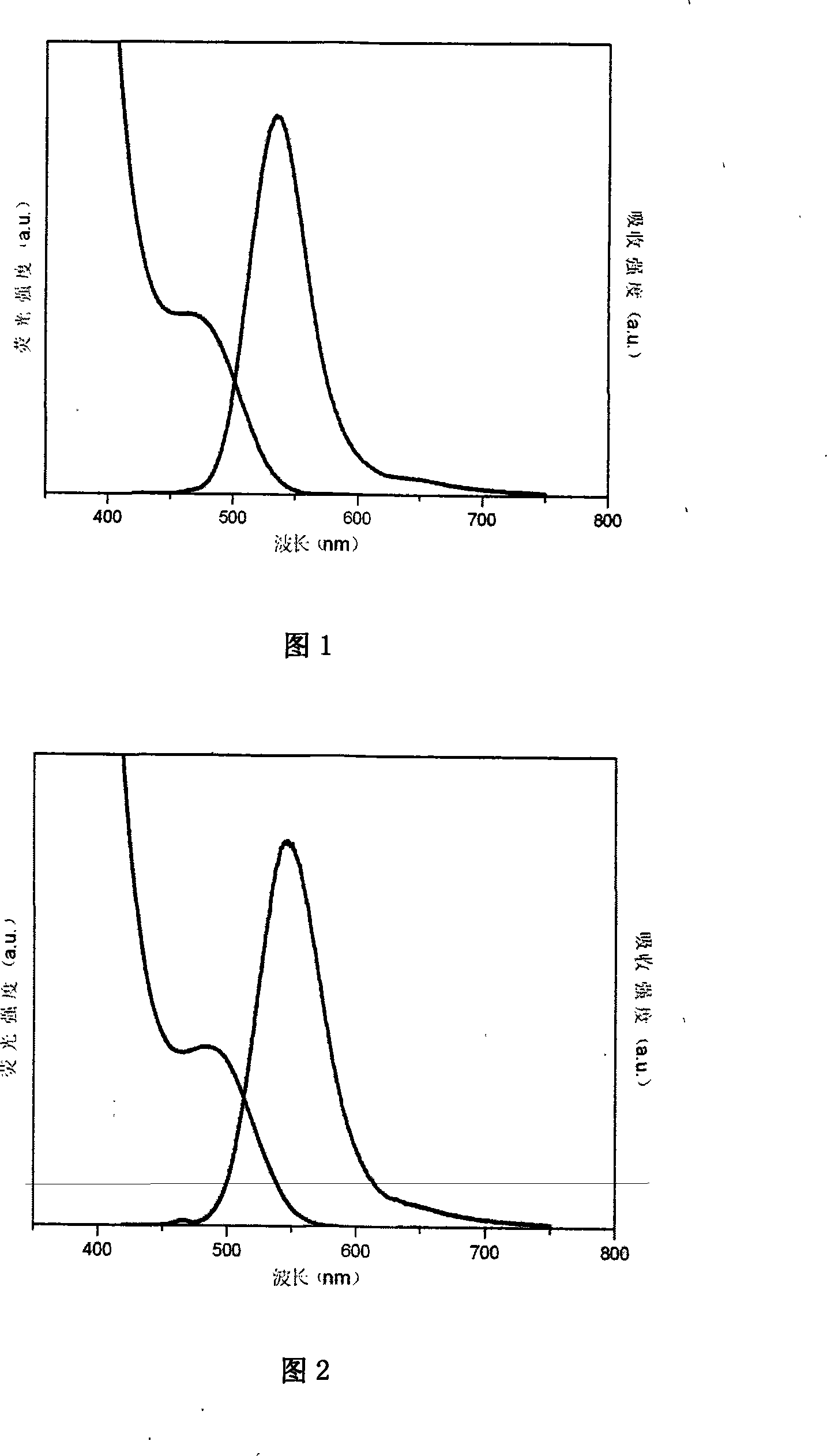

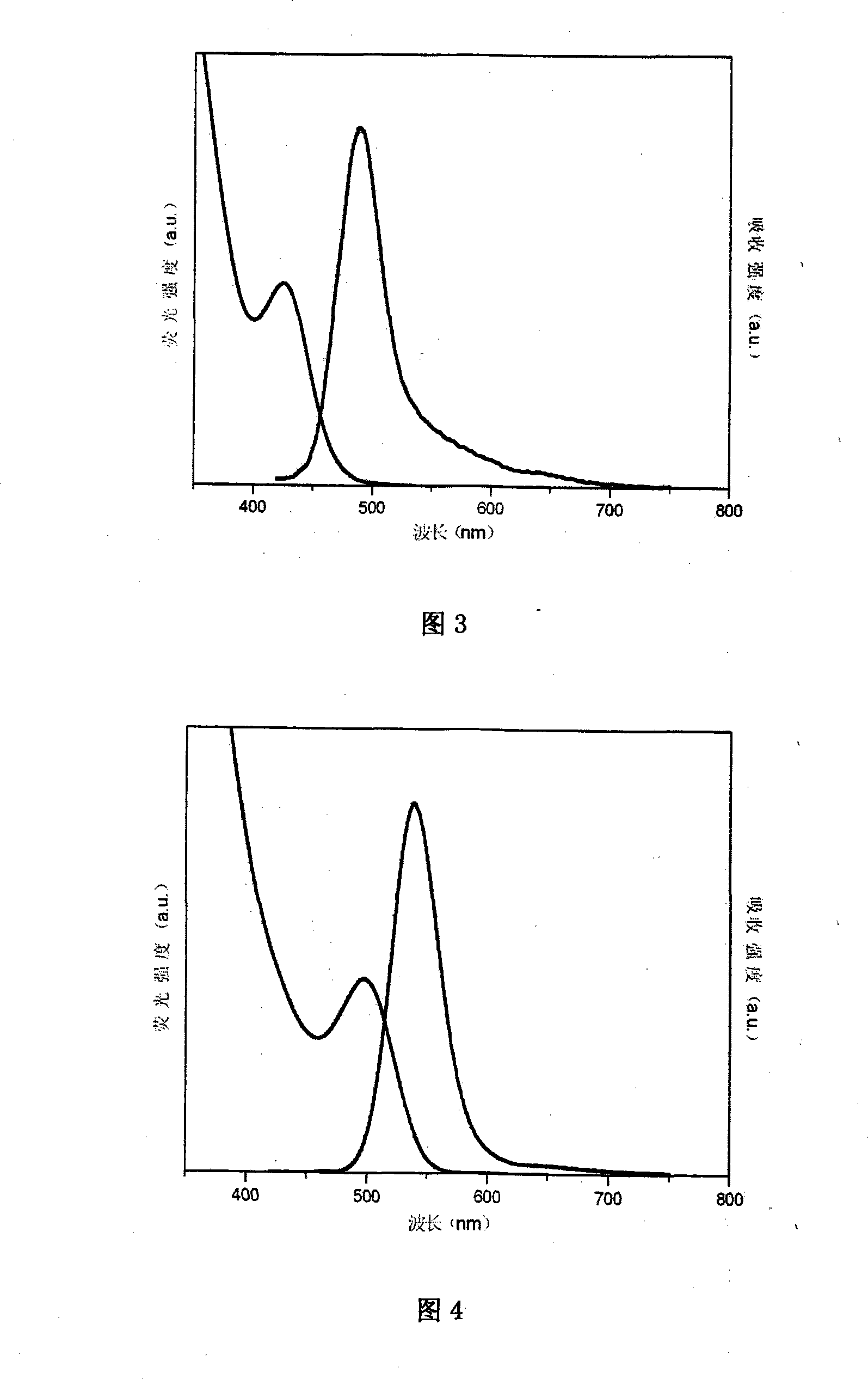

Water-phase synthesis method for water-soluble CdZnTe ternary quantum dots

A ternary quantum dot, water-soluble technology, applied in the synthesis field of nanotechnology, can solve problems such as performance impact, and achieve the effects of mild conditions, simple reaction steps and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (a) Synthetic sodium tellurium hydride NaHTe solution

[0026] Combine 20 mg Te powder and 13 mg sodium borohydride NaBH 4 The powders are mixed, put into a 5 ml sample bottle and 1 ml deionized water is added, and then the reaction bottle is placed at a temperature of 30°C for 2 hours to react to obtain a NaHTe solution.

[0027] (b) Preparation of Cd 2+ , Zn 2+ Precursor solution

[0028] Add 80 ml of deionized water to the three-necked flask, and then add 73 mg of CdCl 2 ·2.5H 2 O, 109 mg ZnCl 2 And 860 mg of glutathione to get (Cd 2+ +Zn 2+ ) / GSH molar ratio is 1:2.5, Cd 2+ / Zn 2+ Molar ratio 2:5, Cd 2+ Cd at a concentration of 4 mmol / L 2+ , Zn 2+ Precursor solution, and adjust the pH of the solution to 9.0, and then bubbling nitrogen into the solution for 30 minutes.

[0029] (c) Preparation of CdZnTe quantum dots by aqueous solution method

[0030] Inject the NaHTe prepared above into the Cd prepared above 2+ / Zn 2+ -GSH precursor solution, get (Cd 2+ +Zn 2+ ) / Te 2- T...

Embodiment 2

[0032] (a) Synthetic sodium tellurium hydride NaHTe solution

[0033] Combine 20 mg Te powder and 13 mg sodium borohydride NaBH 4 The powders are mixed, put into a 5 ml sample bottle and 1 ml deionized water is added, and then the reaction bottle is placed at a temperature of 30°C for 2 hours to react to obtain a NaHTe solution.

[0034] (b) Preparation of Cd 2+ , Zn 2+ Precursor solution

[0035] Add 57 ml of deionized water to the three-necked flask, and then add 52 mg of CdCl 2 ·2.5H2 O, 78 mg ZnCl 2 And 615 mg of glutathione to obtain (Cd 2+ +Zn 2+ ) / GSH molar ratio is 1:2.5, Cd 2+ / Zn 2+ Molar ratio 2:5, Cd 2+ Cd at a concentration of 4 mmol / L 2+ , Zn 2+ Precursor solution, and adjust the pH of the solution

[0036] 9.0, then let nitrogen gas through the solution for 30 minutes.

[0037] (c) Preparation of CdZnTe quantum dots by aqueous solution method

[0038] Inject the NaHTe prepared above into the Cd prepared above 2+ / Zn 2+ -GSH precursor solution, get (Cd 2+ +Zn 2+ ) / Te...

Embodiment 3

[0040] (a) Synthetic sodium tellurium hydride NaHTe solution

[0041] Combine 20 mg Te powder and 13 mg sodium borohydride NaBH 4 The powders are mixed, put into a 5 ml sample bottle and 1 ml deionized water is added, and then the reaction bottle is placed at a temperature of 30°C for 2 hours to react to obtain a NaHTe solution.

[0042] (b) Preparation of Cd 2+ , Zn 2+ Precursor solution

[0043] Add 115 ml of deionized water into the three-necked flask, and then add 104 mg of CdCl 2 ·2.5H 2 O, 46 mg ZnCl 2 And 615 mg of glutathione to obtain (Cd 2+ +Zn 2+ ) / GSH molar ratio is 1:2.5, Cd 2+ / Zn 2+ Molar ratio 4:3, Cd 2+ Cd at a concentration of 4 mmol / L 2+ , Zn 2+ Precursor solution, and adjust the pH of the solution to 9.0, and then bubbling nitrogen into the solution for 30 minutes.

[0044] (c) Preparation of CdZnTe quantum dots by aqueous solution method

[0045] Inject the NaHTe prepared above into the Cd prepared above 2+ / Zn 2+ -GSH precursor solution, get (Cd 2+ +Zn 2+ ) / T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com