Manufacturing method of glasses elastic hinge case

A technology of elastic hinges and manufacturing methods, which is applied in the direction of manufacturing tools, glasses/goggles, and other manufacturing equipment/tools, and can solve the problems of increased cutting difficulty, complicated manufacturing process, and limited bar width, so as to facilitate subsequent processing, Good production continuity, eliminating the effect of bending and not straight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

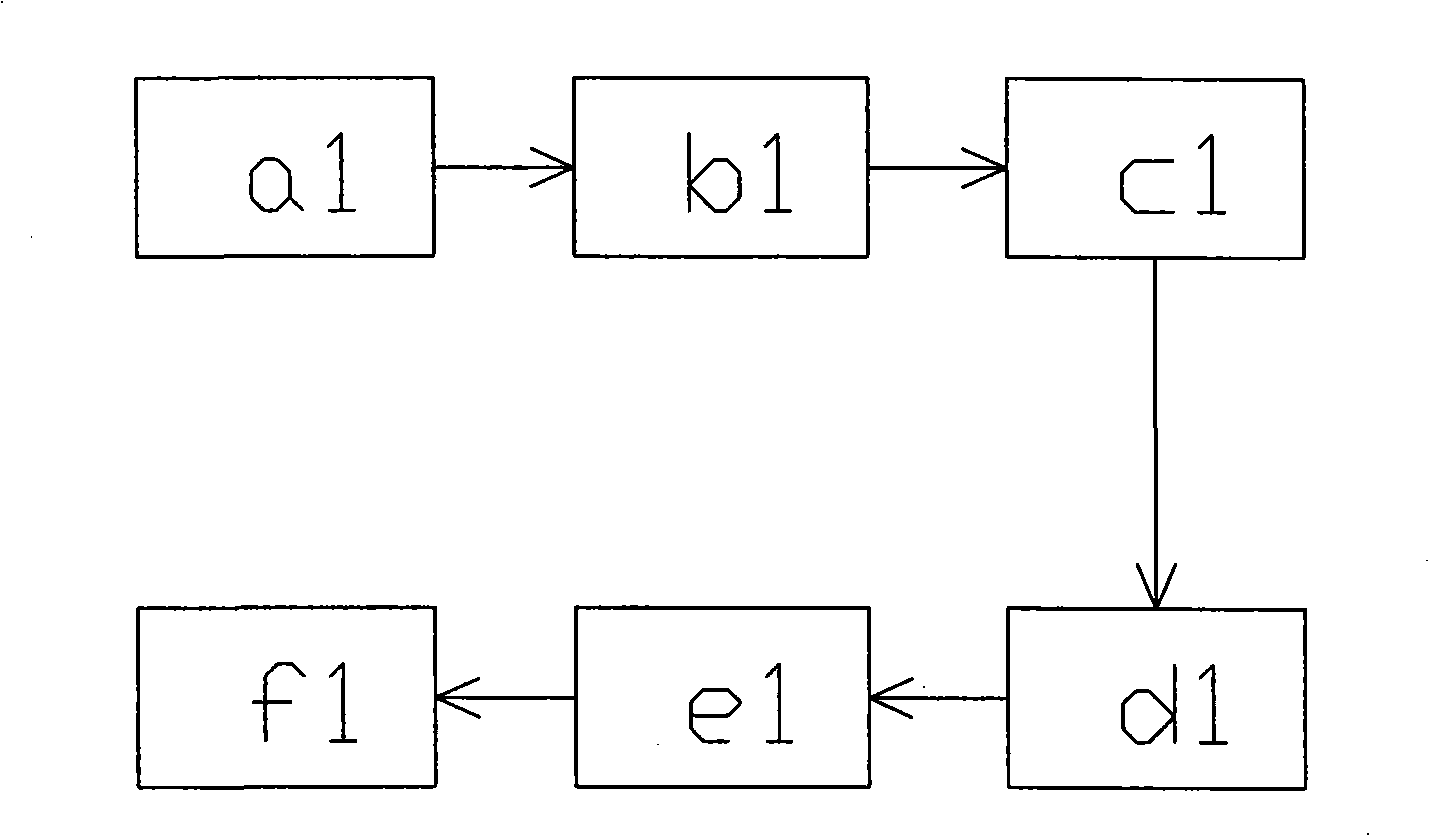

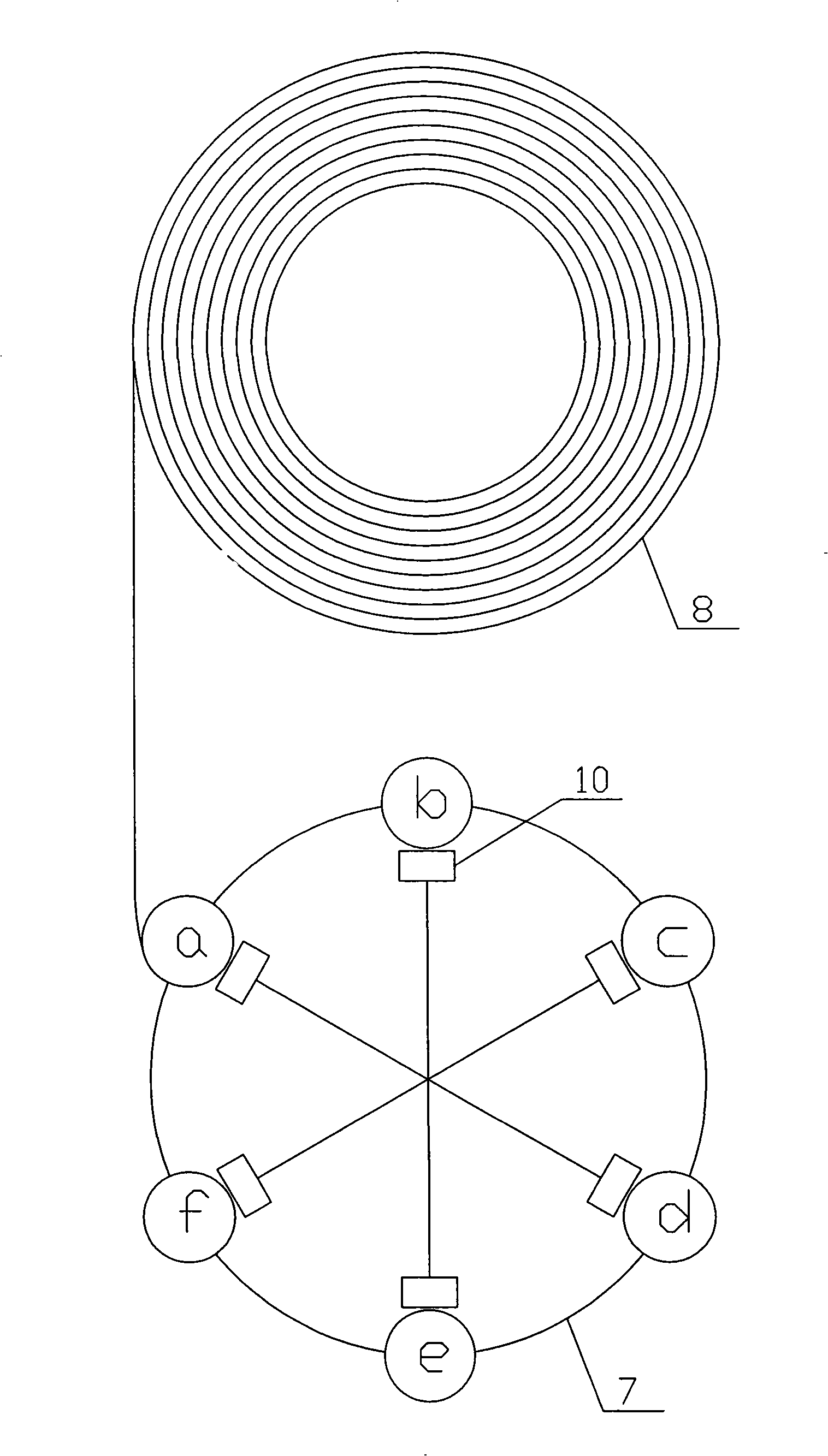

[0029] Example 1 as image 3 ~ As shown in Figure 7, a method for manufacturing the elastic hinge shell of glasses, including six stations arranged in sequence: a. cutting station, b. top milling station, c. punching station, d. Tail milling station, e. boring station, f. punching station, the six stations are distributed around the periphery of the rotary table type combined machine tool 7, and the middle of the rotary table type combined machine tool is provided with the same number of stations Six fixtures 10; the six fixtures are uniformly distributed and coaxially arranged in the circumferential direction, and can rotate synchronously. During work, the shell blanks are clamped one by one, and the shell blanks are stepped and sent to the circle around the periphery of the turntable combined machine tool according to the rotation direction of the turntable combined machine tool. At multiple stations, each functional part of the shell blank is processed when the fixture stop...

Embodiment 2

[0036] Example 2 as Figure 8 ~ Figure 1 As shown in 2, compared with embodiment 1, a milling station g and corresponding fixtures are added to the rotary table type combined machine tool 7 used in embodiment 2, and the milling station is located at the boring station e and the punching station Between stations f; seven fixtures are uniformly distributed and coaxially arranged in the circumferential direction, and can rotate synchronously. During work, the shell blanks are clamped one by one, and the shell blanks are sent to the surrounding rotary table type machine tool 7 in steps according to the rotation direction of the rotary table type combined machine tool. At multiple stations on the periphery, each functional part of the shell blank is processed when the fixture stops at the corresponding station, so that the cycle is repeated to achieve continuous production; the two sides and the bottom of the shell blank do not need to be processed, and the two sides are fixtures c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com