Shock resistant compound material and preparation thereof

A composite material and impact-resistant technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of poor impact resistance and welding performance, noise pollution, cost increase, etc., to improve impact resistance, cushioning Material impact, convenient installation and welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

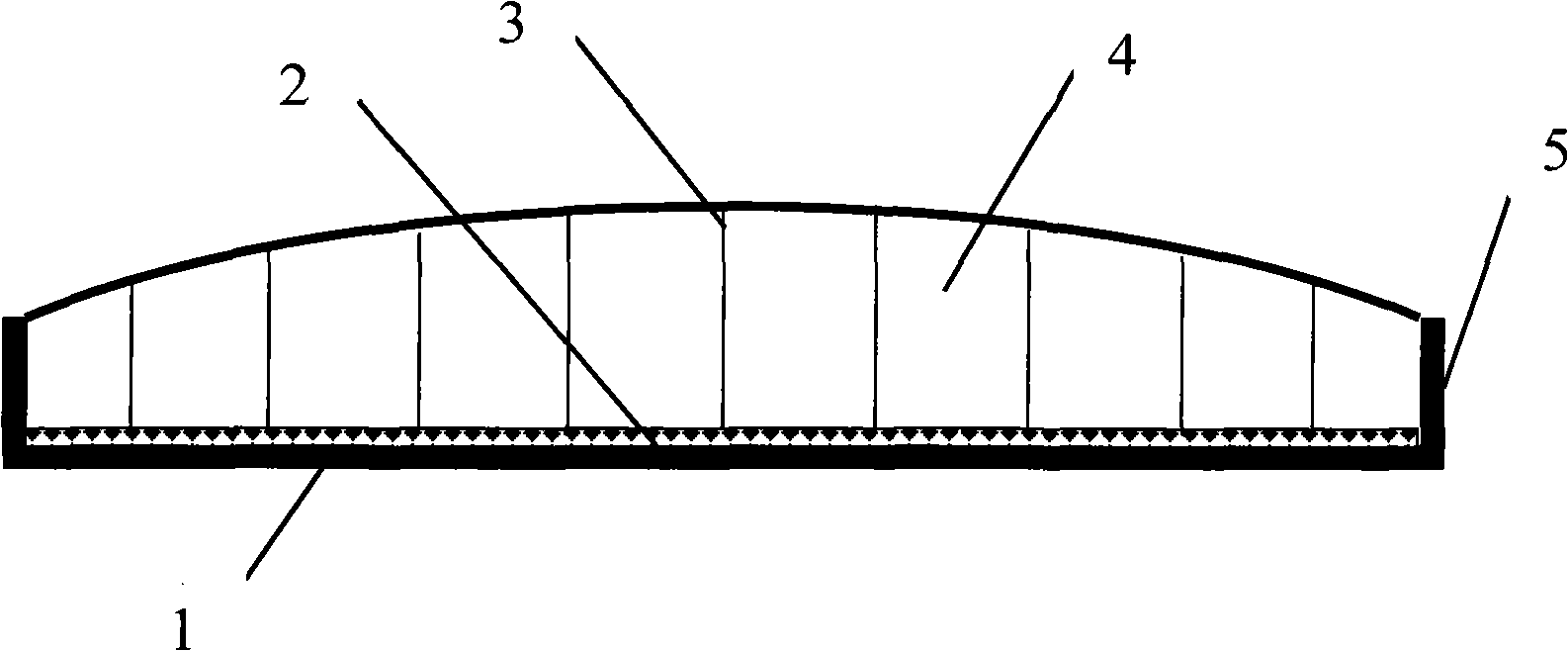

[0030] The preparation method of composite material of the present invention is described as follows:

[0031] Step 1, casting or welding the steel base layer. When the casting method is used, the steel base layer can be made of ordinary carbon steel, and the ingredients can refer to Table 1, and the general casting technology can be used.

[0032] Step 2, casting a high chromium alloy wear-resistant layer. The high chromium alloy wear-resistant layer can be made of high chromium alloy cast iron material and cast into a high chromium alloy cast iron grid block. The specific method is as follows:

[0033] (1) Dosing according to the ingredient requirements in Table 2;

[0034] (2) According to the size division of high chromium alloy cast iron grid blocks, design and process molds and shapes (sand molds);

[0035] (3) Smelting according to the ingredients in (1), reaching the temperature of 1480-1520°C before being released from the furnace, and pouring the molten iron into ...

Embodiment 1

[0040] Composites for impact wear resistance in inclined impact plates in coal production.

[0041] Step 1, casting or welding the steel base layer. In this embodiment, the casting method is adopted, and the steel base layer is made of ordinary carbon steel material, and the ingredients are referred to in Table 1, and the general casting technology is adopted.

[0042] Step 2, casting a high chromium alloy wear-resistant layer. The high chromium alloy wear-resistant layer can be made of high chromium alloy cast iron material and cast into a high chromium alloy cast iron grid block. The specific method is as follows:

[0043] (1) Dosing according to the ingredient requirements in Table 2, the determined final ingredients are (wt%): 2.8% C, 0.8% Mn, 0.8% Si, P≤0.03%, S≤0.03%, 29.0% Cr, 0.8% Mo, 1.0% Cu, 0.2% B, and the rest of Fe, among which P and S are impurities, are controlled below 0.03% respectively.

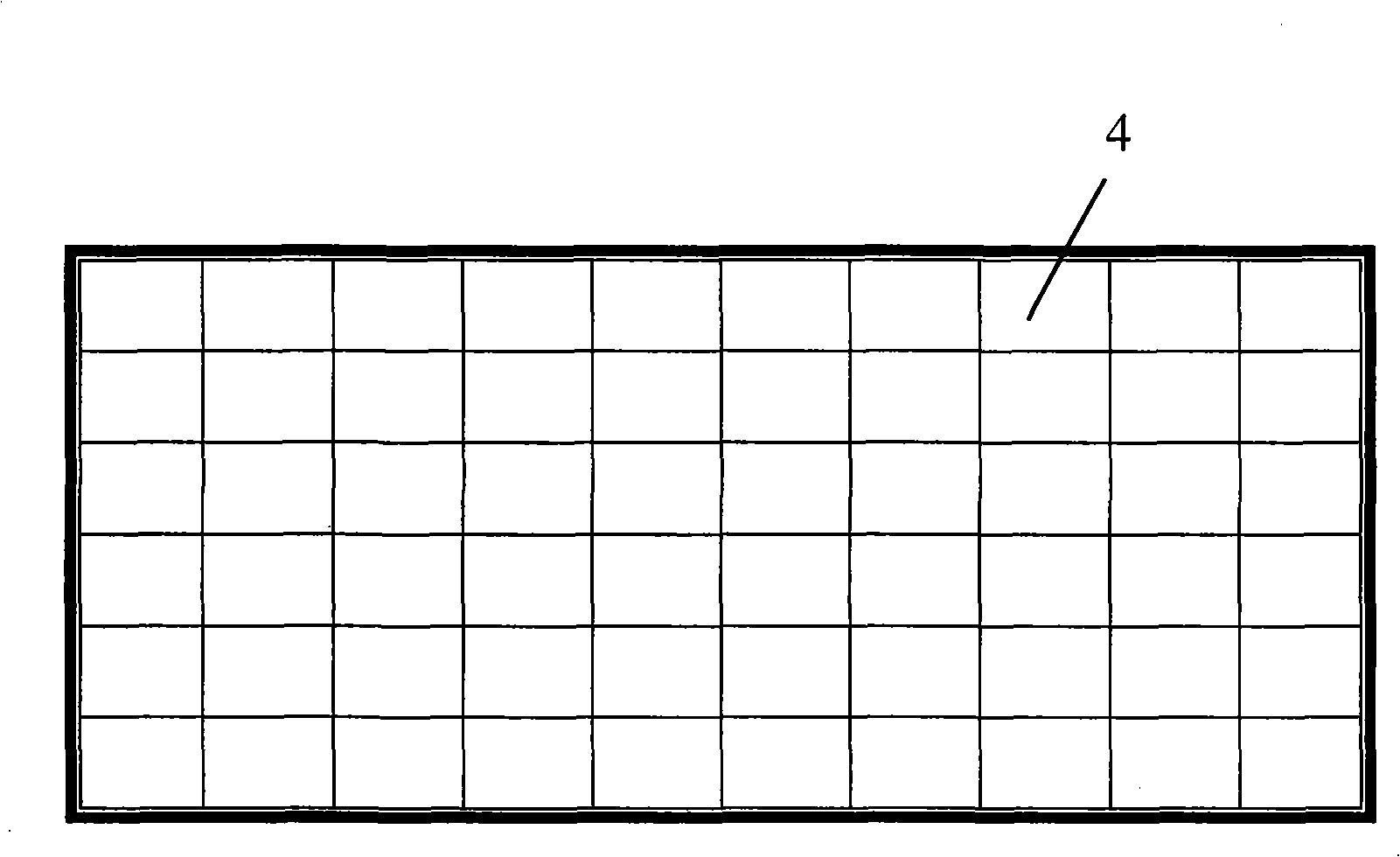

[0044] (2) According to the size division of the high chromium alloy...

Embodiment 2

[0051] Composite materials for impact wear resistance in the preparation of horizontal impact plates in the production of mineral aggregates

[0052] Step 1, casting or welding the steel base layer. The present embodiment 10mm steel plate is welded.

[0053] Step 2, casting a high chromium alloy wear-resistant layer. The high chromium alloy wear-resistant layer can be made of high chromium alloy cast iron material and cast into a high chromium alloy cast iron grid block. The specific method is as follows:

[0054] (1) Dosing according to the ingredient requirements in Table 2, the determined final ingredients are (wt%): 2.9% C, 0.6% Mn, 0.6% Si, P≤0.03%, S≤0.03%, 28.0% Cr, 0.6% Mo, 0.8% Cu, 0.3% B, and the rest are Fe, among which P and S are impurities, which are controlled below 0.03% respectively.

[0055] (2) According to the size division of high chromium alloy cast iron grid blocks, design and process molds and moldings (sand molds); the size of grid block 4 is 120mm×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com