Technique for synthesizing dihydromyrcenol

A technology of dihydromyrcenol and synthesis process, which is applied in the preparation of oxygen-containing compounds, preparation of organic compounds, organic chemistry and other directions, can solve the problems of low yield, loss, and poor content of finished products, and achieves rectification and purification. The effect of improving the yield, improving the content yield of the finished product, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

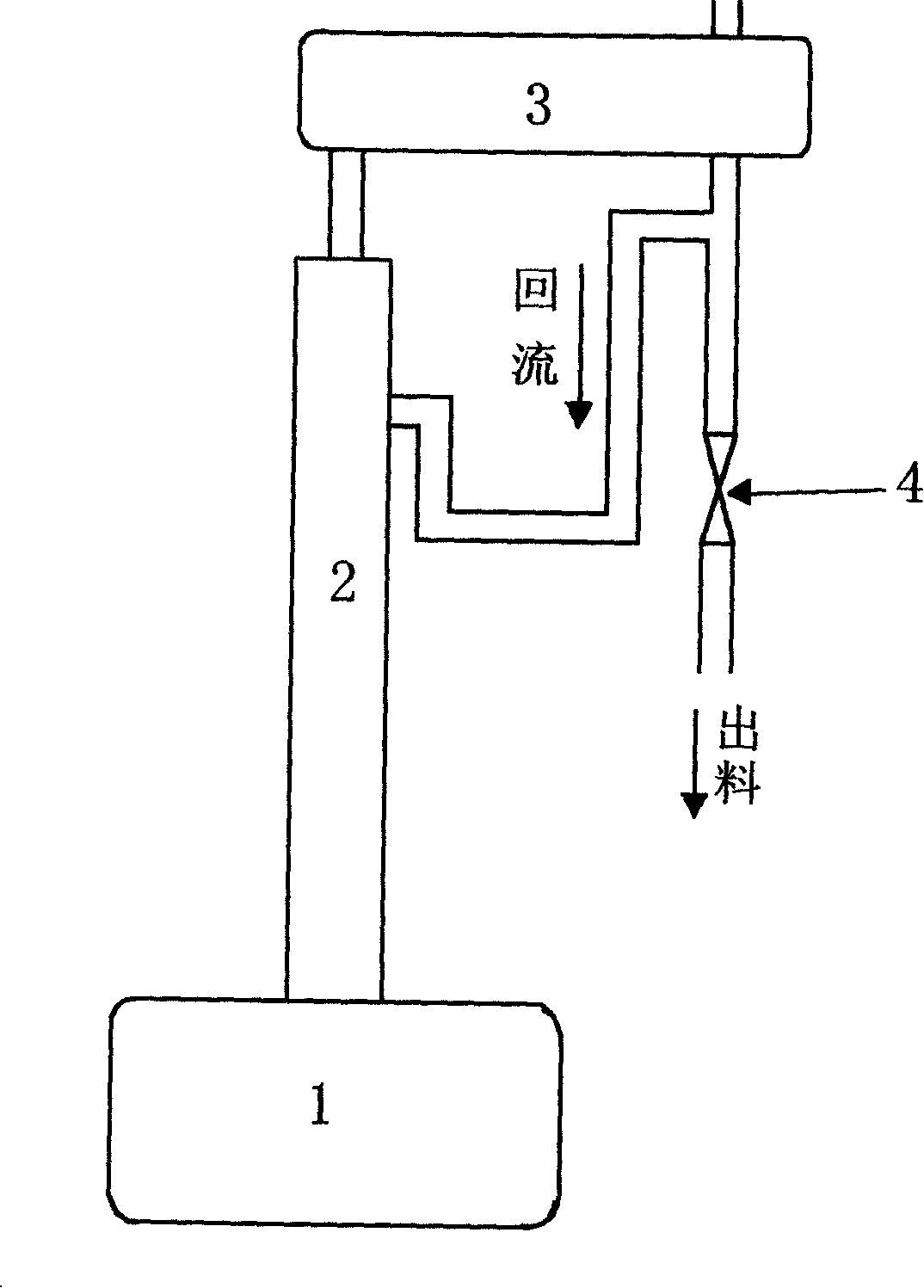

[0028] Drop into 2200 kilograms of turpentine (content 78% α-pinene, 10% β-pinene) in rectification tower still, rectify in the stainless steel corrugated net rectification tower of 80 purpose, and use the installed above the receiving tank The valve is used to control the reflux ratio. After 35 hours, 1720 kg of 96.5% α-pinene is rectified once, and the rectification amount of α-pinene is 55 kg / hour.

[0029] Under the condition of 40-50°C, add 30kg NaOH to the enamel reaction pot, add desalted water to make a 30% NaOH solution, slowly add 36kg nickel-aluminum alloy at a speed of 8kg / h, and use a tube to put the hydrogen in the hydrogen bottle Hydrogen is passed into the reaction pot at a rate of 20 L / h, and the outside is cooled with cold water to keep the temperature at 40-50° C. to obtain nickel powder. Under the condition of filling hydrogen, the nickel powder obtained above is washed to keep the catalyst activity, and a nickel skeleton catalyst is obtained.

[0030] In ...

Embodiment 2

[0033] Drop into 3400 kilograms of turpentine (content 78% α-pinene, 10% β-pinene) in rectification tower kettle and rectify in the stainless steel corrugated net rectification tower of 80 order, and use the valve installed above the receiving tank To control the reflux ratio, through 45 hours, 2665 kilograms of rectification 96.5% α-pinene, rectification amount is 65 kilograms / hour.

[0034] In the reactor, add the α-pinene of above-mentioned gained, add the nickel skeleton catalyst activation catalyst that makes in the embodiment 1 namely above-mentioned gained nickel skeleton catalyst 2.7 kilograms, add sodium bicarbonate 17kg, hydrogenation gas pressure is at 7-8kg, The outside is cooled with cold water to keep the temperature at 80-100° C. to obtain 2665 kg of 95% pinane, and the hydrogenation rate is 160 kg / hour.

[0035] Pinane is cracked in a vacuum state, the cracking flow rate is 63 kg / hour, and 2655 kg of dihydromyrcene with a content of 65% is obtained, and 88% dih...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com