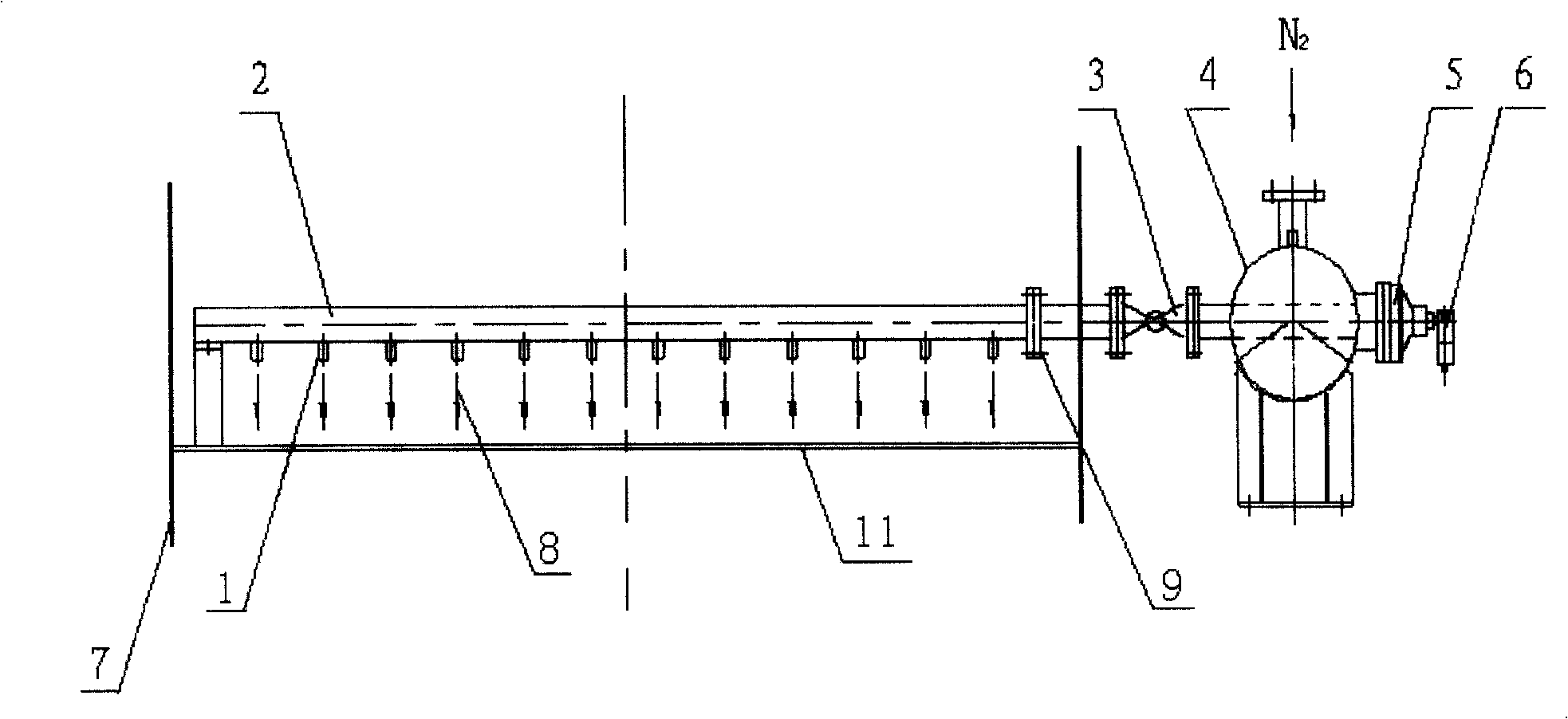

Blast furnace gas dust removing device and technique by dry method

A technology of dry dust removal and blast furnace gas, which is applied in the direction of gas dust removal, chemical industry, climate sustainability, etc., and can solve the problems of low output of blast furnace gas residual pressure power generation facilities, high dust content of clean gas, and high water content of clean gas , to achieve the effect of eliminating washing water, strong dust removal ability and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

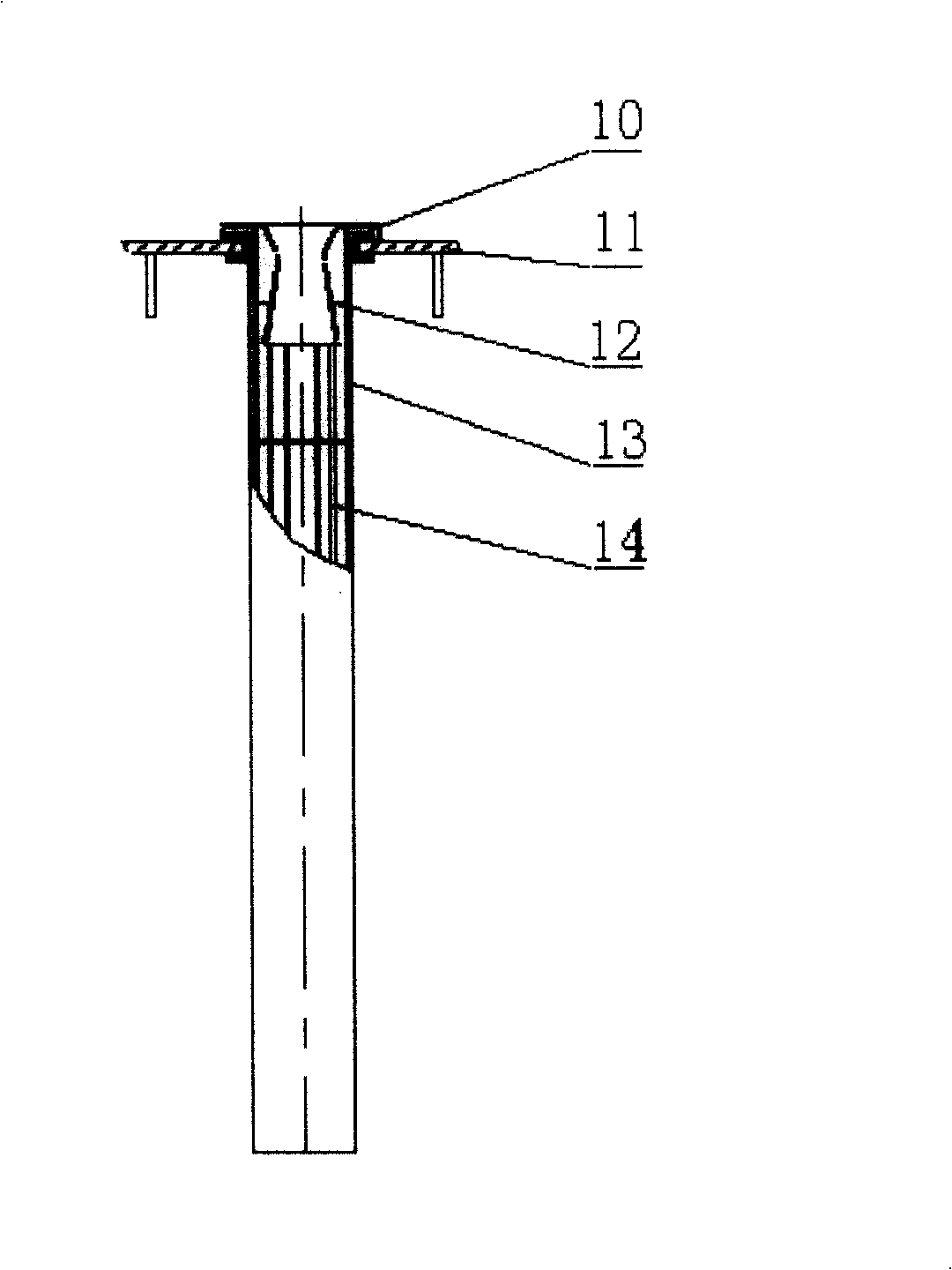

Method used

Image

Examples

Embodiment Construction

[0019] The following will be further described in conjunction with examples.

[0020] The present invention is implemented in 4# blast furnace of Baotou Steel, and the concrete conditions such as blast furnace process parameters are shown in the table below.

[0021] Baotou Steel 4# blast furnace process parameter table

[0022] serial number

project

Process parameters

1

Blast furnace volume

2200m 3

2

Top gas pressure

Maximum pressure: 0.25MPa, normal pressure: 0.18MPa, normal

Furnace top pressure: 0.04MPa

3

gas flow

Maximum: 460,000nm 3 / h, normal: 420,000nm 3 / h

Atmospheric pressure: 240,000nm 3 / h

4

gas temperature

Normal: ~200°C, Accident: ~280°C

5

Raw gas dust content

Normal: ≤5~10g / m 3 , Atmospheric pressure: ≤10g / m 3

6

Net gas dust content

≤8mg / m 3

7

Filtration wind speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com