Molding circuit component and process for producing the same

A technology for forming circuits and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuit components, printed circuits, etc., can solve the problems of reduced yield rate, limited application field, and difficulty in widening the width of the non-forming surface 10c of the circuit, and achieves Effects of preventing short circuits and widening the utilization area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

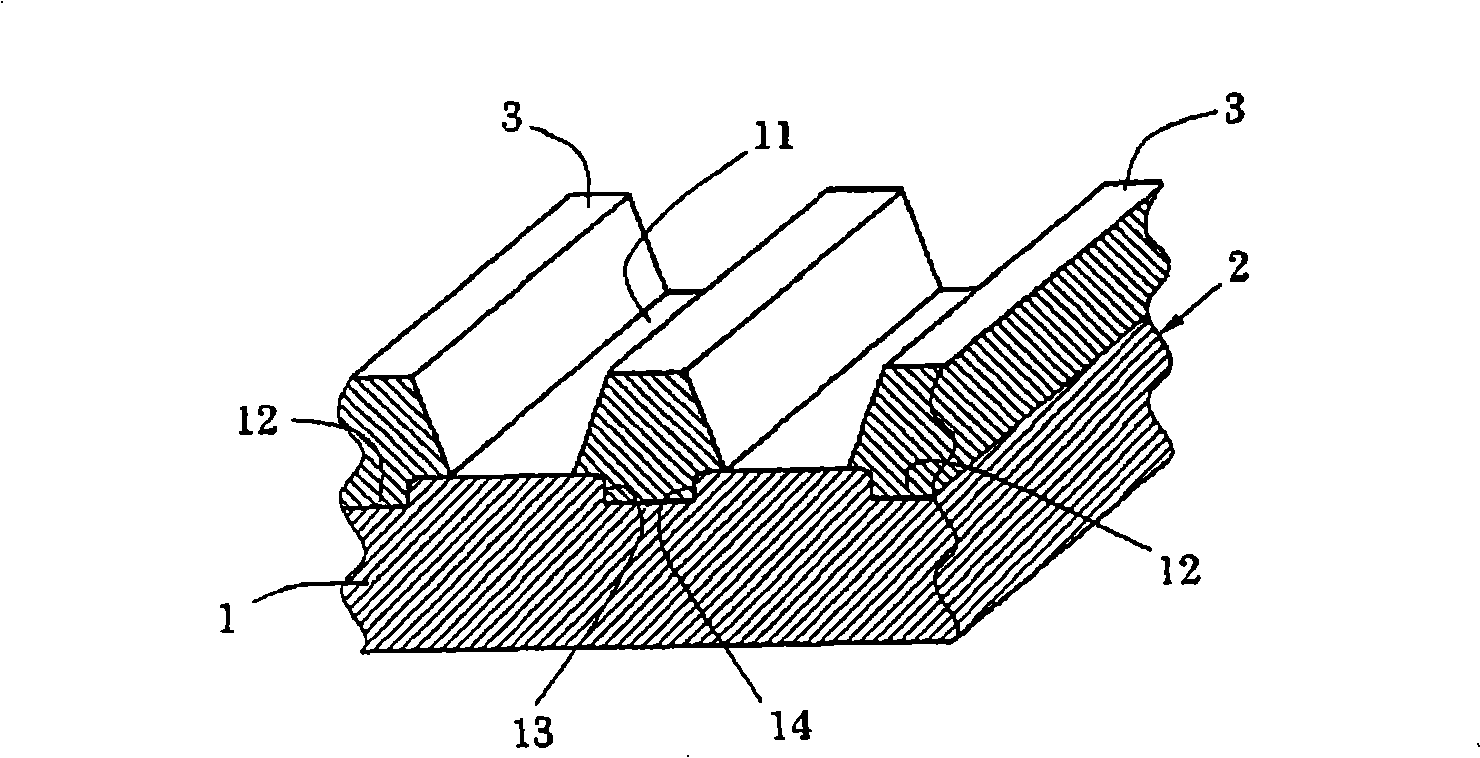

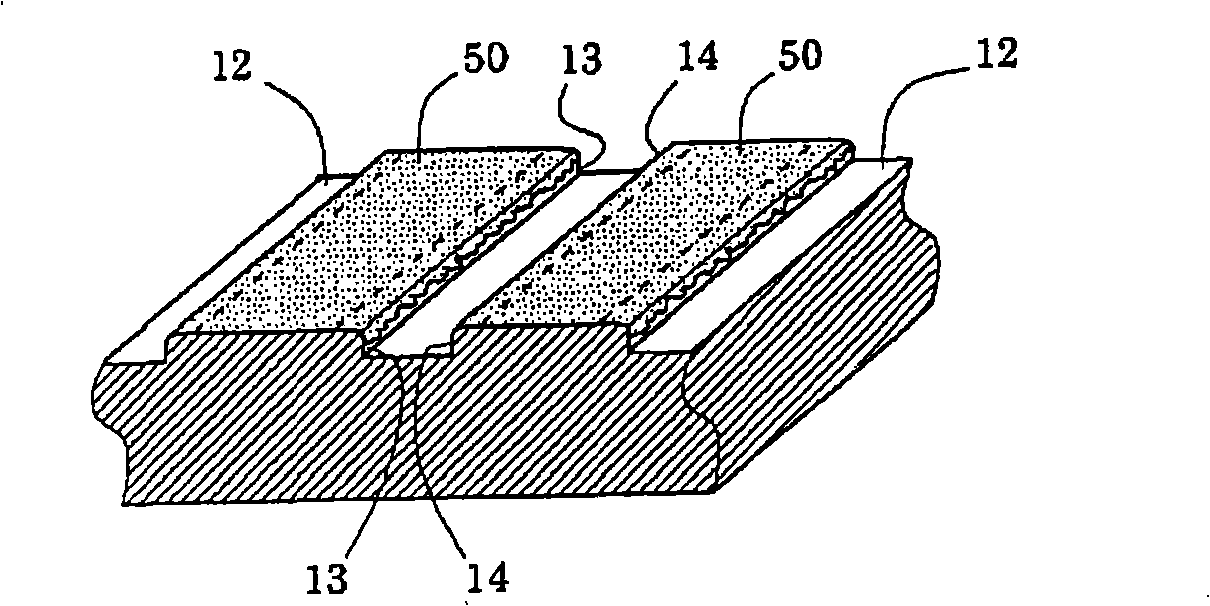

[0046] refer to Figure 1 ~ Figure 3 Illustrate the embodiment of the present invention, in figure 1 Among them, the primary substrate 1 is formed by injection molding the "VECTRA C820" of liquid crystal polymer. Its shape is that the circuit forming surface 11 is convex, and the circuit non-forming surface 12 is concave, and the height difference is formed as 0.05mm. The angle of the side walls 13 and 14 connecting the circuit-forming surface and the circuit-non-forming surface is formed at 90°. Furthermore, the surface of the primary substrate 1 is roughened with a caustic soda solution.

[0047] The circuit forming surface 11 on which the conductive layer 50 is formed is exposed, and the resin mask 3 covering the concave circuit non-forming surface 12 is injection-molded. The state of about mm. As the material of the resin mask 3, "ECOMATY AX-2000" of the said Nippon Gosei Kagaku Kogyo of polyvinyl alcohol system was used.

[0048] In order to apply the catalyst, the s...

Embodiment 2

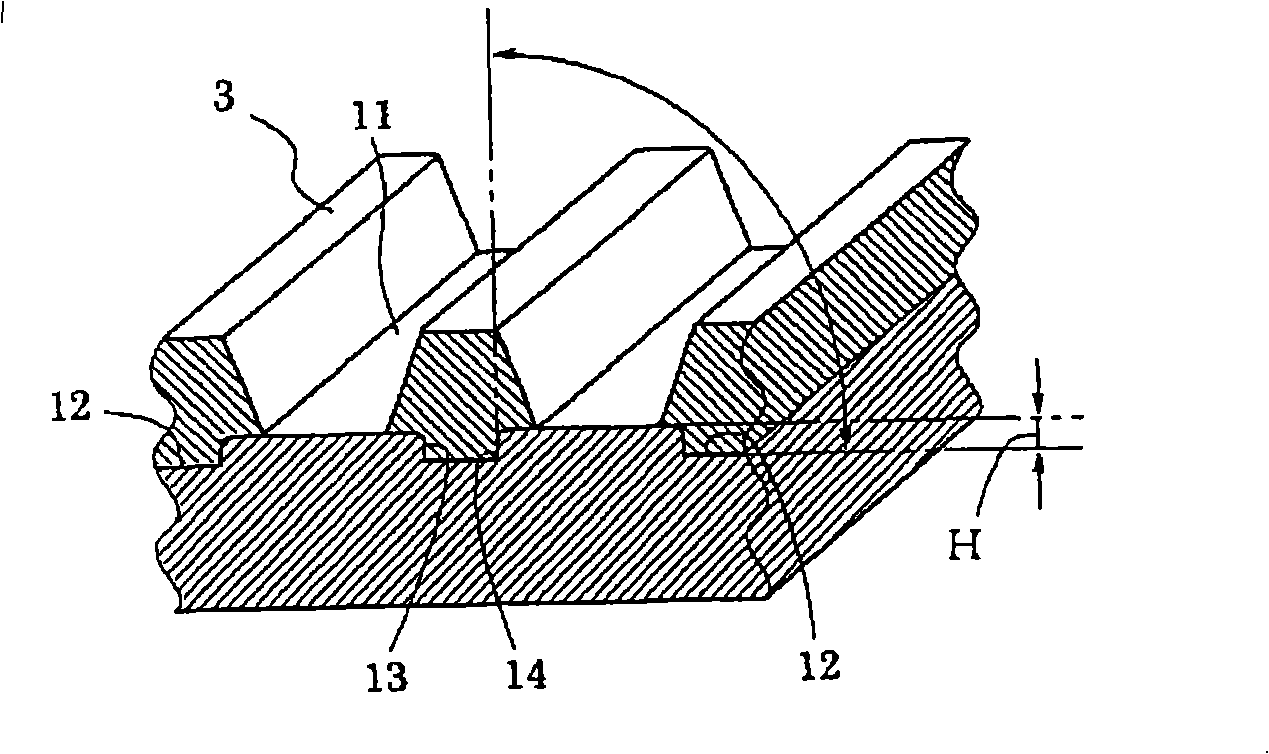

[0060] refer to Figure 4 ~ Figure 6 Illustrate embodiment 2 of the present invention, in image 3 The primary substrate 6 is formed by injection molding the "VECTRA C820" of liquid crystal polymer. Its shape is that the circuit forming surface 61 is concave, and the circuit non-forming surface 62 is convex, and its height difference H is as follows: Image 6 It is shown that the formation is 0.2 mm, and the inclination angle of the non-circuit formation portion is formed at 80°. Furthermore, the surface of the primary substrate 6 is roughened with a caustic soda solution.

[0061] The circuit-forming surface 61 on which the conductive layer 50 is formed is exposed, and the resin mask 31 covering the convex non-circuit-forming surface 62 is injection-molded. , forming the secondary matrix 2 in the coated state. As the material of the resin mask 31, "ECOMATY AX-2000" of the said Nippon Gosei Kagaku Kogyo of polyvinyl alcohol system was used.

[0062] In order to apply the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circuit width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com