Low-formaldehyde high-strength adhesive and preparation method thereof

A high-strength, adhesive technology, applied in the direction of non-polymer adhesive additives, adhesives, adhesive additives, etc., can solve the problems of low bonding strength, excessive content, poor water resistance, etc., and achieve fast curing and high viscosity , good performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

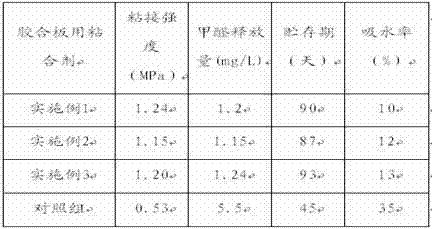

Examples

Embodiment 1

[0019] The technical scheme that present embodiment 1 adopts is:

[0020] A low-formaldehyde high-strength adhesive is characterized in that it is composed of the following raw materials by weight percentage: deionized water 65%, formaldehyde 4.5%, urea 10%, polyvinyl alcohol 10%, wheat flour 7%, acetic acid 0.2% , Sodium Hydroxide 0.25%, Curing Agent 0.1%, Tannin 0.05%.

[0021] A method for preparing a low-formaldehyde high-strength adhesive, comprising the following steps:

[0022] a) Add deionized water into the reaction pot according to the ratio, add polyvinyl alcohol when the temperature rises to 60°C, and then heat up to 85°C to completely dissolve the polyvinyl alcohol, add wheat flour and stir evenly after the dissolution is complete;

[0023] b) After the solution is cooled to 70°C, add acetic acid dropwise and stir for 20 minutes, then add formaldehyde for condensation reaction; when the temperature is lowered to 60°C, add sodium hydroxide to adjust the pH val...

Embodiment 2

[0026] The technical scheme that present embodiment 2 adopts is:

[0027] A low-formaldehyde high-strength adhesive, composed of the following raw materials by weight percentage: 75% deionized water, 3.8% formaldehyde, 5% urea, 10% polyvinyl alcohol, 5% wheat flour, 0.2% acetic acid, hydrogenated Sodium 0.12%, curing agent 0.1%, tannin 0.05%.

[0028] A method for preparing a low-formaldehyde high-strength adhesive, comprising the following steps:

[0029] a) Add deionized water into the reaction pot according to the ratio, add polyvinyl alcohol when the temperature rises to 65°C, and then heat up to 85°C to completely dissolve the polyvinyl alcohol, add wheat flour and stir evenly after the dissolution is complete;

[0030] b) After the solution is cooled to 70°C, add acetic acid dropwise and stir for 20 minutes, then add formaldehyde for condensation reaction; when the temperature is lowered to 65°C, add sodium hydroxide to adjust the pH value to 8.0;

[0031] c) Add u...

Embodiment 3

[0033] The technical scheme that present embodiment 3 adopts is:

[0034] A low-formaldehyde high-strength adhesive, which is composed of the following raw materials by weight percentage: 70% deionized water, 4.0% formaldehyde, 5% urea, 15% polyvinyl alcohol, 5% biomass, 0.15% acetic acid, hydrogen Sodium oxide 0.2%, curing agent 0.08%, tannin 0.03%.

[0035] A method for preparing a low-formaldehyde high-strength adhesive, comprising the following steps:

[0036] a) Add deionized water into the reaction pot according to the ratio, add polyvinyl alcohol when the temperature rises to 60°C, and then heat up to 85°C to completely dissolve the polyvinyl alcohol, add biomass after the dissolution is complete, and stir evenly;

[0037] b) After the solution is cooled to 75°C, add acetic acid dropwise and stir for 20 minutes, then add formaldehyde for condensation reaction; add sodium hydroxide to adjust the pH value to 7.0 when the temperature is lowered to 60°C;

[0038] c) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com