Great-width multi-hole lightweight core formwork and construction method thereof

A large-format, lightweight technology, used in building components, floors, buildings, etc., to prevent voids, increase overall strength, and ensure construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

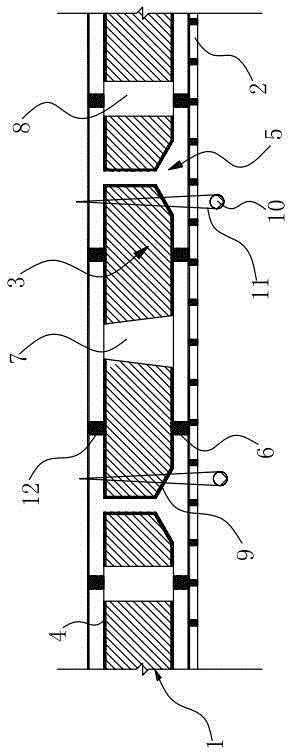

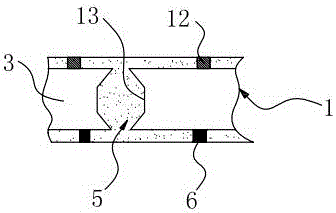

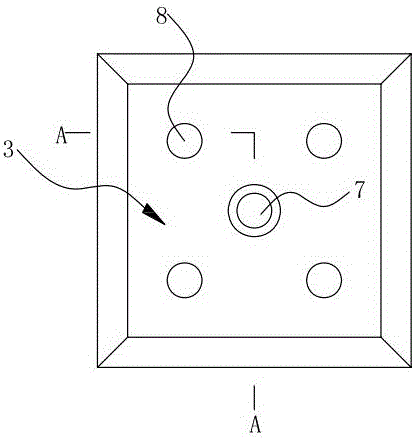

[0026] Combine below Attached picture The present invention will be described in further detail with reference to specific embodiments.

[0027] as shown in the picture 1 、 2 , 3, and 4, a large-format multi-hole lightweight mandrel includes a lightweight mandrel 3 pre-laid on the formwork 2 at the bottom of the concrete hollow floor 1 to be poured, and the light mandrel 3 is Foam material, the lightweight mandrel 3 is a square body, and the outer surface of the lightweight mandrel 3 is provided with a reinforcement layer 4 for increasing the overall strength of the lightweight mandrel 3 to prevent fracture during the pouring process, and the reinforcement layer 4 is an anti-crack grid Cloth, between the lightweight mandrel 3 and the bottom formwork 2 and between adjacent lightweight mandrels form a pouring area 5 for pouring concrete hollow floor 1, between the lightweight mandrel 3 and the bottom formwork 2 There is a supporting member 6 for supporting the lightweight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com