Automatic bag feeding machine for valve bags

A valve pocket and automatic technology, applied in the direction of object separation, pile separation, thin material processing, etc., can solve the problems of high labor intensity, low work efficiency, poor production continuity, etc., and achieve the effect of improving production continuity and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

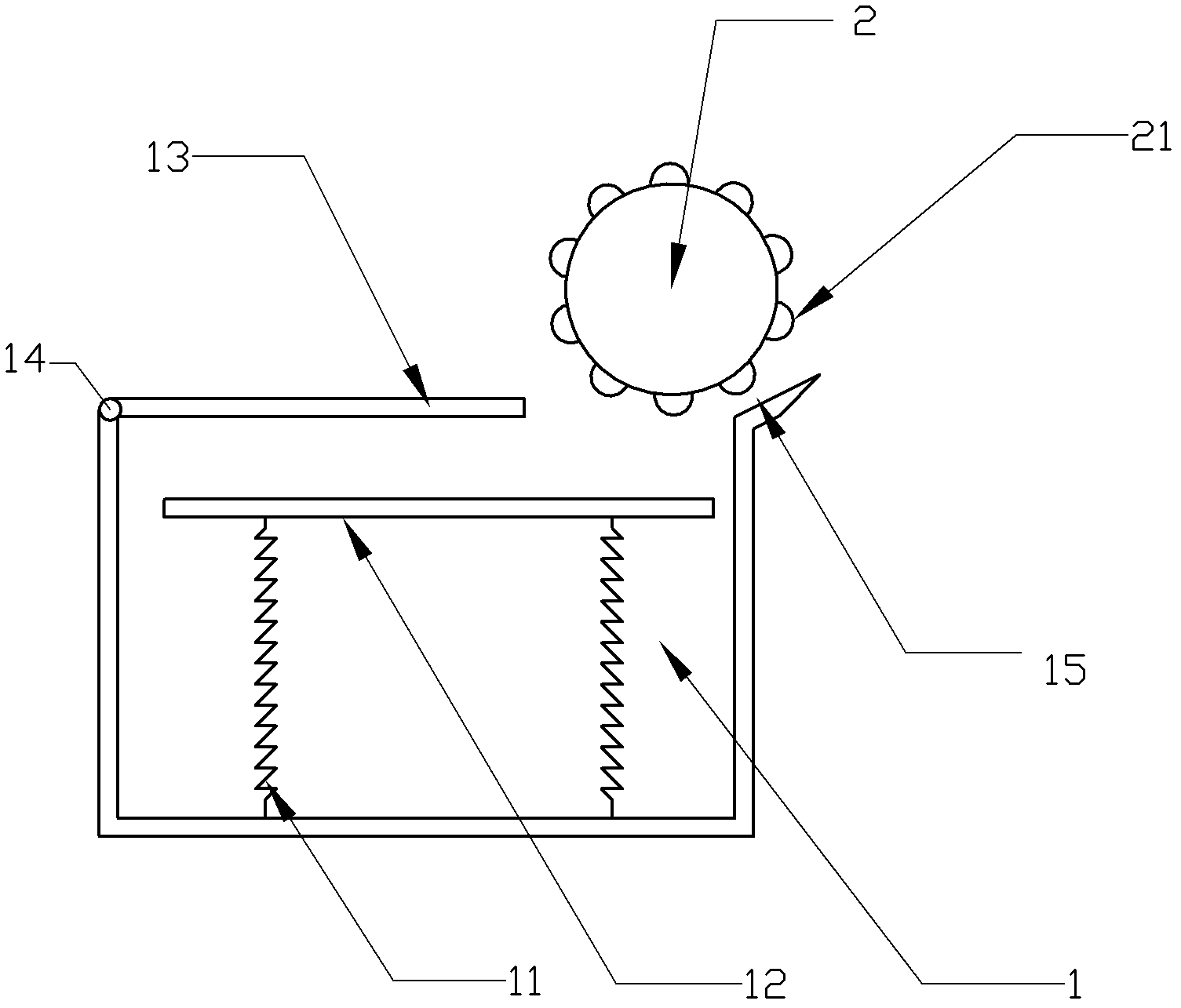

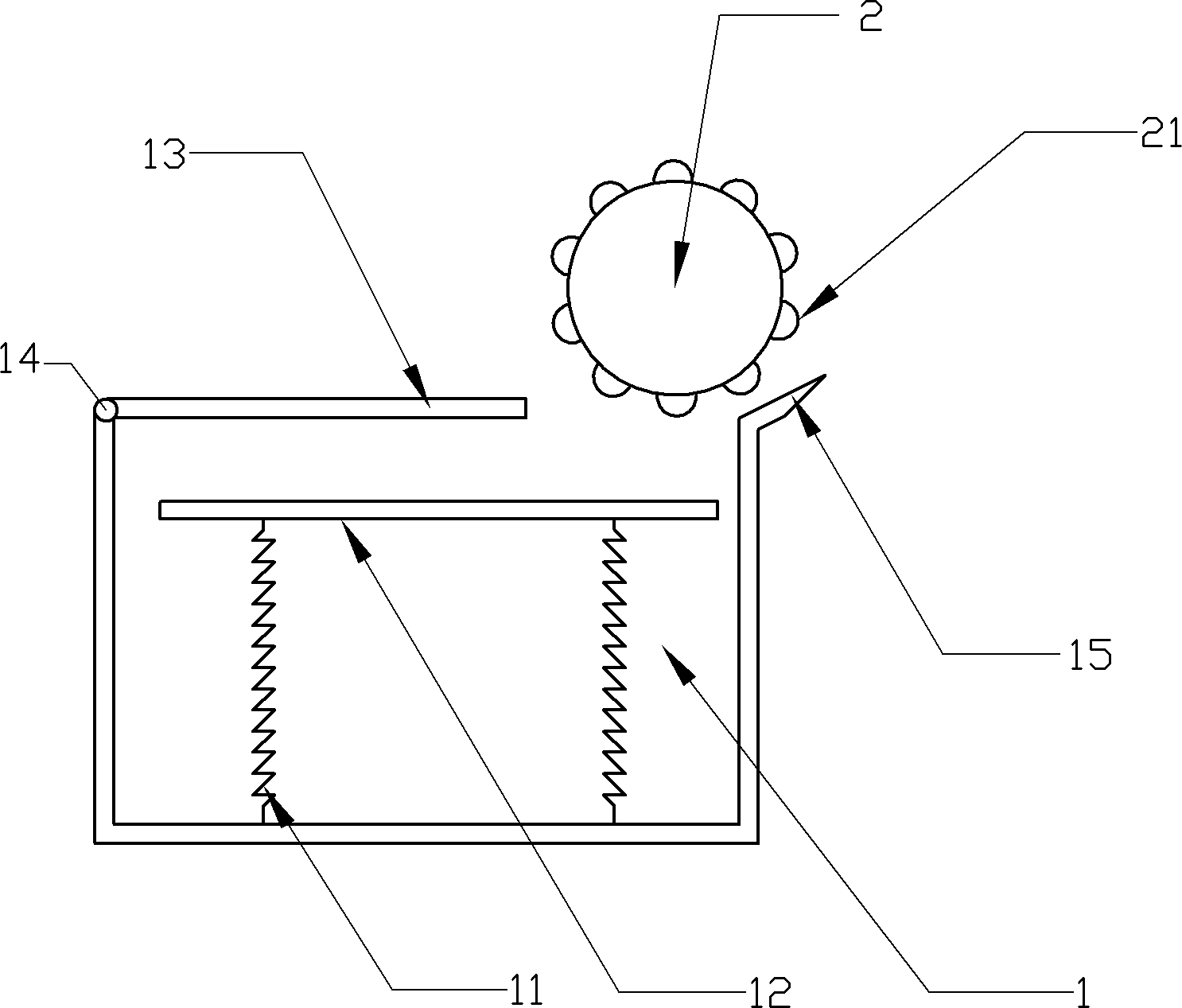

[0012] Attached below in conjunction with the instructions figure 1 To further describe the present invention:

[0013] Such as figure 1 As shown, a valve bag automatic bagging machine includes a bagging box 1 and a bag rubbing roller 2. The bagging box 1 is open on the upper side, and one side of the opening is hinged with a top cover 13 through a hinge point 14. The top cover is smaller than The opening of the bagging box can be turned outward around the hinge point 14 to add valve pockets. The bottom of the bagging box 1 is equipped with a spring 11, the spring is preferably a leaf spring, a bag holding plate 12 is connected to the spring 11, and the bagging box 1 is provided with an inner lower and outer lower surface on the vertical surface near the bag inlet direction. The high matching inclined surface 15 cooperates with the bag rubbing roller 2 to realize the material shifting.

[0014] The lowest point of the mating inclined surface 15 is located below the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com