Water-proof sealing adhesive tape and its preparation method

A waterproof sealing, tape technology, applied in chemical instruments and methods, other chemical processes, paper/cardboard layered products, etc., can solve the problems of low tensile strength and peel strength, poor high and low temperature resistance, etc. High strength and peel strength, excellent high and low temperature resistance, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

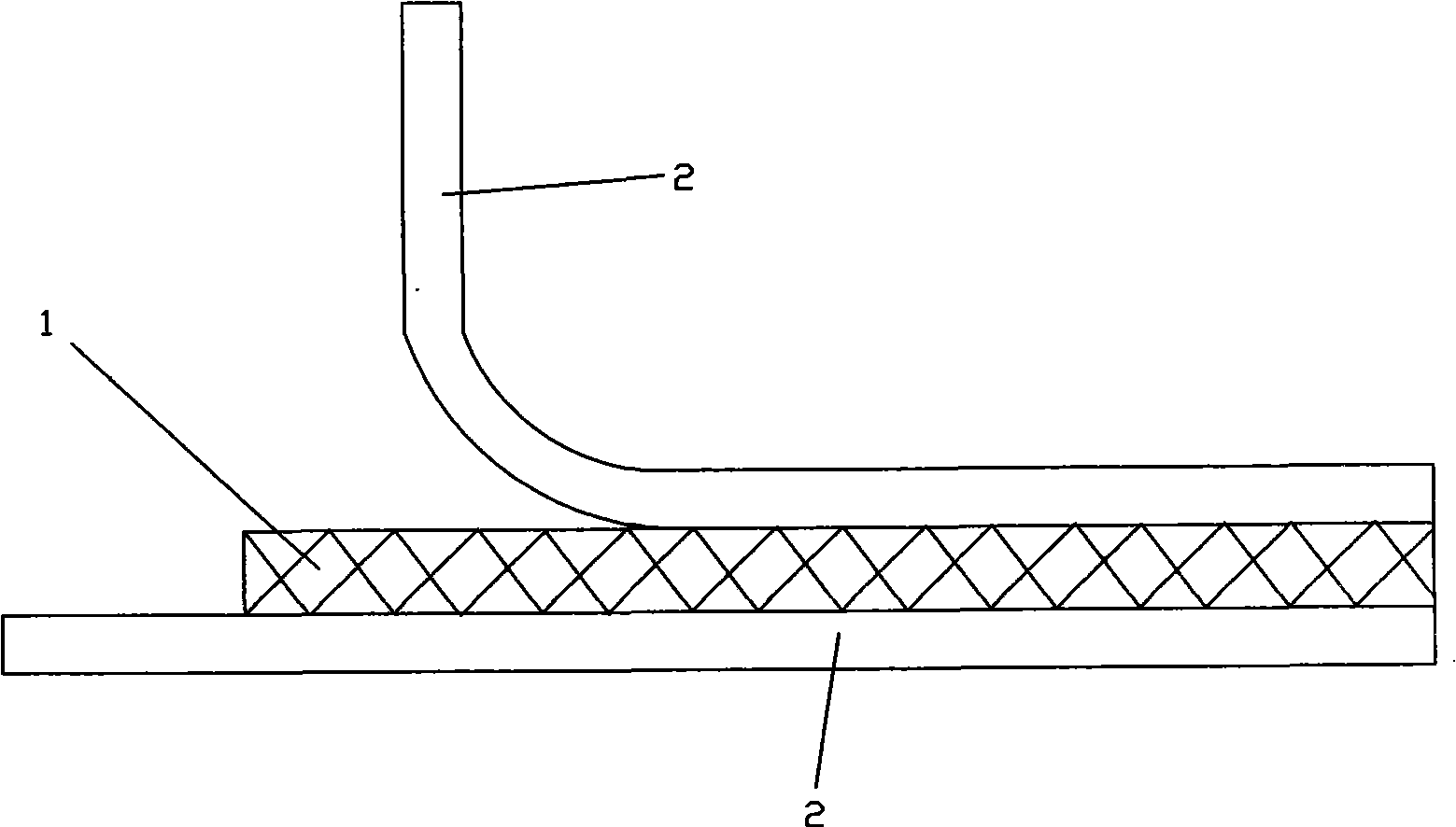

[0025] Take 100 parts of butyl rubber and 8 parts of ethylene-vinyl acetate copolymer (EVA). Repeatedly knead the above materials on an open mill at a temperature of 60°C until they are uniformly plasticized. Take them out and place them in an internal mixer, and add two 60 parts of silicon oxide, 15 parts of talc powder, 5 parts of terpene resin, 65 parts of polyisobutylene, 3 parts of iron red powder, 3 parts of dioctyl phthalate and 2,2,4-trimethyl-1,2- 1 part of dihydroquinoline polymer, fully mixed at room temperature to obtain a waterproof sealing layer 1, then cut into strips, put the strips into an extruder, and extrude them into strips with a width of 3 cm and a thickness of 0.8 mm. Then through the anti-adhesive oil paper 2 calender compound of its two sides, make waterproof sealing tape. The waterproof sealing tape prepared in this way has an insulation strength of 1.1*1014Ω cm, a peel strength of 1.0N / cm, a shear strength of 0.10Mpa, a tensile strength of 0.15Mpa, ...

Embodiment 2

[0028] Take 100 parts of butyl rubber and 25 parts of ethylene-vinyl acetate copolymer (EVA), and repeatedly knead the above materials on an open mill at a temperature of 60°C until the plasticization is uniform, take them out and put them in an internal mixer, and add two 80 parts of silicon oxide, 40 parts of talc powder, 15 parts of terpene resin, 105 parts of polyisobutylene, 10 parts of iron red powder, 10 parts of dibutyl phthalate and 2,6-di-tert-butyl-4-methylphenol 5 parts, mixed fully and evenly at room temperature to obtain the waterproof sealing layer 1, then cut into strips, put the strips into the extruder, extruded into strips with a width of 3cm and a thickness of 0.8mm, and then passed through the waterproof sealing layer on both sides. The sticky oil paper 2 is calendered and compounded to make a waterproof sealing tape. The insulating strength of the waterproof sealing tape thus prepared reaches 1.2*1014Ω·cm, the peel strength reaches 1.4N / cm, the shear stre...

Embodiment 3

[0031] Take 100 parts of butyl rubber and 15 parts of ethylene-vinyl acetate copolymer (EVA), and repeatedly knead the above materials on an open mill at a temperature of 60°C until the plasticization is uniform, take them out and put them in the internal mixer, and add two 70 parts of silicon oxide, 28 parts of talcum powder, 80 parts of polyisobutylene, 2 parts of epoxy resin, 5 parts of iron red powder, 5 parts of epoxy soybean oil and 3 parts of 2-mercaptobenzimidazole zinc salt, fully Knead evenly to obtain a waterproof sealing layer 1, then cut into strips, put the strips into an extruder, extrude them into strips with a width of 3cm and a thickness of 0.8mm, and then compound them by calendering with the anti-sticking oil paper 2 on both sides. Waterproof sealing tape. The waterproof sealing tape prepared in this way has an insulation strength of 1.2*1014Ω·cm, a peel strength of 1.2N / cm, a shear strength of 0.12Mpa, a breaking strength of 0.12Mpa, and a breaking elongat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com