Special die for producing windowpane run channel sealing strip

A technology for automotive glass and sealing strips, which is applied to sealing devices, engine sealing, vehicle components, etc., can solve the problems of unreasonable structure, poor sealing performance, large sliding resistance, etc., and achieves simple processing technology, good sealing performance, Low sliding resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

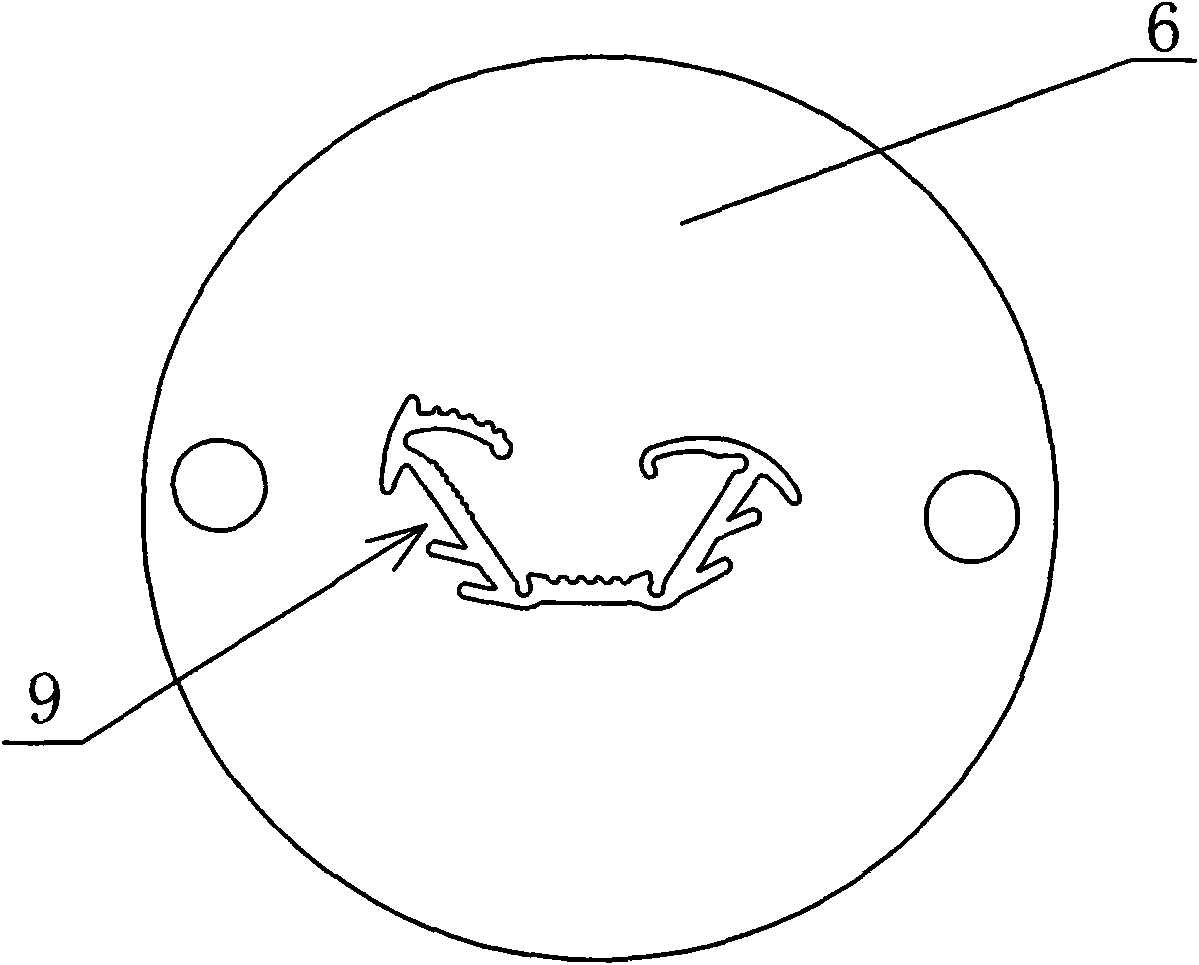

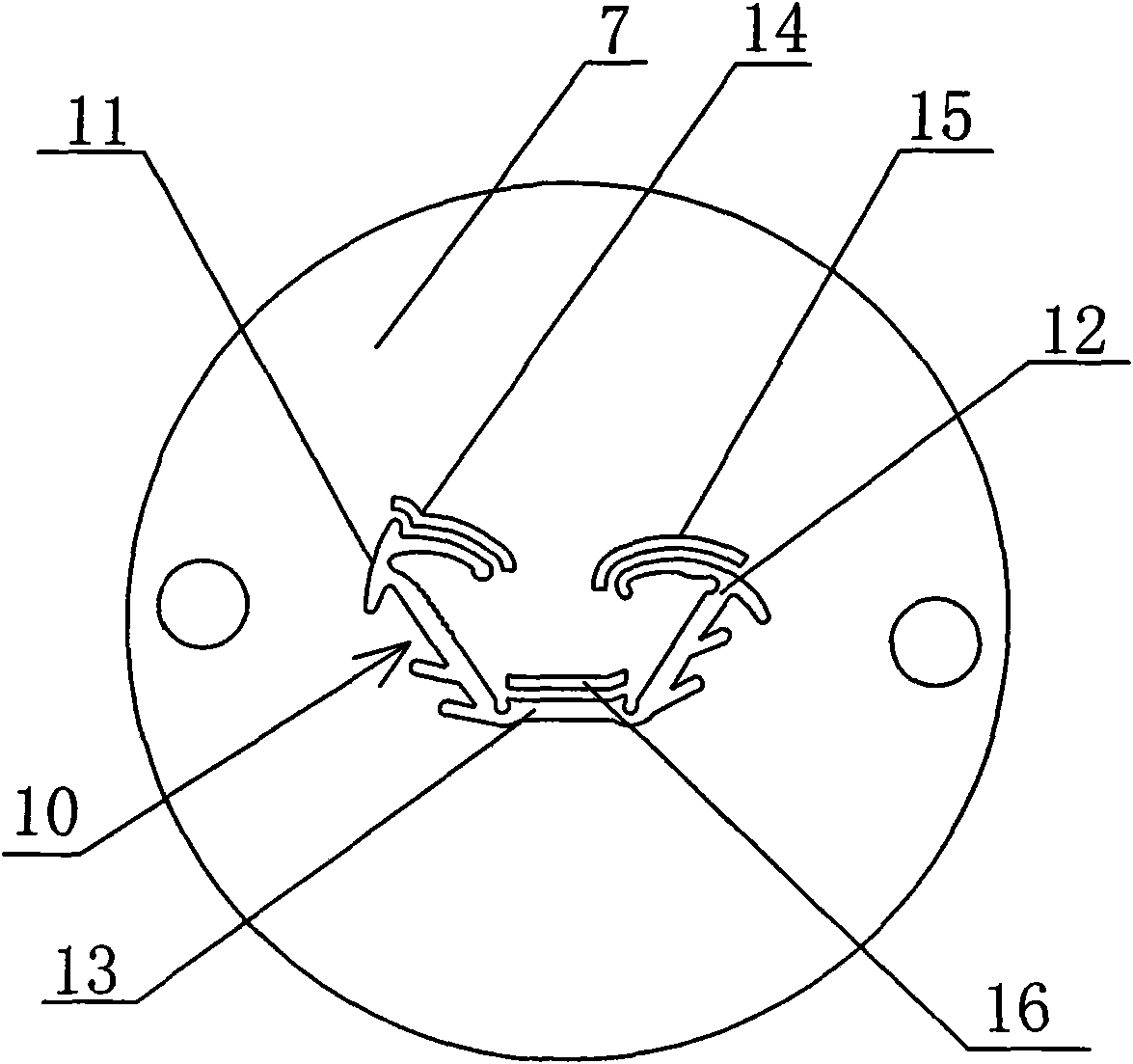

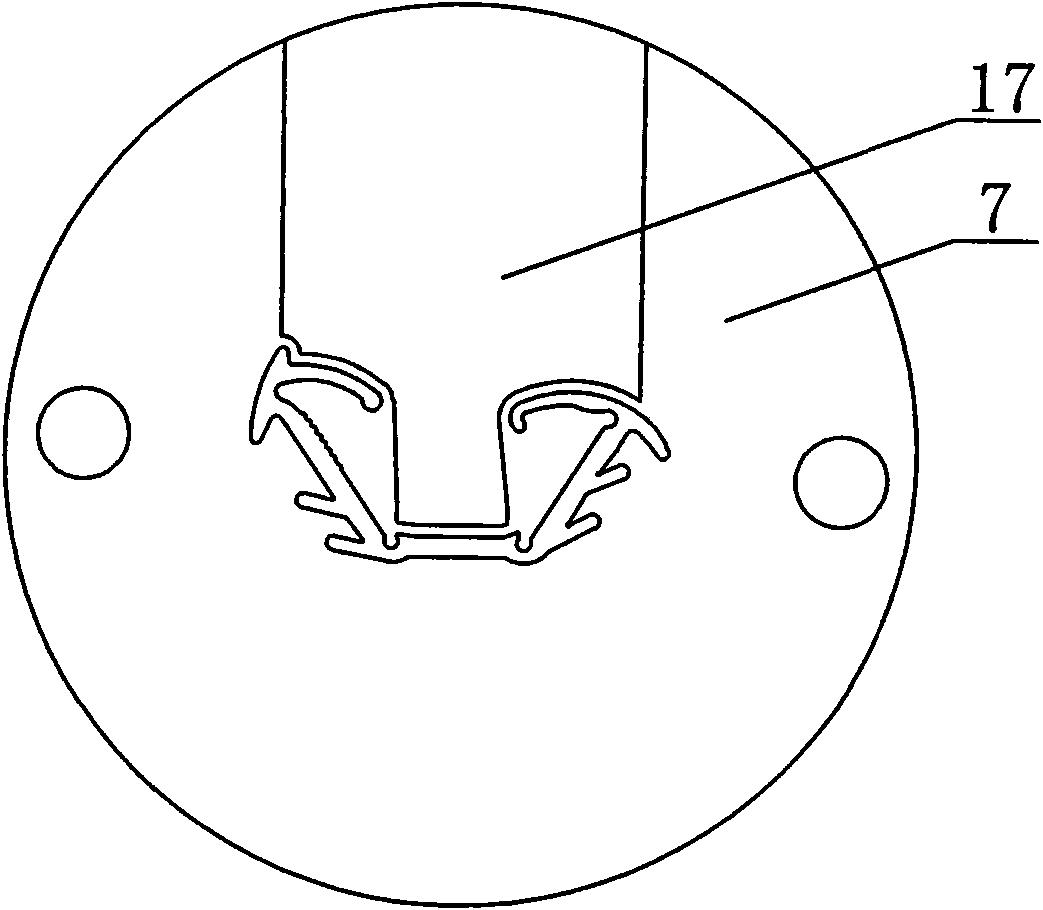

[0022] The invention is a special mold for producing the sealing strip of the automobile glass run channel. The sealing strip is characterized in that the upper wear-resistant layer 5 and the wear-resistant layer are respectively compounded on the left sealing clamping part 2, the right sealing clamping part 3 and the bottom surface 4 of the sealing strip base 1 made of base material (such as rubber). 22 and wear-resistant layer 23. The wear layer is made of TPV composite material (thermoplastic elastomer material) (see attached Figure 5 )

[0023] TPV thermoplastic elastomer material is a dynamic vulcanized rubber of EPDM and PP modified polyolefin. It has rubber-like performance, plastic-like processing technology, small specific gravity, non-toxic, strong wear resistance, can be used at -60°C to +130°C, has good aging resistance, and is an environmentally friendly material that can be recycled and reused.

[0024] The special mold for producing the sealing strip of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com