Method of preparing type p ZnO nano-wire

A nanowire and p-type technology, which is applied in the field of preparation of p-type ZnO nanowires, can solve the problems of high vapor pressure and difficulty in obtaining p-type ZnO nanowires, and achieve the effect of overcoming the difficulty of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Growth of p-type ZnO nanowire arrays with a diameter of about 100 nm

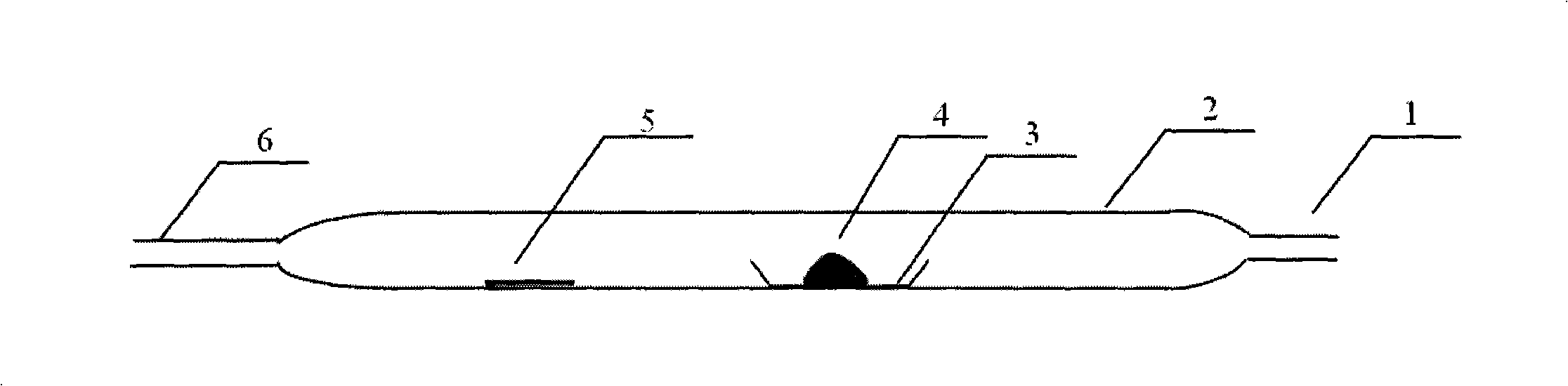

[0022] (1) After weighing the powder of high-purity zinc powder and gallium arsenide according to the mass ratio of 6 / 1, put it into a quartz crucible, and put it into the quartz tube of the chemical vapor deposition system together with the cleaned silicon substrate.

[0023] (2) Vacuumize the quartz tube to below 1000 Pa, when the temperature is heated to 650° C., feed oxygen at a flow rate of 100 ml / min, and start the growth of nanowires for 30 minutes.

[0024] (3) After the growth is completed, turn off the oxygen, turn off the heating power, and slowly cool down to below 100°C to take out the sample.

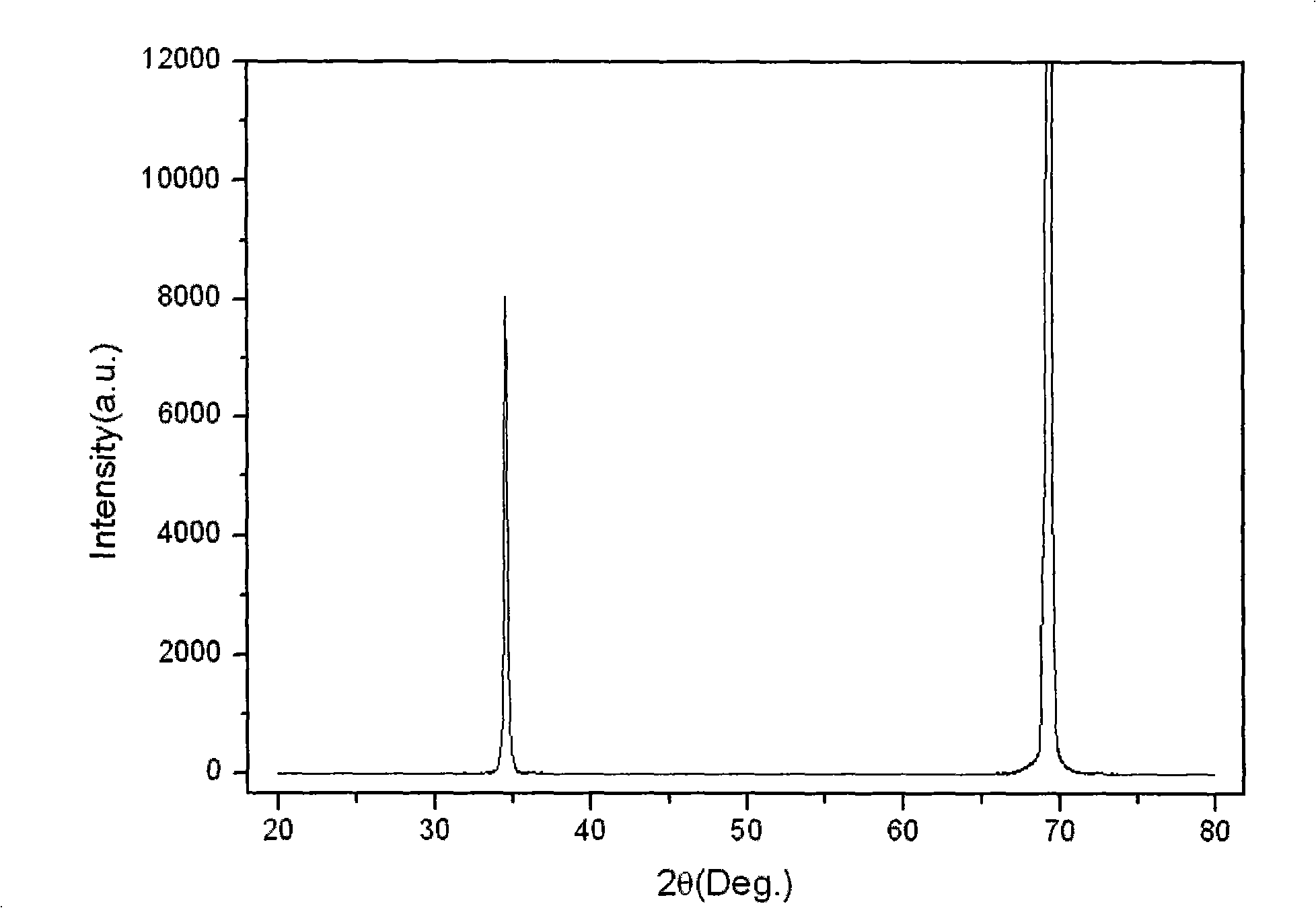

[0025] Utilizing the invention, a p-type ZnO nanowire with a diameter of about 100nm is prepared. X-ray diffraction spectrum shows, only ZnO (002) diffraction peak appears, shows that the As-doped p-type ZnO nanowire that the inventive method makes has good crystalline quality, scanning electron...

Embodiment 2

[0027] Growth of p-type ZnO nanowire arrays with a diameter of about 50 nm

[0028] (1) After weighing the powder of high-purity zinc powder and gallium arsenide according to the mass ratio of 6 / 1, put it into a quartz crucible, and put it into the quartz tube of the chemical vapor deposition system together with the cleaned substrate.

[0029] (3) Vacuumize the quartz tube to below 1000 Pa. When the temperature is heated to 700° C., feed oxygen at a flow rate of 300 ml / min to start the growth of nanowires for 30 minutes.

[0030] (3) After the growth is completed, turn off the oxygen, turn off the heating power, and slowly cool down to below 100°C to take out the sample.

[0031] Utilizing the invention, a p-type ZnO nanowire with a diameter of about 50nm is prepared. X-ray diffraction spectrum shows that the As-doped p-type ZnO nanowires prepared by the inventive method have good crystalline quality, and scanning electron microscopy shows that the prepared ZnO nanowires hav...

Embodiment 3

[0033] The steps of this embodiment and embodiment 1 and embodiment 2 are generally the same, the difference is that zinc arsenide and high-purity zinc powder are used as evaporation sources in the growth process, and other growth conditions are almost the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com