Novel orthopaedics medicaments carrier system and preparation thereof

A carrier system and drug technology, applied in the direction of drug delivery, drug combination, pharmaceutical formulation, etc., can solve the problems of slow degradation, incomplete degradation, no osteoconductivity and osteoinductivity, and achieve high reactivity and good biological phase. Capacitive, good biodegradable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

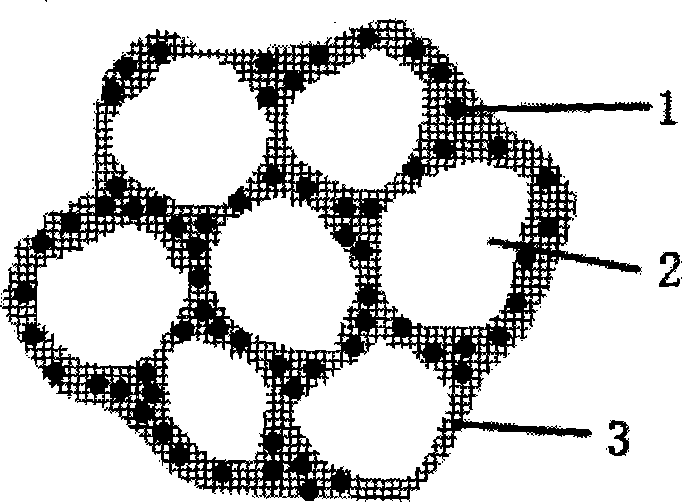

[0038] Embodiment 1 bioactive glass-based vancomycin drug carrier

[0039] Analytical pure Na 2 CO 3 , CaCO 3 , H 3 BO 3 , Na 2 HPO 4 As the raw material, prepare the batch according to the glass composition in Table 1. After mixing the batch evenly, melt it in a platinum crucible at 1100-1150°C for 2 hours to obtain a bubble-free molten glass, and finally quench the molten glass , to obtain a transparent devitrification-free glass block. Crush the block, grind and sieve to get the glass powder between 25-50 μm.

[0040] Table 1 Chemical composition of bioactive glass

[0041] Chemical composition (wt%)

[0042] Na 2 O CaO 2 o 3 P 2 o 5

[0043] 10 24 60 6

[0044] In addition, 40 mg of vancomycin was dissolved in 0.2 ml of phosphoric acid solidification buffer, stirred well, and 1 g of sieved glass powder was added, stirred evenly, and then filled into the mold. Pressurize at 10MPa and maintain for 15s. After demoulding, put it...

Embodiment 2

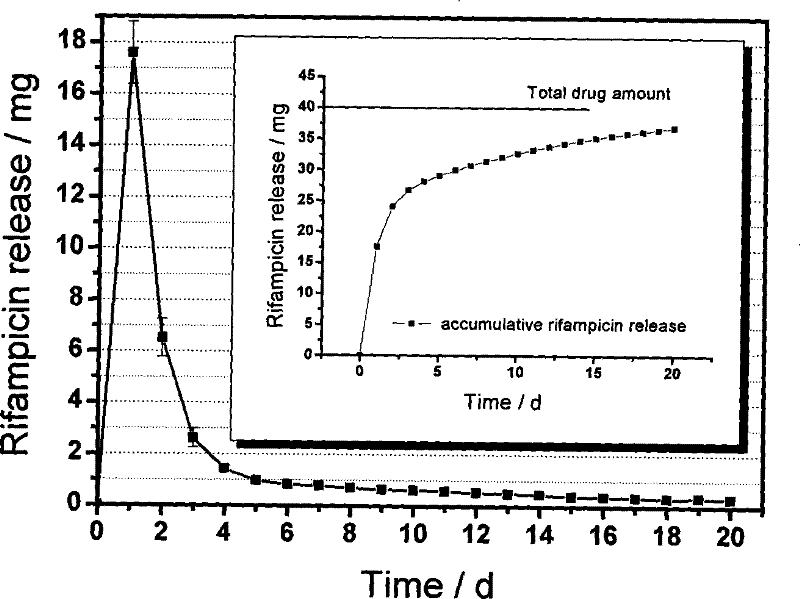

[0047] Embodiment 2 bioactive glass-based rifampicin drug carrier

[0048] Use analytically pure Na2CO3, CaCO3, H3BO3, SiO2, Na 2 HPO 4 As raw materials, batches were prepared according to the glass composition shown in Table 2. After mixing the batch materials evenly, melt in a platinum crucible at 1200-1250°C for 2 hours to obtain bubble-free molten glass, and finally quench the molten glass to obtain transparent devitrification-free glass. Grind and sieve the glass powder between 25 and 50 μm. Fully mix 40mg rifampicin and 700mg glass powder, drop into 0.2ml phosphoric acid solidification buffer, stir well and fill it into the mold. Form freely without applying pressure. The mold is placed in an environment with a humidity >95% and a temperature of 37° C. for aseptic curing for 5 hours, and the drug carrier is obtained by demoulding. The drug strength is 15-20MPa.

[0049] Table 2 Chemical composition of bioactive glass

[0050] Chemical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com