Water-soluble alcohol-soluble polyurethane and preparation method thereof

An alcohol-soluble, polyurethane technology, applied in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve problems such as inconvenient use, and achieve the effect of maintaining initial viscosity, fast curing, and convenient changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

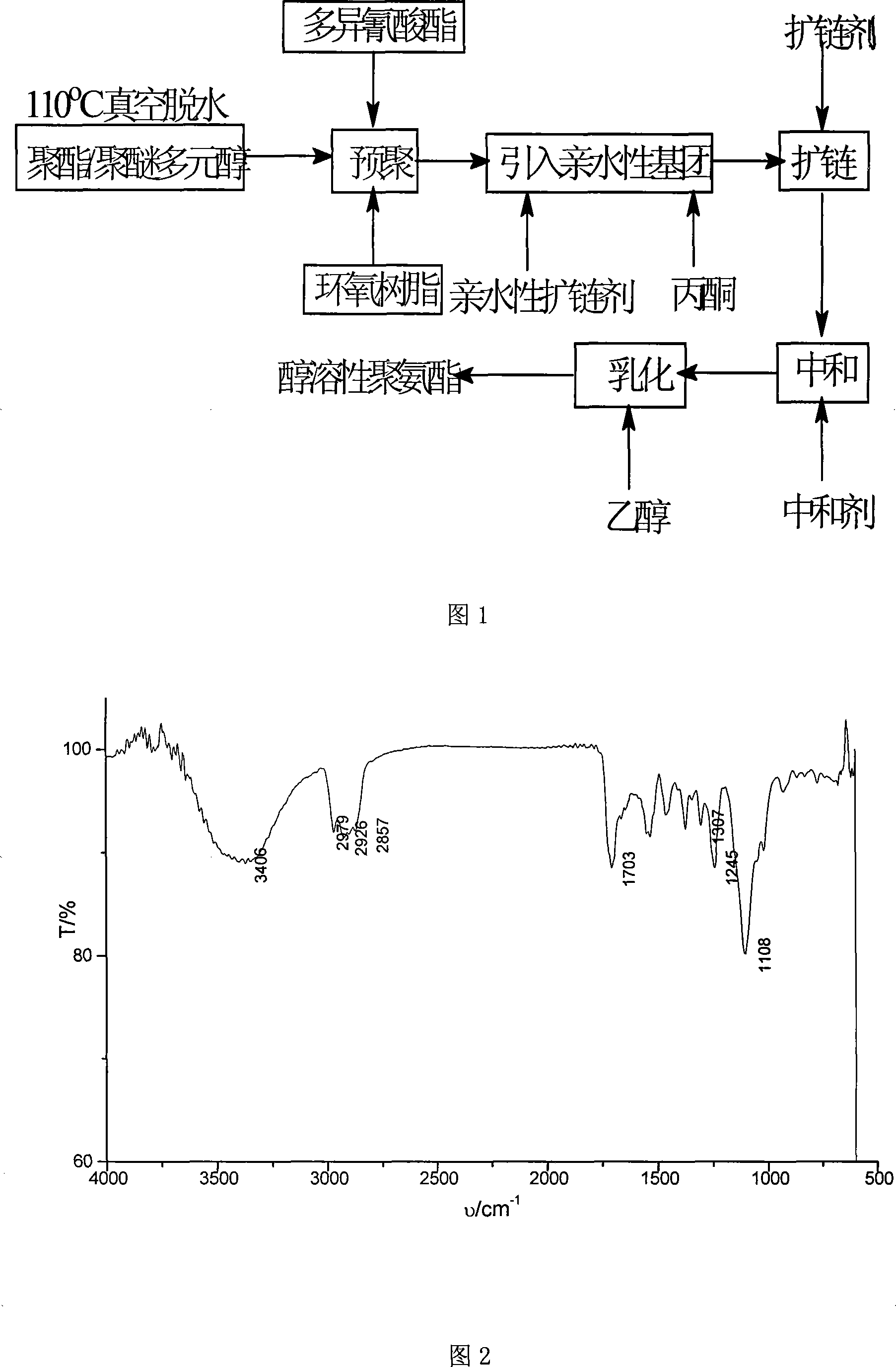

Method used

Image

Examples

Embodiment 1

[0038] in N 2 Under the protection of 110°C vacuum dehydration for 2h, 34.5g of polyoxypropylene diol (N-210), 30g of isophorone isocyanate (IPDI) and 2.5g of epoxy resin E-51 were weighed and placed in a 250ml three-necked flask In the middle, react at 85°C for 2 hours, then add 3.4g of dimethylolpropionic acid (DMPA) and 15ml of acetone, react at 70°C for 1 hour, finally add 8.34g of diethylene glycol (DEG), dilaurate dilaurate Two drops of butyltin (T-12), one drop of stannous octoate (T-9), react at 60°C for 4 hours, cool down to 45°C and discharge, which is the prepolymer; pour the prepolymer into the emulsification tank , at a rotating speed of 2500r / min, after neutralizing to pH 8 with 3.7ml of triethylamine, add 79.0g of ethanol and emulsify to obtain a white emulsion with a solid content of 50%. The obtained emulsion was distilled off under reduced pressure at 25°C and -0.08Mpa to remove the solvent acetone, and a white emulsion was prepared.

[0039] The test metho...

Embodiment 2

[0049] Under the protection of N2, weigh 34.5g of polybutylene adipate (PBA) after vacuum dehydration at 110°C for 2 hours, 30g of IPDI and 12.7g of epoxy resin E-5, put them in a 250ml three-necked flask, and react at 85°C After 2 hours, add 2.72g of DMPA, react at 70°C for 1 hour, finally add 8.88g of DEG, two drops of catalyst T-12 and one drop of T-9, 30ml of acetone, react at 60°C for 4.5 hours, cool down to 35°C and discharge , to obtain a prepolymer; pour the prepolymer into an emulsification tank, and at a speed of 2500r / min, use 3.0ml of triethylamine to neutralize to a pH of 7, add 77.5g of ethanol, and emulsify to obtain a solid Measure 50% white alcohol-soluble polyurethane emulsion. The obtained alcohol-soluble polyurethane emulsion was distilled off under reduced pressure at 25°C and -0.08Mpa to remove the solvent acetone, and the product was obtained.

[0050] From the comparative analysis of Examples 1 and 2, it can be seen that N-210 and PBA can be replaced b...

Embodiment 3

[0052] Under the protection of N2, weigh 34.5g of N-210, 30g of IPDI and 1.5g of E-51 resin after vacuum dehydration at 110°C for 2h, put them in a 250ml three-neck flask, react at 90°C for 1.5 hours, then add N-methyl Diethanolamine 3.3g, acetone 30ml, react at 65°C for 1 hour, finally add DEG 7.81g, TMP 0.7g, one drop of catalyst T-12, one drop of T-9, react at 60°C for 4.5 hours, cool down to 25°C and discharge , to obtain the prepolymer; pour the prepolymer into an emulsification tank, and at a speed of 2000r / min, neutralize it with 2.2g of glacial acetic acid to pH 6, add 40g of ethanol, emulsify, and obtain a solid content of 33 % white emulsion. Distill the resulting alcohol-soluble polyurethane emulsion at 25°C and -0.08Mpa under reduced pressure to remove the solvent acetone to obtain the product.

[0053] Since the TMP in this embodiment has 3 hydroxyl groups, it plays the role of crosslinking in this embodiment, so it can be replaced by a chain extender with a func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com