Dazzling-proof hard coating material and high hardness hard coating film using same

A hard coating and anti-glare technology, applied in antifouling/underwater coatings, coatings, devices for coating liquid on the surface, etc., can solve the problem of hard coating films and hard coatings that cannot reach the display Solve problems such as curling at the end of the film and reduced visibility of the display, achieve high hardness, avoid curling, and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The above-mentioned silica particles used for the preparation of organic-inorganic silica particles are not particularly limited, but it is preferable to use colloidal silica sol dispersed in an organic solvent. As the organic solvent, methyl ethyl ketone and methyl isobutyl ketone among ketones, and isopropanol and methanol among alcohols can be used. Among them, in consideration of dispersibility and stability, methyl isobutyl ketone is preferably used.

[0037] Commercially available colloidal silica sol products include methyl ethyl ketone silica sol (MEK-ST, manufactured by Nissan Chemical Company, with an average particle size of 22nm and a silica content of 30%), silica powder Shaped particles (aerosil TT600, manufactured by aerosil, average particle size of 40nm), methyl isobutyl ketone silica sol (MIBK-ST, manufactured by Nissan Chemical Company, average particle size of 22nm, silica content of 30%) , Isopropanol silica sol (IPA-ST, manufactured by Nissan Chemical ...

Synthetic example 1

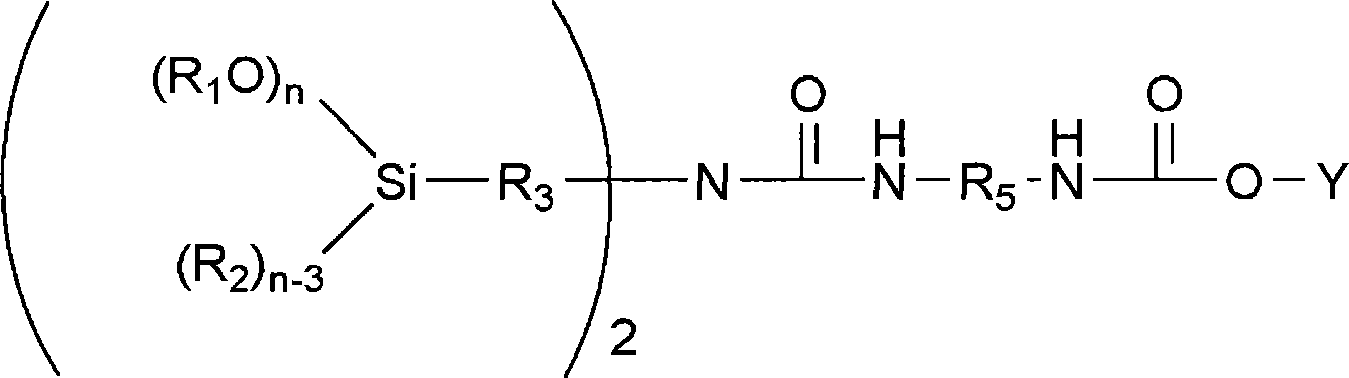

[0069] At a temperature of 0°C, slowly drop 20.6 parts by weight of isophorone diisocyanate into 14.2 parts by weight of bis[3-(trimethoxysilyl)propyl]amine and 0.2 parts by weight of isophorone diisocyanate over 1 hour. Dibutyl tin dimonthly silicate in solution. After the solution was stirred at 25°C for 30 minutes, 71.4 parts by weight of pentaerythritol triacrylate was slowly dropped in at 30°C over 1 hour. After dropping, the temperature was increased to 60°C, and stirring was performed for 3 hours.

[0070] The peak of the infrared absorption spectrum of the product is 1720 cm of [-N-(C=O)-NH-] -1 , The peak value of [-O-(C=O)-NH-] is 1660cm -1 .

Synthetic example 2

[0072] At a temperature of 0°C, slowly drop 20.6 parts by weight of isophorone diisocyanate into 14.2 parts by weight of bis[3-(trimethoxysilyl)propyl]amine and 0.2 parts by weight of isophorone diisocyanate over 1 hour. Dibutyl tin dimonthly silicate in solution. After the solution was stirred at 25°C for 30 minutes, 125.6 parts by weight of dipentaerythritol penta / hexaacrylate was slowly dropped at 30°C over 1 hour. After dropping, the temperature was raised to 60°C and stirring was performed for 3 hours.

[0073] The peak of the infrared absorption spectrum of the product is 1720 cm of [-N-(C=O)-NH-] -1 , The peak value of [-O-(C=O)-NH-] is 1660cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com