Technique for producing water-solubility function chitosan

A functional shell and water-soluble technology, which is applied in the production of water-soluble functional chitosan, can solve the problems of low water-soluble chitosan content, wide average molecular weight distribution, and limited application of physical methods, and achieve high-concentration pre-degradation, The effect of reducing side effects and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

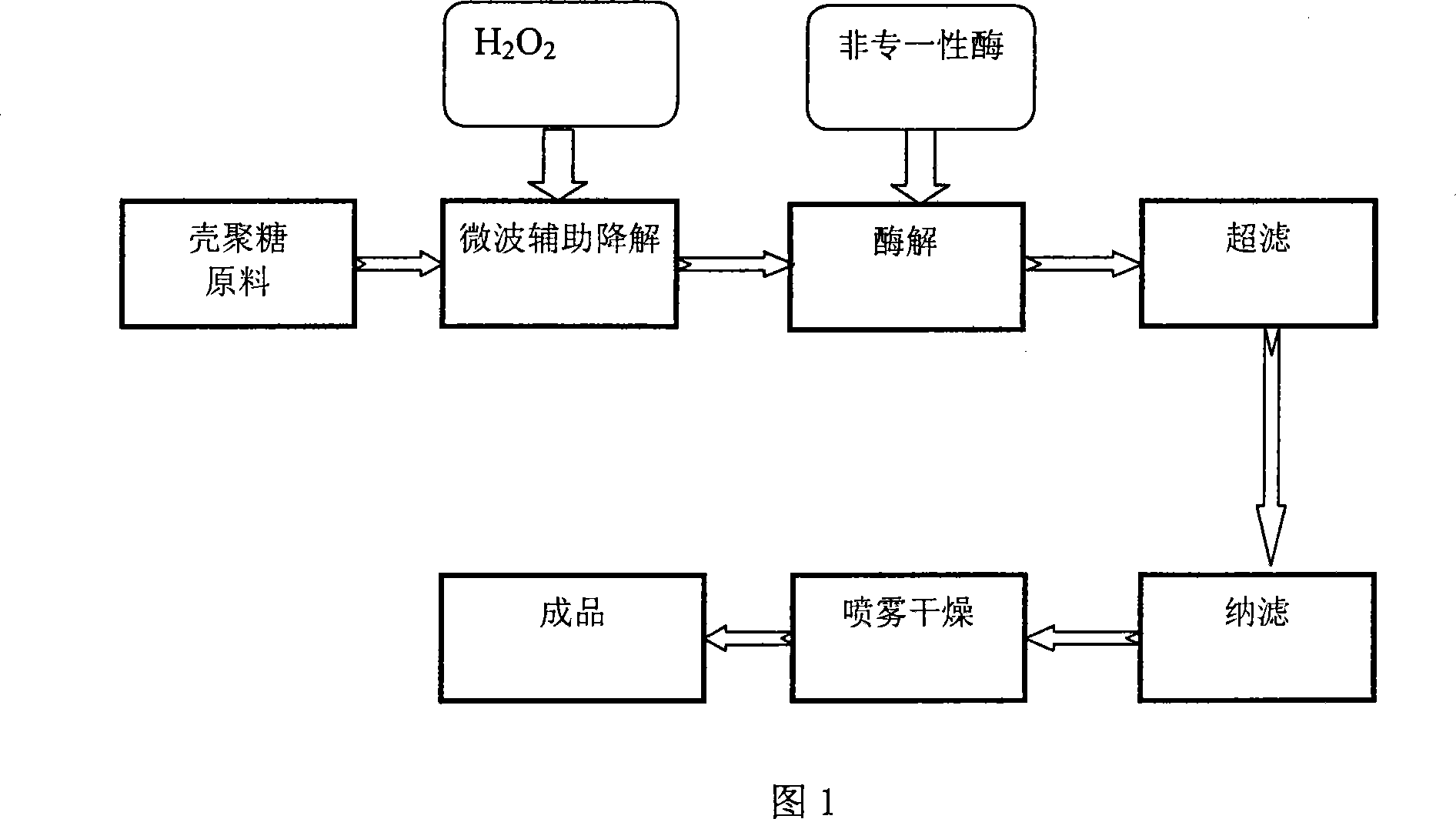

Image

Examples

Embodiment 1

[0033] Weigh 50g chitosan, then add 50mL H 2 o 2 (18% concentration) and mix thoroughly, adjust the microwave power to 450W, the microwave heating time is 3min, take out and cool naturally. Add water to prepare a 15% chitosan solution, adjust the pH to 5-6 with acetic acid, add 3% chitosan-quality cellulase, react in a water bath at 55°C for 3 hours, then rapidly heat to 80°C for 10 minutes to inactivate the enzyme. The enzymatic solution is filtered and centrifuged to remove the precipitate, and the supernatant is subjected to membrane ultrafiltration with a molecular weight cut-off of 5000D, the operating pressure is 1.0Mpa, and the operating temperature is 50±1°C. 1°C, remove salt and small molecular monosaccharides, concentrate and control the filtrate concentration to 25±2%, and spray dry to make a product, which can be directly dissolved in water to form a transparent solution.

Embodiment 2

[0035] Weigh 50g chitosan, then add 60mL H 2 o 2(18% concentration) and mix thoroughly, adjust the microwave power to 450W, the microwave heating time is 3min, take out and cool naturally. Add water to prepare a 20% chitosan solution, adjust the pH to 5-6 with hydrochloric acid, add 2% chitosan-quality lipase, react in a water bath at 45°C for 5 hours, then rapidly heat to 80°C to inactivate the enzyme for 10 minutes. The enzymatic solution is filtered and centrifuged to remove the precipitate, and the supernatant is subjected to membrane ultrafiltration with a molecular weight cut-off of 10000D, the operating pressure is 1.0Mpa, and the operating temperature is 50±1°C. 1°C, remove salt and small molecular monosaccharides, concentrate and control the filtrate concentration to 25±2%, and spray dry to make a product, which can be directly dissolved in water to form a transparent solution.

Embodiment 3

[0037] Weigh 50g chitosan, then add 50mL H 2 o 2 (18% concentration) and mix thoroughly, adjust the microwave power to 450W, the microwave heating time is 3min, take out and cool naturally. Add water to prepare a 15% chitosan solution, adjust the pH to 5-6 with acetic acid, add papain with 3% chitosan quality, react in a water bath at 60°C for 4 hours, then rapidly heat to 90°C to inactivate the enzyme for 10 minutes. The enzymatic solution is filtered and centrifuged to remove the precipitate, and the supernatant is subjected to membrane ultrafiltration with a molecular weight cut-off of 3000D, the operating pressure is 0.8Mpa, and the operating temperature is 55±1°C. 1°C, remove salt and small molecular monosaccharides, concentrate and control the filtrate concentration to 25±2%, and spray dry to make a product, which can be directly dissolved in water to form a transparent solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com