P -type delafossite base oxide ozone gas sensory semiconductor material and method for making same

An iron ore-based, oxide-based technology, applied in semiconductor/solid-state device manufacturing, material resistance, electrical components, etc., can solve the problems of inconvenient use and outdoor carrying measurement, short life, high power consumption, etc., and achieve good sensitivity, Good selectivity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

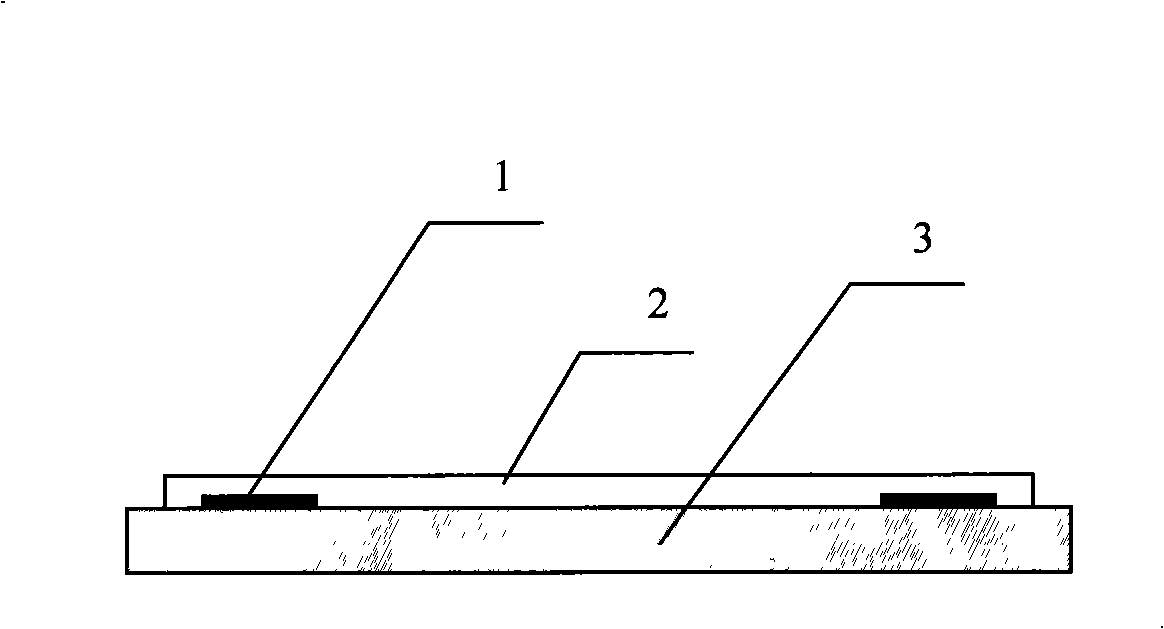

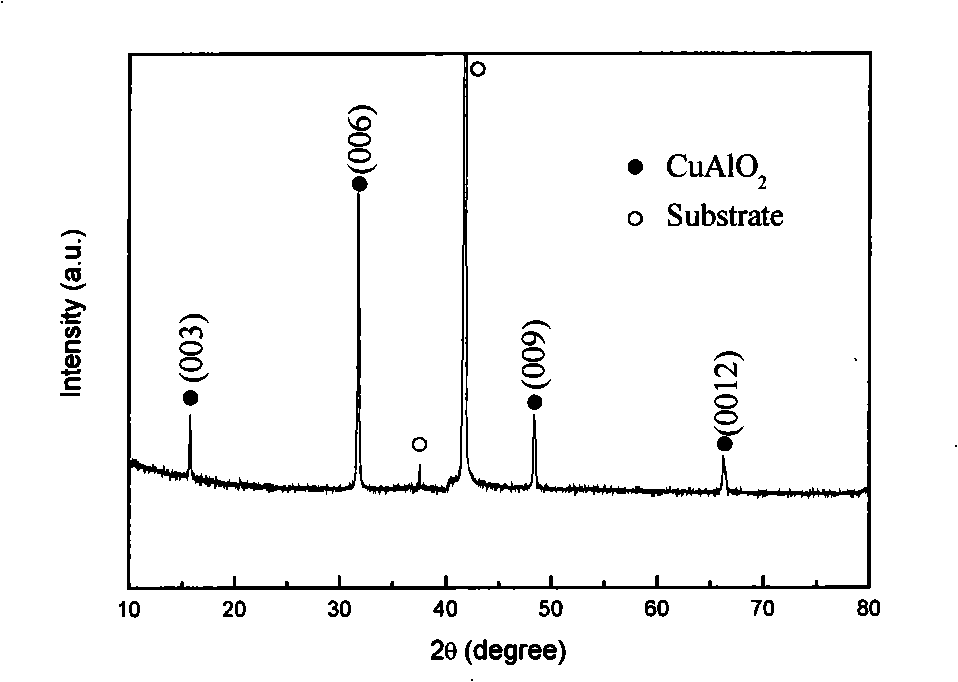

[0019] The oxides of Cu and Al are mixed according to the molar ratio of Cu:Al=1:1, and ground evenly, and the mixture is calcined at 1100°C-1200°C for 20 hours or more to form a gas-sensitive material. Add the gas-sensitive material to the binder and grind it fully to make a slurry coated on Al with gold electrodes and rhodium-platinum leads 2 o 3 on a ceramic substrate. Insulate at an appropriate temperature (at 300°C to 600°C for 2 hours or more) and fire to form a thick-film ozone sensor. The element is very sensitive to ozone at room temperature while exhibiting good selectivity and stability.

Embodiment 2

[0021] The oxides of Cu and Cr are mixed according to the molar ratio of Cu:Cr=1:1, and the ozone gas sensor is made according to the operation procedure of Example 1. The room temperature conductivity of the element is obviously lower than that of the element in Example 1, but the room temperature ozone sensitivity is obviously improved.

Embodiment 3

[0023] The oxides of Cu, Cr and Mg are mixed according to the molar ratio of Cu: Cr=1:0.97:0.03, and the ozone gas sensor is made according to the operation procedure of Example 1. The room temperature ozone sensitivity of the element is equivalent to that of the element in Example 2, but the room temperature conductivity is significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com