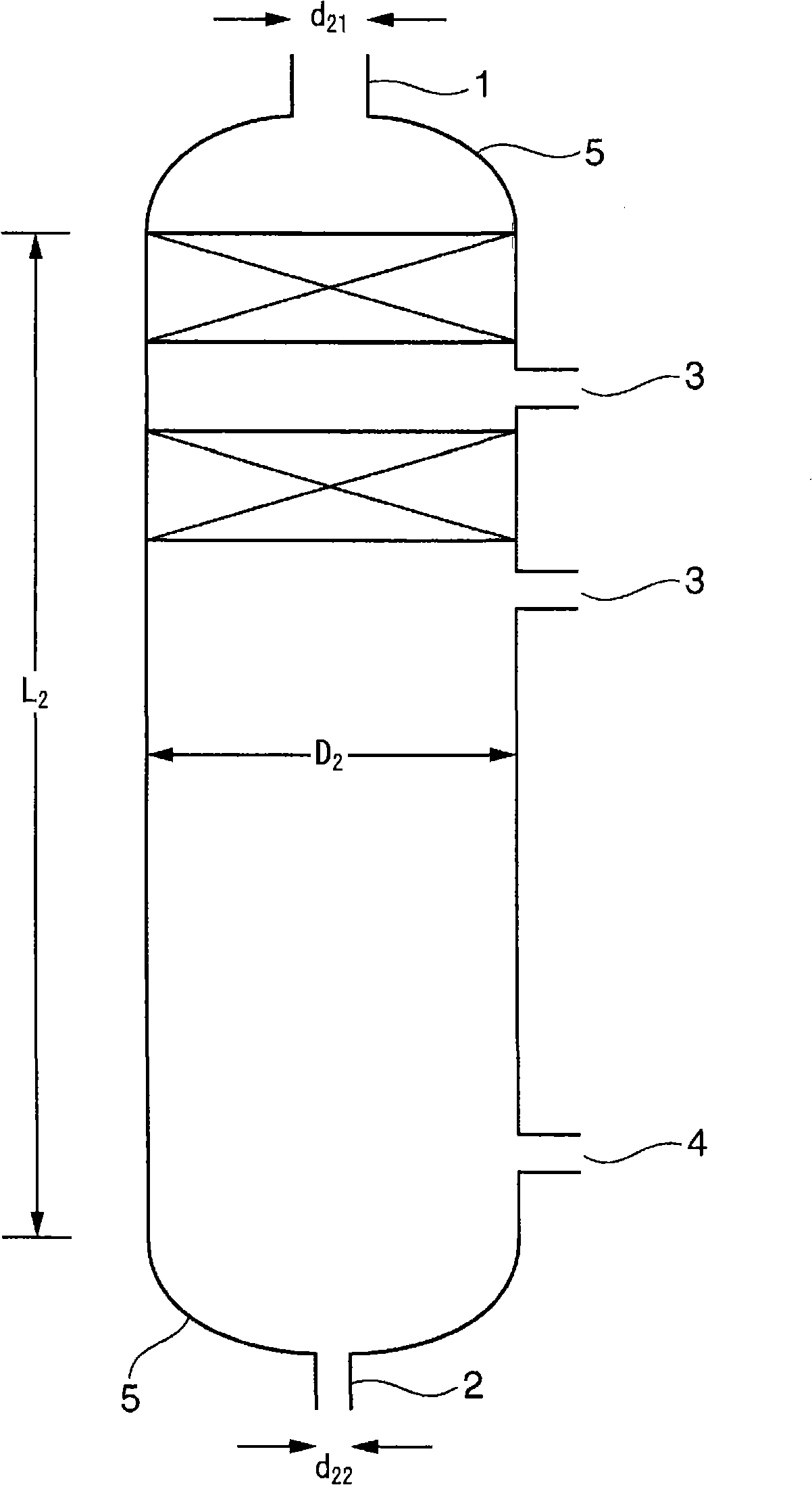

[0381] use figure 2 L as shown 2 =3100cm, D 2 =500cm, L 2 / D 2 =6.2,n 2 =30,D 2 / d 21 =3.85,D 2 / d 22 =11.1 continuous multistage distillation column. In addition, in this embodiment, as internal parts, 2 Mellapaks (a total of 11 theoretical stages) are installed in the upper part, and the cross-sectional area of each hole = about 1.3 cm is used in the lower part. 2 , with the number of holes = about 250 / m 2 perforated trays.

[0382]

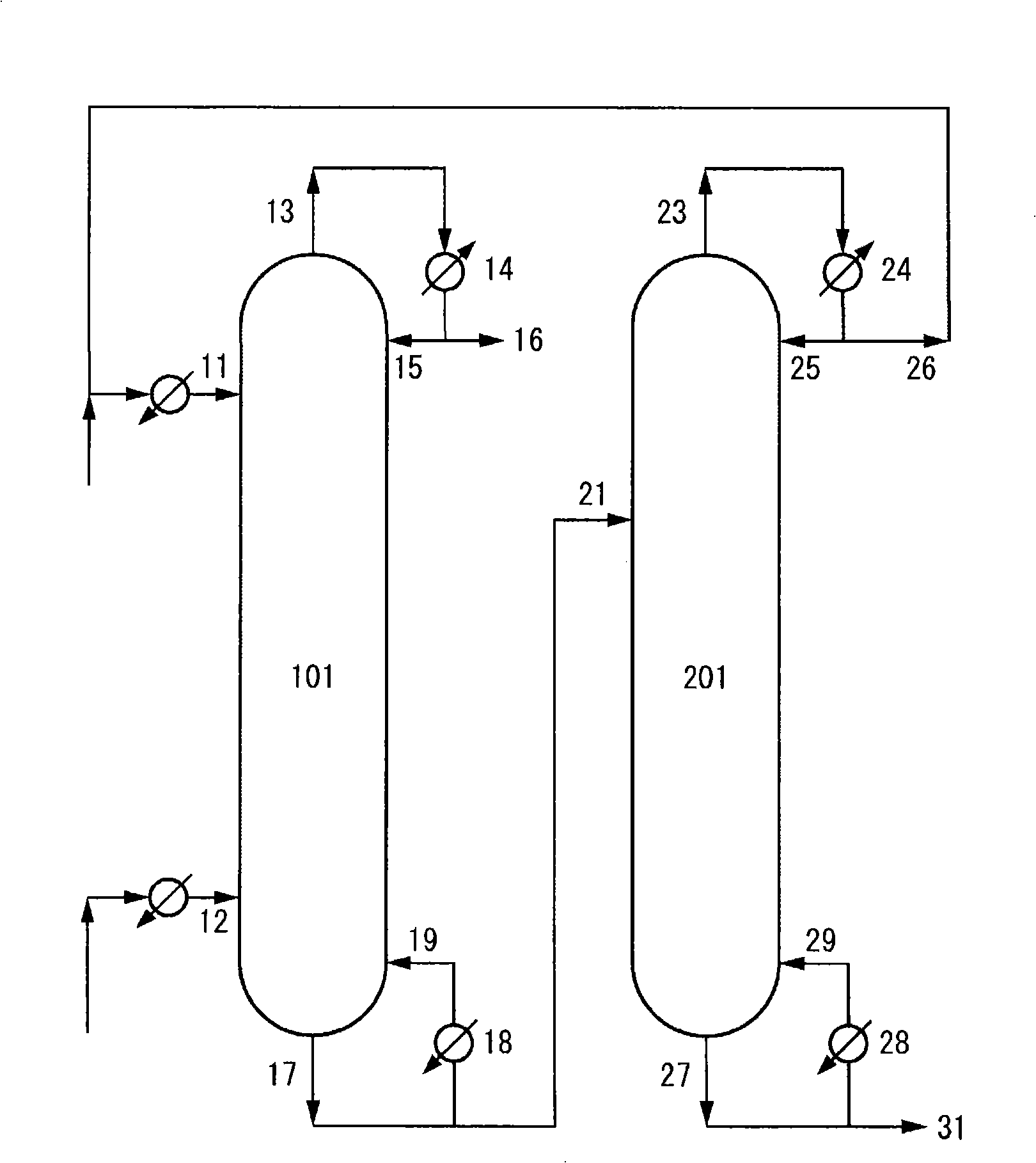

[0383] use image 3 The first continuous multistage distillation column 101 as shown and the second contin...

Embodiment 2

[0409] (1) Continuously prepare the operation (I) of diphenyl carbonate

[0410] Using the same apparatus as in Example 1, reactive distillation was performed under the following conditions.

[0411] The raw material 1 containing phenol / dimethyl carbonate = 1.1 (weight ratio) was continuously introduced in a liquid state at a flow rate of 40 tons / hour from the upper inlet 11 of the first continuous multistage distillation column 101 . On the other hand, the raw material 2 containing dimethyl carbonate / phenol=3.9 (weight ratio) was continuously introduced in a gaseous state at a flow rate of 43 tons / hour from the lower introduction port 12 of the first continuous multistage distillation column 101. The molar ratio of the raw materials introduced into the first continuous multistage distillation column 101 is dimethyl carbonate / phenol=1.87. This raw material does not substantially contain halogen (beyond the detection limit of ion chromatography, 1 ppb or less). Catalyst accor...

Embodiment 3

[0422] The cross-sectional area of each hole of the perforated tray in the second continuous multistage distillation column 201 = about 1.8 cm 2 , except that, using the same apparatus as in Example 1, reactive distillation was carried out under the following conditions.

[0423] The raw material 1 containing phenol / dimethyl carbonate = 1.7 (weight ratio) was continuously introduced in a liquid state at a flow rate of 86 tons / hour from the upper introduction port 11 of the first continuous multistage distillation column 101 . On the other hand, the raw material 2 containing dimethyl carbonate / phenol = 3.5 (weight ratio) was continuously introduced in a gaseous state at a flow rate of 90 tons / hour from the lower introduction port 12 of the first continuous multistage distillation column 101 . The molar ratio of the raw materials introduced into the first continuous multistage distillation column 101 is dimethyl carbonate / phenol=1.44. This raw material does not substantially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com