Catalytic reaction, rectification integrated technique and special-purpose equipment

A catalytic reaction and rectification technology, which is applied in the direction of unsaturated compound addition to ether, chemical industry, hydroxyl addition preparation, etc., can solve the problems of increased operating cost, low production efficiency, equipment corrosion, etc., and achieve the reaction conversion rate Improvement, reduction of corrosion of equipment, and improvement of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

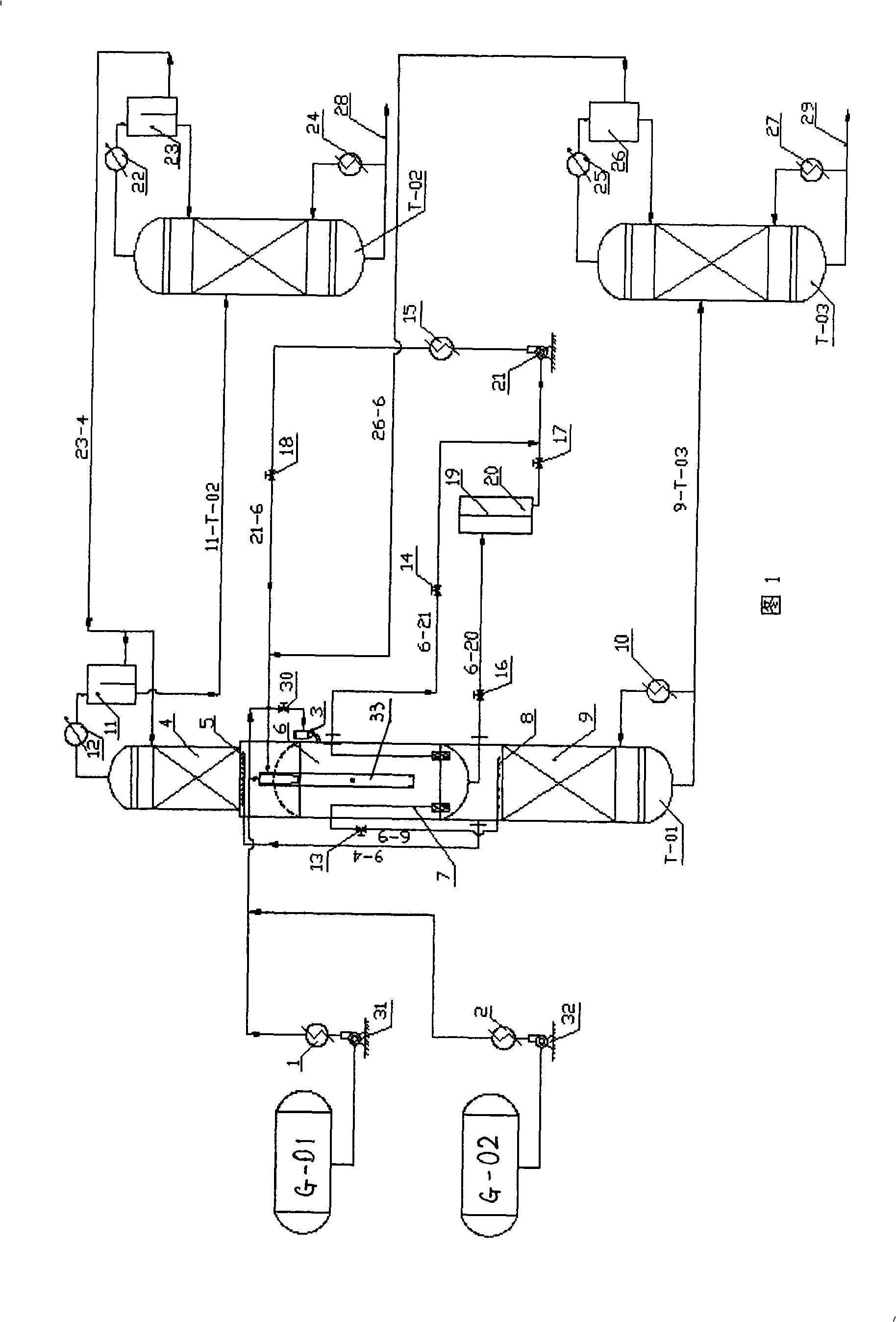

[0033] Embodiment 1: Esterification produces butyl acetate (three tower system)

[0034] The production device is shown in Figure 1. The catalytic reaction and rectification integrated tower T-01 has a diameter of 0.4 meters and a total height of 12 meters, of which the height of the reaction section 6 is 1.5 meters, the height of the rectification section 4 is 4.5 meters, and the stripping section 9 and The height of the tower kettle is 6 meters, and the catalyst adopts high temperature resistant strong acid ion exchange resin. The height of the dehydration tower T-02 is 9 meters, of which the height of the rectification section is 3 meters, and the height of the stripping section and the tower kettle is 6 meters. The height of T-03 is 26 meters, of which the rectification section is 10 meters high, and the stripping section and tower still are 16 meters high. The operation process is as follows:

[0035] The ratio of the amount of acetic acid and n-butanol is 1:1.1 and ent...

Embodiment 2

[0039] Embodiment 2: hydration reaction produces dihydromyrcenol (three tower system)

[0040] Using dihydromyrcene as a raw material, it reacts with water under the action of an acidic catalyst to produce dihydromyrcenol, a high-grade fragrance raw material. Catalytic reaction and rectification integrated tower T-01 has a diameter of 1.2 meters and a total height of 28 meters, of which the height of reaction section 6 is 2.5 meters, the height of rectification section 4 is 14.5 meters, the height of stripping section 9 and tower still is 11 meters, and the catalyst High temperature resistant strong acid ion exchange resin is used. The height of T-02 is 25 meters, of which the rectification section is 10 meters high, and the stripping section and tower still are 15 meters high. The height of T-03 is 36 meters, of which the rectification section is 16 meters high, and the stripping section and tower still are 20 meters high. The operation process is as follows:

[0041] The ...

Embodiment 3

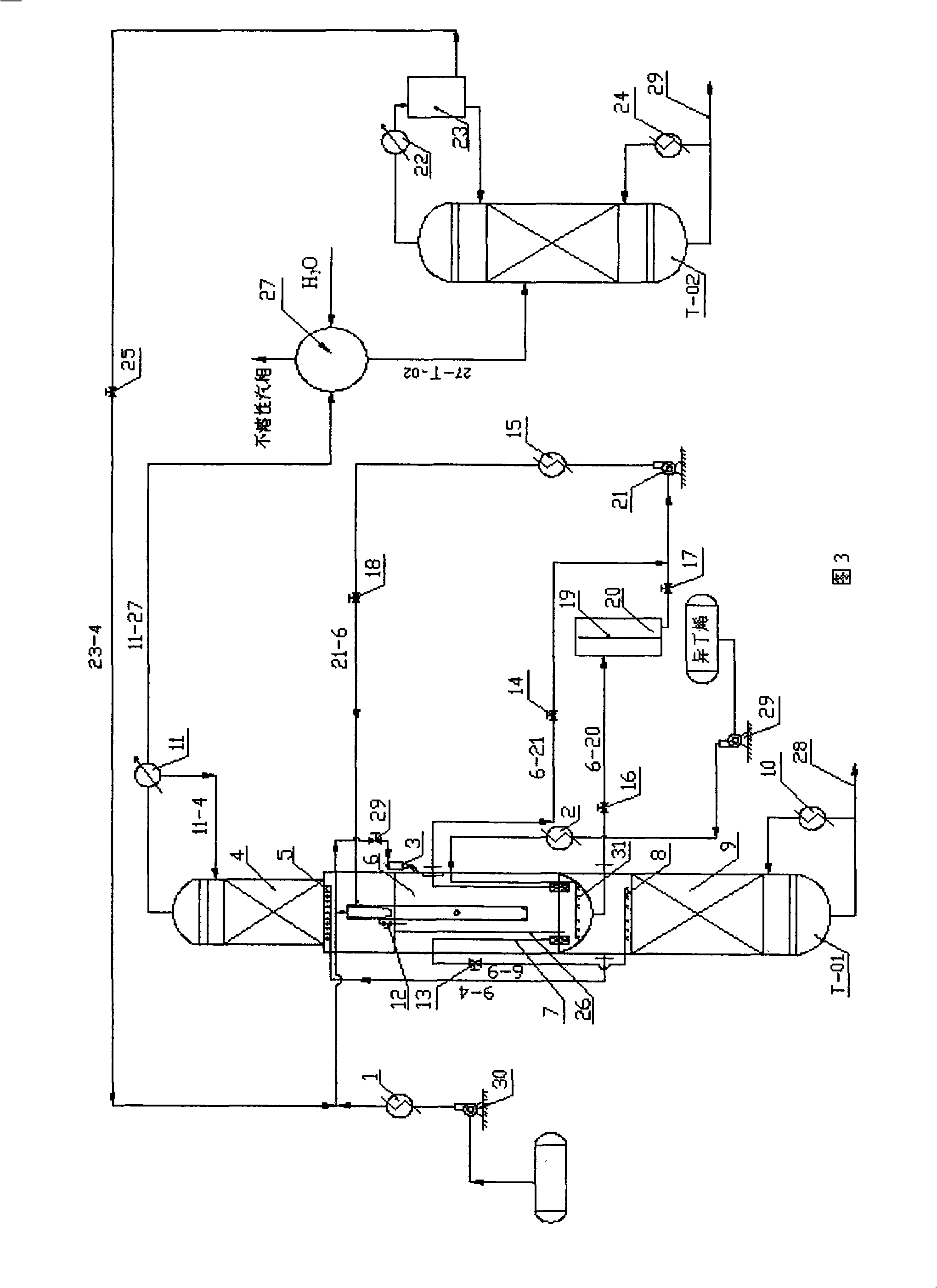

[0045] Embodiment 3: methanol and isobutylene etherification reaction produces MTBE (two tower system)

[0046] Using methanol and isobutylene as raw materials, using AMBERLYST-15 catalyst (provided by Tianjin Weide International Trade Co., Ltd.), the important chemical methyl tert-butyl ether (MTBE for short) can be obtained through etherification. The catalytic reaction and rectification integrated tower T-01 used in this embodiment has a diameter of 0.3 meters and a total height of 18 meters, wherein the height of the reaction section 6 is 1.2 meters, the height of the rectification section 4 is 8 meters, and the height of the stripping section 9 and the tower still It is 8.8 meters. The height of the dehydration tower T-02 is 35 meters, of which the height of the rectification section is 15 meters, and the height of the stripping section and the tower kettle is 20 meters. Its operation process is as follows:

[0047]After the liquid-phase industrial-grade methanol is hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com