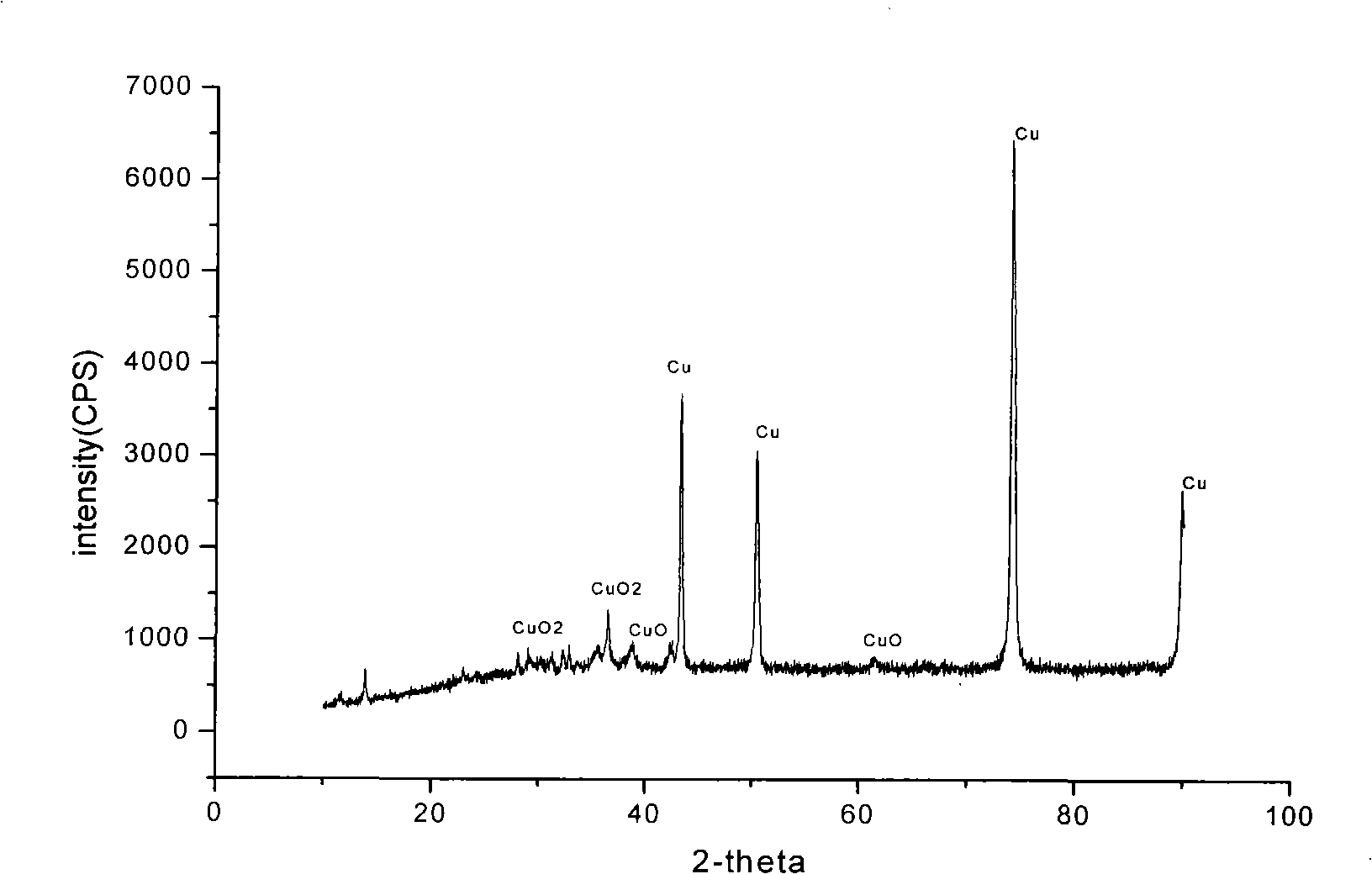

CuO straw-shaped nano structure and preparation method thereof

A nanostructure and straw technology, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problem of high cost of plasma, achieve good repeatability, save resources, and reduce requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Polish the copper sheet, clean it with ultrasonic waves, and then cut it into several small pieces about 1cm×1.5cm;

[0024] 2) Take 10 ml of KOH solution of 10M / L (mole per liter) and put it into a 50 ml beaker;

[0025] 3) Put the copper piece into a small beaker and let it stand for 60 minutes;

[0026] 4) Take 15 milliliters of hydrogen peroxide with a graduated cylinder, and then drop the hydrogen peroxide (concentration 30%) into the beaker with a dropper at a constant speed;

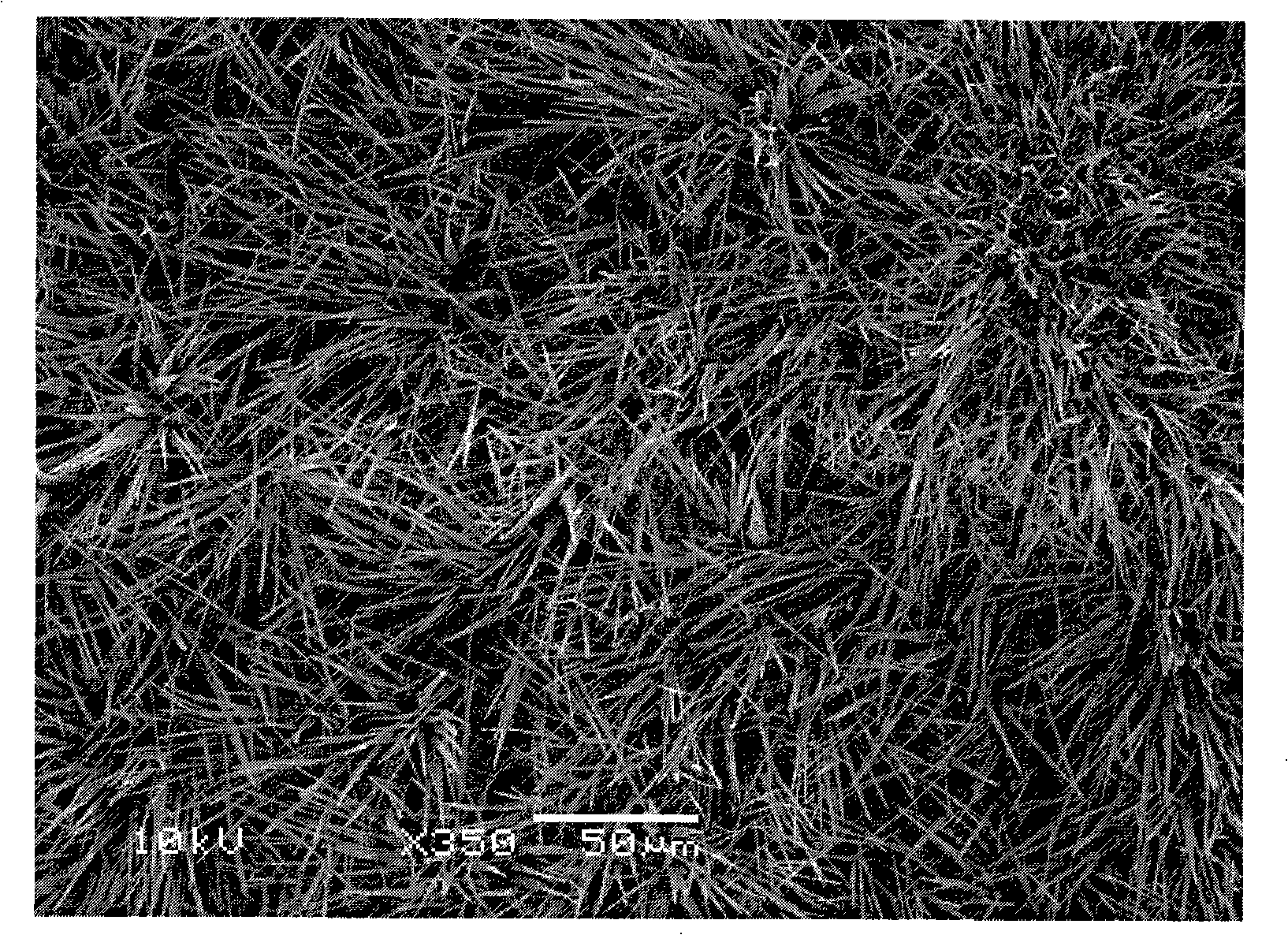

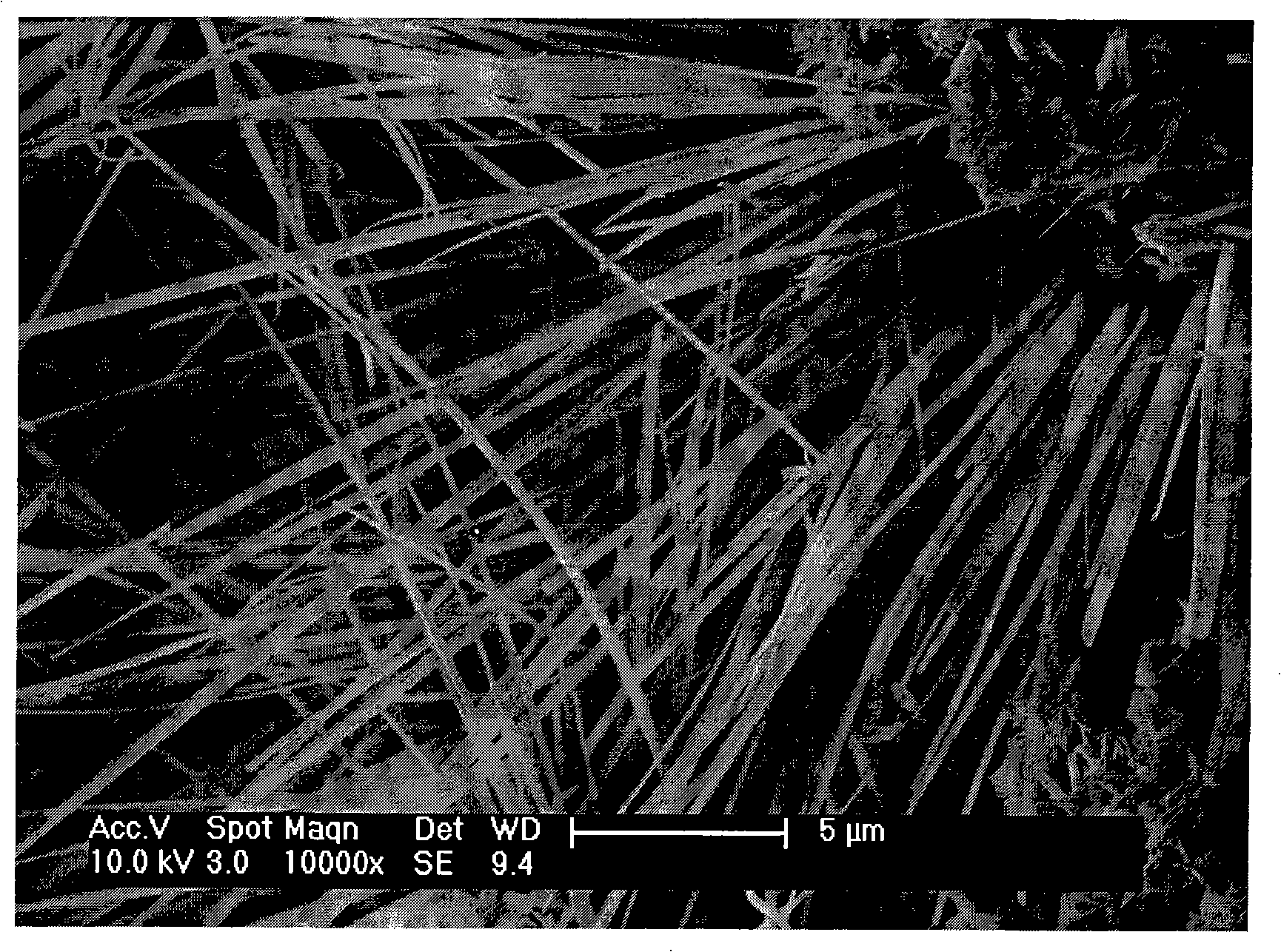

[0027] 5) After the reaction was carried out for 12 hours, the copper sheet whose surface was completely blackened was taken out;

[0028] 6) Clean the surface of the copper sheet with deionized water and alcohol, and dry it in a constant temperature oven at 60°C;

[0029] 7) Take it out from the oven, and you can see clusters of black copper oxide raised on the surface.

Embodiment 2

[0031] 1) Polish the copper sheet, clean it with ultrasonic waves, and then cut it into several small pieces about 1cm×1.5cm;

[0032] 2) Take 12 milliliters of KOH solution of 10M / L (mole per liter) and put it into a 50 milliliter beaker;

[0033] 3) Put the copper piece into a small beaker and let it stand for 65 minutes;

[0034] 4) Take 15 milliliters of hydrogen peroxide with a graduated cylinder, and then drop the hydrogen peroxide (concentration 30%) into the small beaker with a dropper at a constant speed;

[0035] 5) After the reaction was carried out for 12 hours, the copper sheet whose surface was completely blackened was taken out;

[0036] 6) Clean the surface of the copper sheet with deionized water and alcohol, and dry it in a constant temperature oven at 65°C;

[0037] 7) Take it out from the oven, and you can see clusters of black copper oxide raised on the surface.

Embodiment 3

[0039] 1) Polish the copper sheet, clean it with ultrasonic waves, and then cut it into several small pieces about 1cm×1.5cm;

[0040] 2) Take 15 ml of KOH solution of 10M / L (mole per liter) and put it into a 50 ml beaker;

[0041] 3) Put the copper piece into a small beaker and let it stand for 70 minutes;

[0042] 4) Take 20 milliliters of hydrogen peroxide with a graduated cylinder, and then drop the hydrogen peroxide (concentration 30%) into the beaker with a dropper at a constant speed;

[0043] 5) After the reaction was carried out for 13 hours, the copper sheet whose surface was completely blackened was taken out;

[0044] 6) Clean the surface of the copper sheet with deionized water and alcohol, and dry it in a constant temperature oven at 70°C;

[0045] 7) Take it out from the oven, and you can see clusters of black copper oxide raised on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com