Sintered body and die for hot extrusion molding each using such sintered body

A sintered body, hot extrusion technology, applied in metal extrusion dies, metal extrusion forming tools, metal extrusion and other directions, can solve the problem of high sliding characteristics, high strength, and damage size of extruded material 6, etc. problems, to achieve the effects of suppressing damage and dimensional problems, improving continuous molding time, and improving oxidation prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

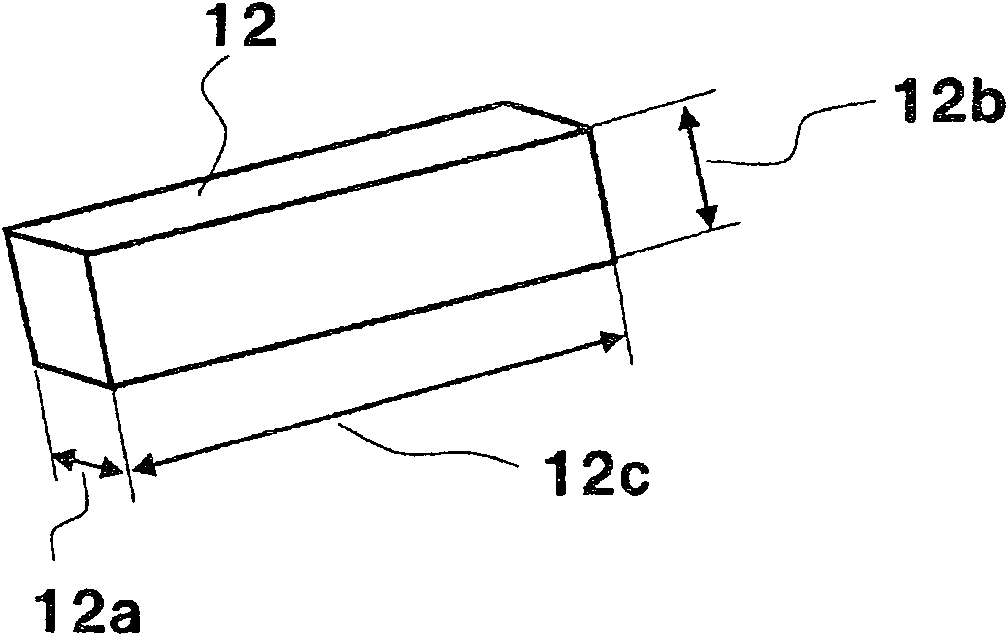

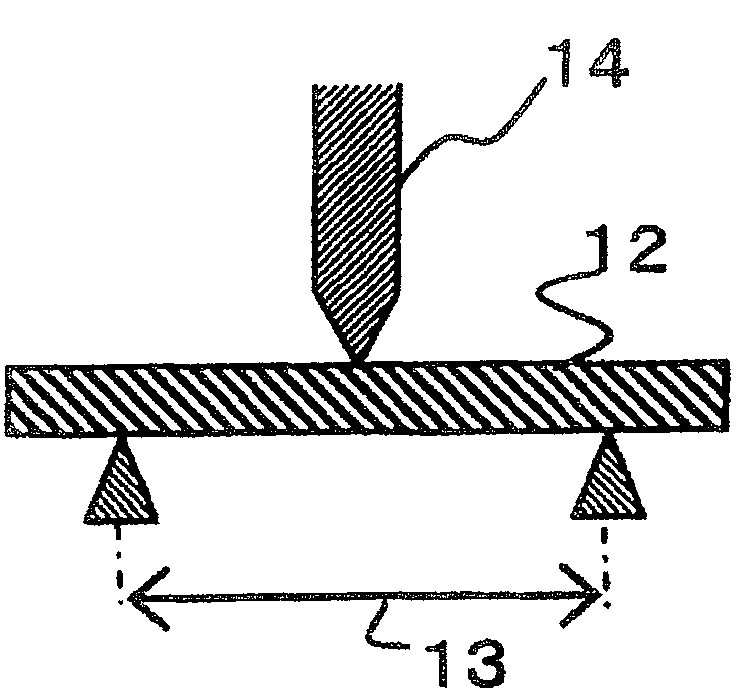

[0084] Each powder was divided into six levels of content to prepare a sintered body made of TiCN-based cermet as a base material of the hot extrusion molding die 1 of the present invention. The TiCN powder is mixed with the fine TiCN powder with an average particle size of 0.5 μm and the coarse TiCN powder with an average particle size of 1.7 μm at a ratio of 8:2 in a specified amount, and the balance is a specified amount of TiCN with an average particle size of 1.2 μm. TaC powder, 1.6μm Ni powder and 1.4μm Cr powder are put into a ball mill made of SUS, so that the crushing ball made of SUS with a size of 2Φ5 is equivalent to the same capacity of the total powder, plus twice the volume Volume of ethanol and 3% paraffin wax based on the total powder mass ratio were pulverized and mixed for 48 hours (hr) to prepare a slurry.

[0085] Here, when the total content of the aforementioned TiCN, TaC, Ni, and Cr is taken as 100% by mass, the respective contents are TiCN=63% by mass,...

Embodiment 2

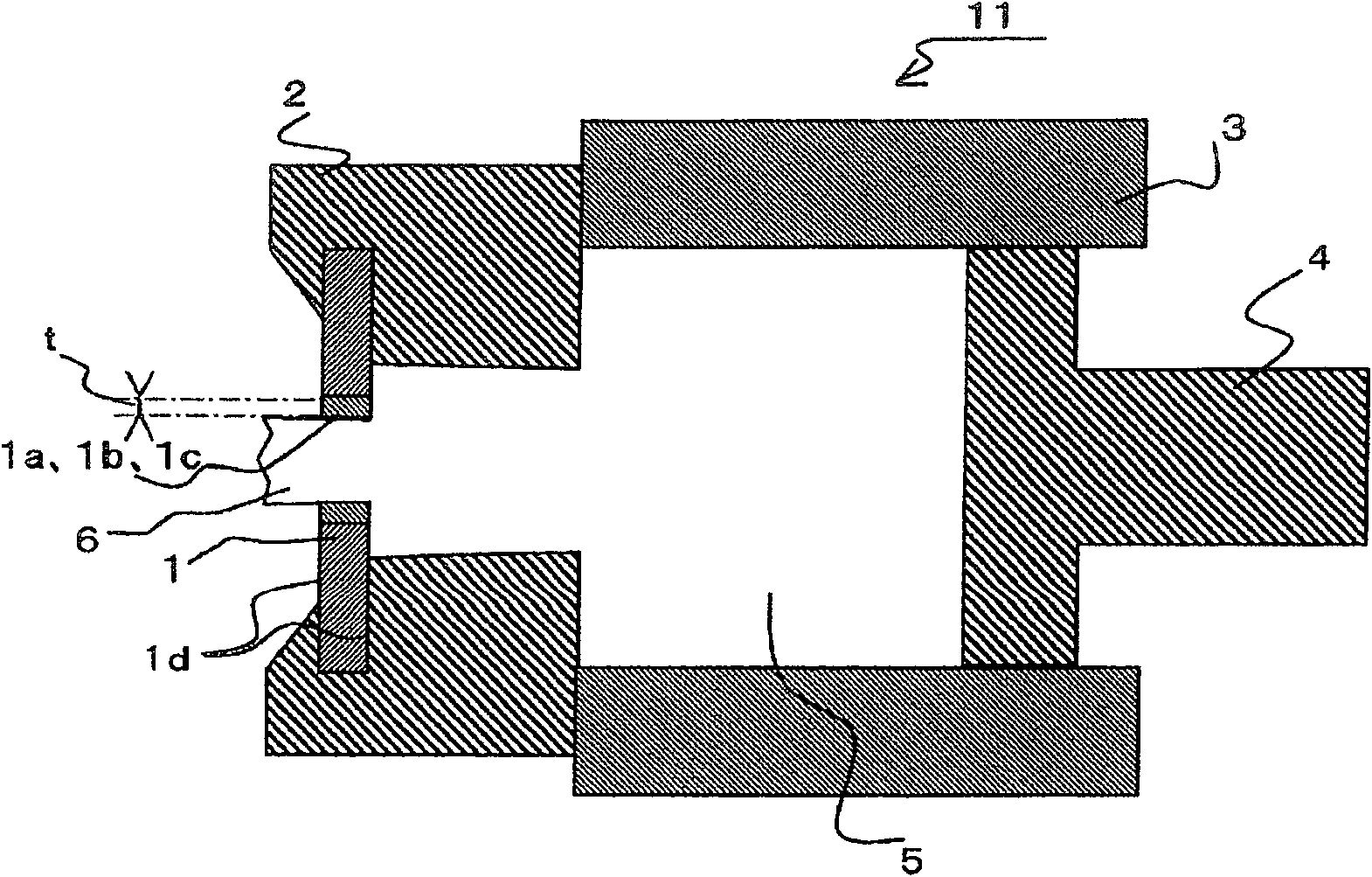

[0111] make Figure 4 The hot extrusion molding dies 1 and 101 shown in (a) and (b) were mounted on hot extrusion molding apparatuses 11 and 111 for hot extrusion molding, and the hot extrusion molding dies 1 and 101 were evaluated. What used the sintered bodies of sample Nos. 1-3 of Example 1 to make the die 1 for hot extrusion molding was sample No. 11-13 of the embodiment of the present invention, and used sample No. 4, The sintered bodies of 6 are sample Nos. 14 and 15 outside the scope of the present invention.

[0112] As a comparative example, the material of the hot extrusion molding die 101 is made of ZrO 2 : 94% by mass, Y 2 o 3 : Zirconium ceramics composed of 6% by mass, this is sample No.16.

[0113] Also, as a comparative example, such as Figure 5 As shown, the main body of the hot extrusion molding die 101 is SKD61, and the inner peripheral surface 101b of the through hole 101a is made of NiCr / Cr 3 C 2 The cermet material composed of / NbC forms the reinfo...

Embodiment 3

[0130] When the inner peripheral surface 1b of the through-hole 1a of the hot extrusion molding die 1 of the present invention is formed with and without the amorphous film 1c, and when the amorphous film 1c is alumina or silicon carbide, it is further confirmed that its production thickness t is In the case of the range of 0.1 to 1.5 μm, the effect on the continuous molding time in a high temperature environment.

[0131] The sintered body constituting the die 1 for hot extrusion molding had the same composition and shape as Sample No. 12 of Example 2. Then, if figure 1 As shown, an amorphous film 1c of aluminum oxide and silicon carbide is formed on the inner peripheral surface 1b of the through-hole 1a to have a thickness t of six levels of 0.1, 0.2, 0.5, 1.0, 1.2, and 1.5 μm, and one film is produced for each And install it on the hot extrusion forming device 11, after carrying out preliminary heating for 1 hr, implement continuous forming to the extruded material 6 of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com