Casting method and mould for car air conditioning compressor slanting plate

A technology for automobile air conditioners and compressors, which is applied in the field of casting, can solve the problems of large fluctuations in the overall quality of castings, short mold life, low part yield, etc., and achieves high surface quality and dimensional accuracy, smooth flow, and reduced inclusion content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

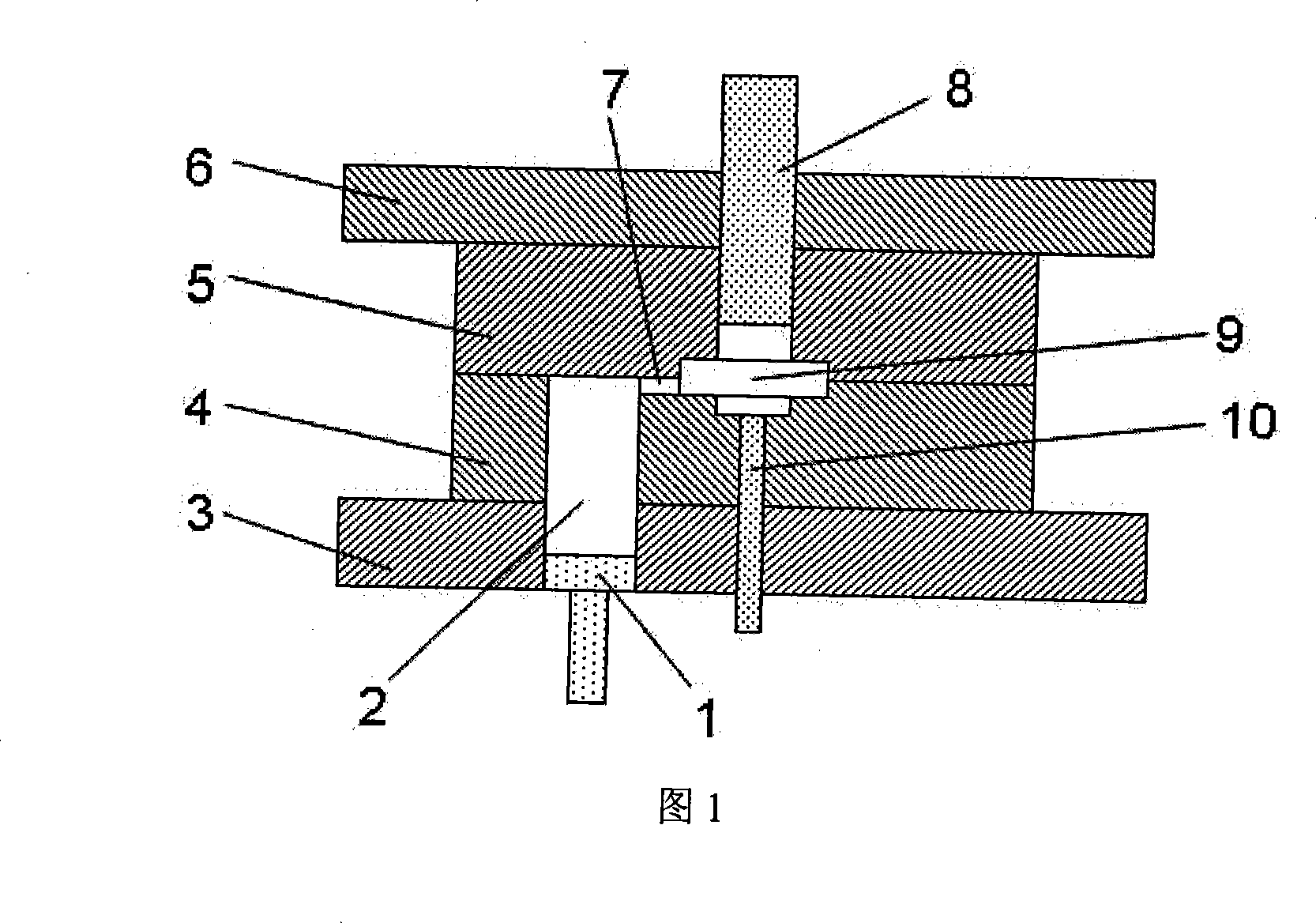

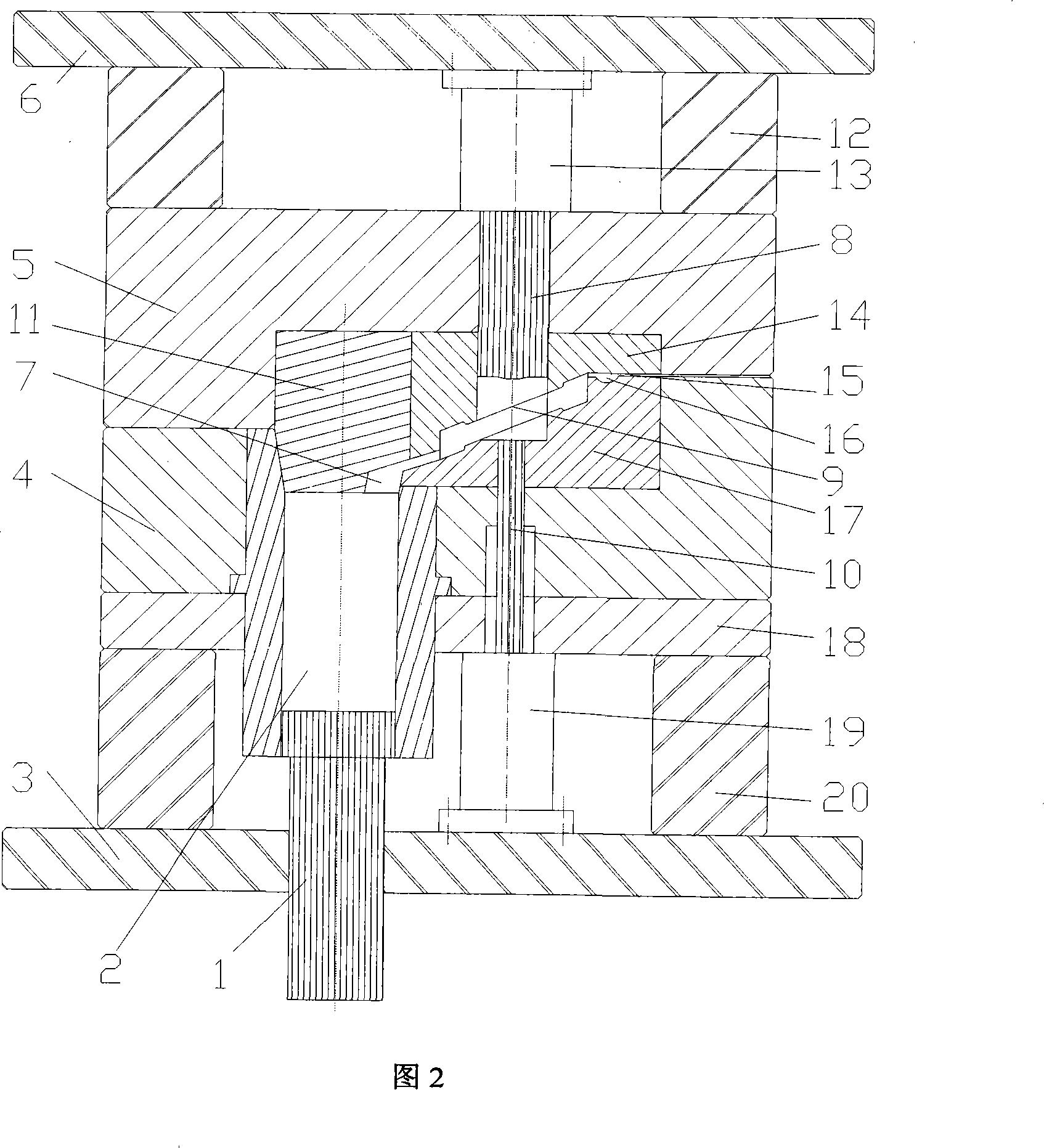

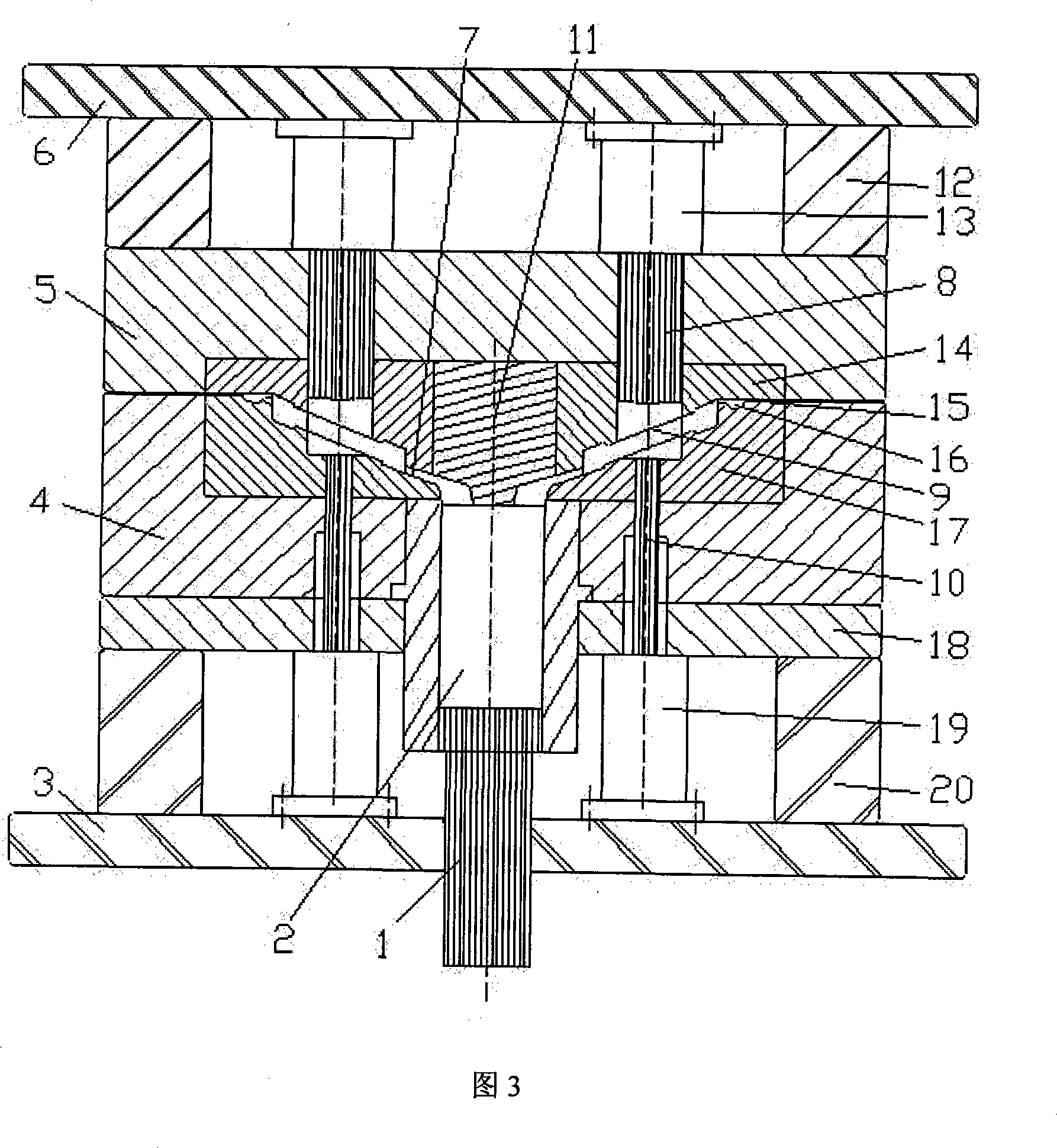

[0044] The aluminum alloy swash plate code-named CHD111-0202M is produced in one mold. The code of the swash plate varies from manufacturer to manufacturer, and this patent is not limited. The projection diameter of the swash plate is Φ71.3mm, the inclination angle of the swash plate is 17.5°, the vertical thickness of the outer circle is 12mm, and the height of the boss is 18.9mm. The swash plate material is A390. First, according to the A390 alloy composition, the required various raw materials such as pure aluminum ingot, crystalline silicon, electrolytic copper, pure magnesium, etc. are distributed and melted in the crucible resistance furnace. After the materials are completely melted, control to a predetermined temperature, add an appropriate amount of modifier, and scouring for 15 minutes, then slag slag is static, and the temperature is controlled at 790-810°C to be poured. The mold is preheated to 150-200°C, and the mold temperature is controlled at 250-300°C during norma...

Embodiment 2

[0046] One mold and two pieces of aluminum alloy swash plate with the swash plate code name CHD115-0202M, the code of the swash plate varies from manufacturer to manufacturer, and this patent is not limited. The projection diameter of the swash plate is Φ79.4mm, the inclination angle of the swash plate is 22°, the vertical thickness of the outer circle is 14.5mm, and the height of the boss is 22.4mm. The swash plate material is A390. Process the aluminum alloy liquid according to the melting process described in Example 1, close the mold after pouring, move the extrusion punch upward, and squeeze the melt into the cavity at 800mm / s; then move the pressure-holding punch down and apply a pressure of 80MPa At the top of the cavity, after maintaining the pressure for 8 seconds, apply a pressure of 120 MPa from the bottom of the cavity to press the feeding and pressurizing punch into the melt and hold it for 8s; then withdraw the feeding and pressurizing punch; After the runner is comp...

Embodiment 3

[0048] 1 One mold and two pieces of aluminum alloy swash plate with the swash plate code CHD121-0202M. The code of the swash plate varies from manufacturer to manufacturer, and this patent is not limited. The projection diameter of the swash plate is Φ79.4mm, the inclination angle of the swash plate is 17°, the vertical thickness of the outer circle is 14.0mm, and the height of the boss is 27.1mm. The swash plate material is A390. The aluminum alloy liquid was processed according to the melting process described in Example 1. After pouring, the mold was closed, the extrusion punch was moved up, and the melt was squeezed into the cavity at a flow rate of 680mm / s; then the pressure holding punch was moved down and applied to 80MPa After maintaining the pressure for 7 seconds, apply a pressure of 120 MPa from the bottom of the cavity to press the local feeding punch into the melt and keep it for 10 seconds; then withdraw the feeding punch; After the runner is completely solidified, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com