White polyester solar energy battery back film and preparation method thereof

A solar cell and polyester technology, applied in the field of polyester film, can solve the problems that the surface coating layer is easily scratched and damaged, can only be used for decoration, packaging, and cannot be used as a protective film for solar cells, etc. Light-shielding and aging resistance, good light-shielding, and the effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

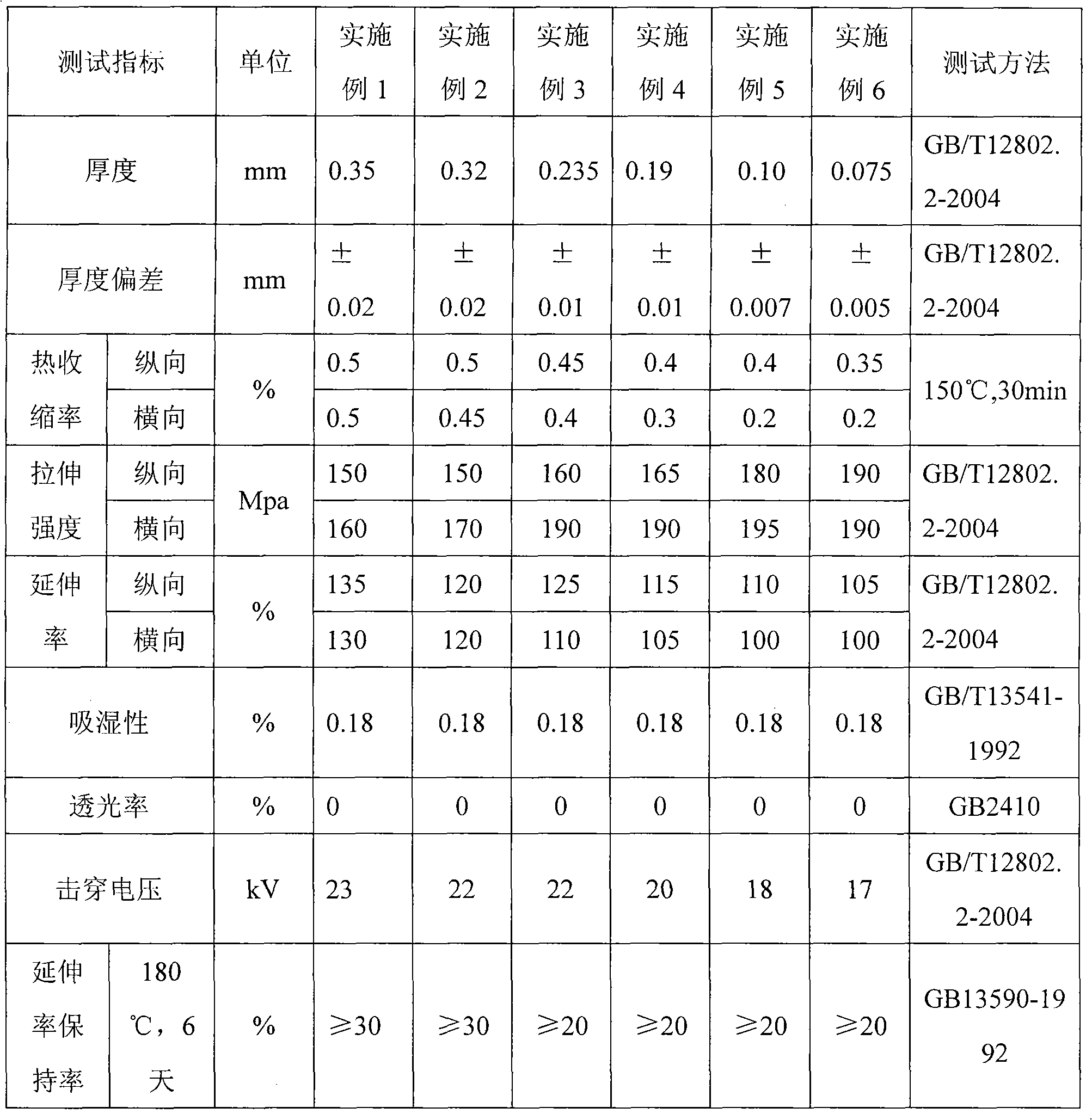

[0014] The white polyester solar battery back film of the present invention is composed of polyester chips and white polyester masterbatch components. Slicing adopts bottle grade or film grade, and the specific weight parts are as shown in Table 1,

[0015] Table 1

[0016] component name

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

Polyester chips

1

3

5

6

8

9

White polyester masterbatch

1

1

1

1

1

1

[0017] Percentage by weight, the white polyester masterbatch of the present invention has the following components: 35%-89.4% polyester chips, 0.5%-10% silicon dioxide, 10%-50% titanium dioxide and 0.1-5% As for the ultraviolet light absorber, silicon dioxide is treated with an organic surface and has a particle size of 10-100nm, and titanium dioxide is treated with an organic surface and has a particle size of 100-1000nm. The white polyester masterbatch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com