A large-aperture liquid crystal lens array using a composite dielectric layer

A liquid crystal lens array and dielectric layer technology, which can be applied to instruments, nonlinear optics, optics, etc., can solve the problems of complex technology and difficult process, and achieve the effects of simple lens structure, good matching and reduced process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

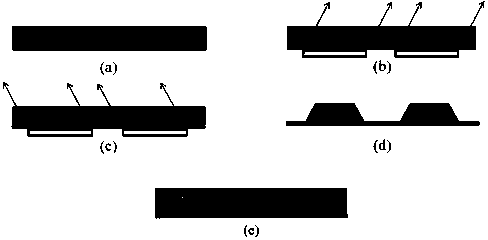

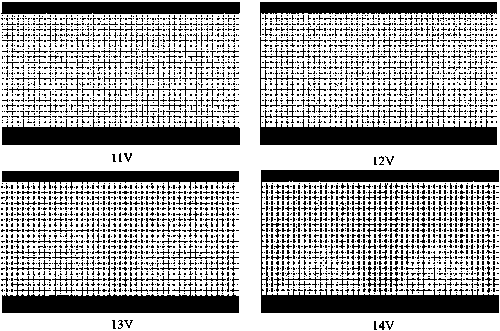

[0019] The present invention proposes a large-aperture liquid crystal lens array using a composite dielectric layer such as figure 1 As shown, the structure from top to bottom is: upper substrate 1, common electrode 2, upper dielectric layer 3, liquid crystal layer 4, high dielectric layer 5, raised material layer 6, pixel electrode 7, lower substrate 8, Composite dielectric layer 9 .

[0020] Composite dielectric layer manufacturing method among the present invention is as figure 2 Shown: 1. The ITO glass substrate is spin-coated with a raised material layer and pre-baked; 2. The spin-coated ITO glass substrate is placed on the mask plate and irradiated obliquely with an ultraviolet lamp; 3. The mask plate and The ITO glass substrate is rotated together by an azimuth angle and then irradiated with an oblique ultraviolet lamp. The oblique irradiation of the ultraviolet lamp needs to be performed several times, and the azimuth angle of each rotation is the same, until the azi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com