Method for synthesizing high specific surface area ordered mesoporous metal oxide by using hard template agent

A high specific surface area, hard template technology, applied in the direction of rare earth metal compounds, chromium oxide/hydrate, chemical instruments and methods, etc., can solve the problems of poor pore structure regularity, easy channel collapse, and poor universality of the method. Achieve the effects of narrow pore size distribution, low preparation cost and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

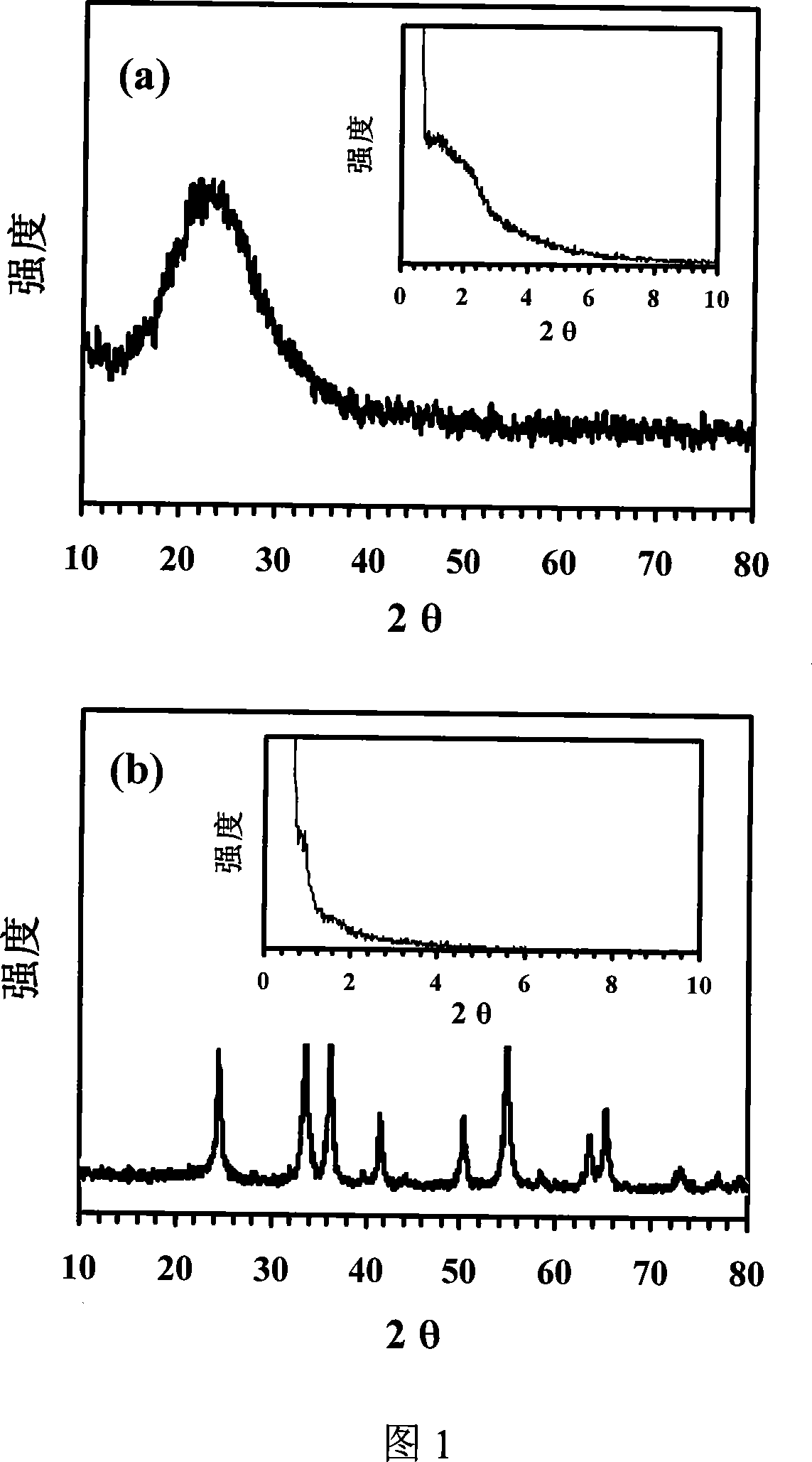

Embodiment 1

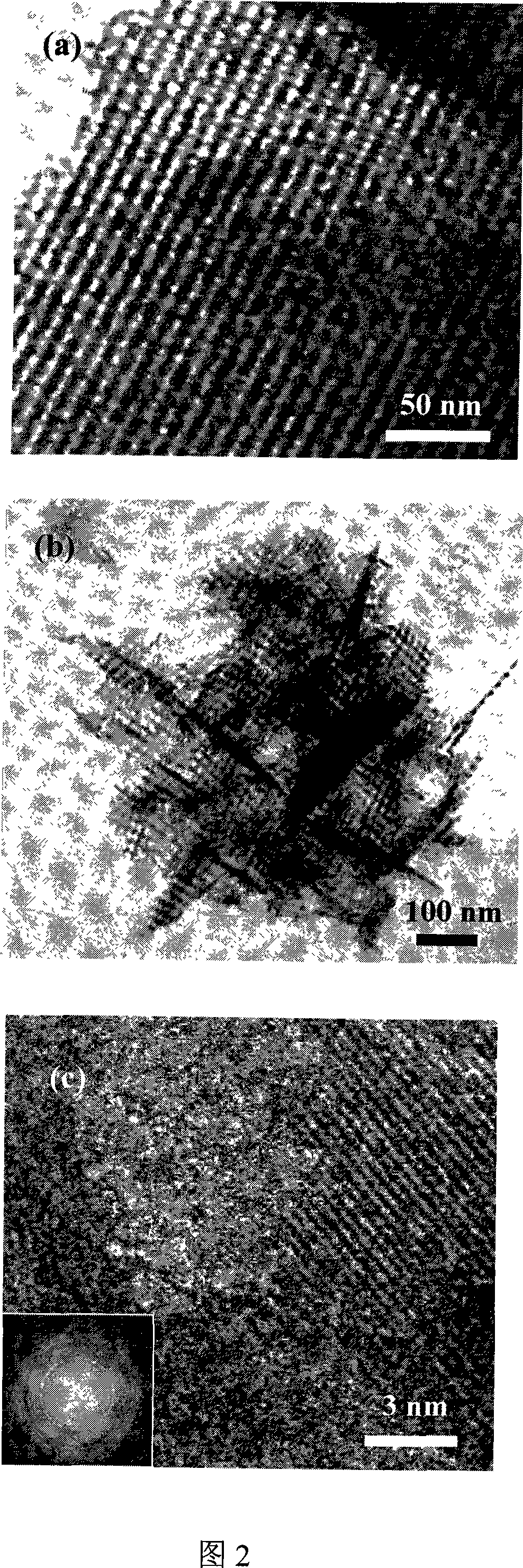

[0020] Embodiment 1: At room temperature, in 100mL 0.5mol / L hydrochloric acid solution, add 2.7g triblock copolymer (EO) 20 (PO) 70 (EO) 20 (Pluronic P123), stir until dissolved, slowly (2°C / min) heat up to 35°C, add 2.8g n-butanol while stirring, and keep stirring at 35°C for 1 hour, then add 5.8g orthosilicon to the above solution Ethyl acetate (the molar ratio of each substance is: ethyl orthosilicate: triblock copolymer (EO) 20 (PO) 70 (EO) 20 : hydrochloric acid: deionized water: n-butanol=1: 0.017: 1.83: 195: 1.31), keep stirring at 35°C for 24 hours, transfer to an autoclave and heat at 100°C for 24 hours, filter, deionized water and ethanol After washing, it was dried at 60°C, and then the temperature was programmed in a muffle furnace (1°C / min) to 550°C and burned at 550°C for 4 hours to obtain a cubic phase mesoporous silica (KIT-6) white powder. The specific surface area of the resulting KIT-6 is 780m 2 / g, the average pore diameter is 3nm.

[0021] Add 1.0...

Embodiment 2

[0022] Example 2: The synthesis of hard template KIT-6 is the same as that in Example 1. Add 0.5g of ammonium dichromate to 10mL of 50wt% ethanol solution, stir to dissolve, add 0.5g of KIT-6 white powder to the above solution, ultrasonically disperse for 100 minutes, and then place the mixture at 40°C under magnetic stirring Evaporated until the obtained solid was heated to 400°C at a rate of 1°C / min in a nitrogen atmosphere (nitrogen flow rate of 30mL / min) and kept at 400°C for 4 hours, and finally washed with 10wt% HF solution to remove the silicon template. After drying at 60°C for 24 hours, the mesoporous polycrystalline chromium oxide powder was obtained with a specific surface area of 167m 2 / g, the average pore diameter is 7nm.

Embodiment 3

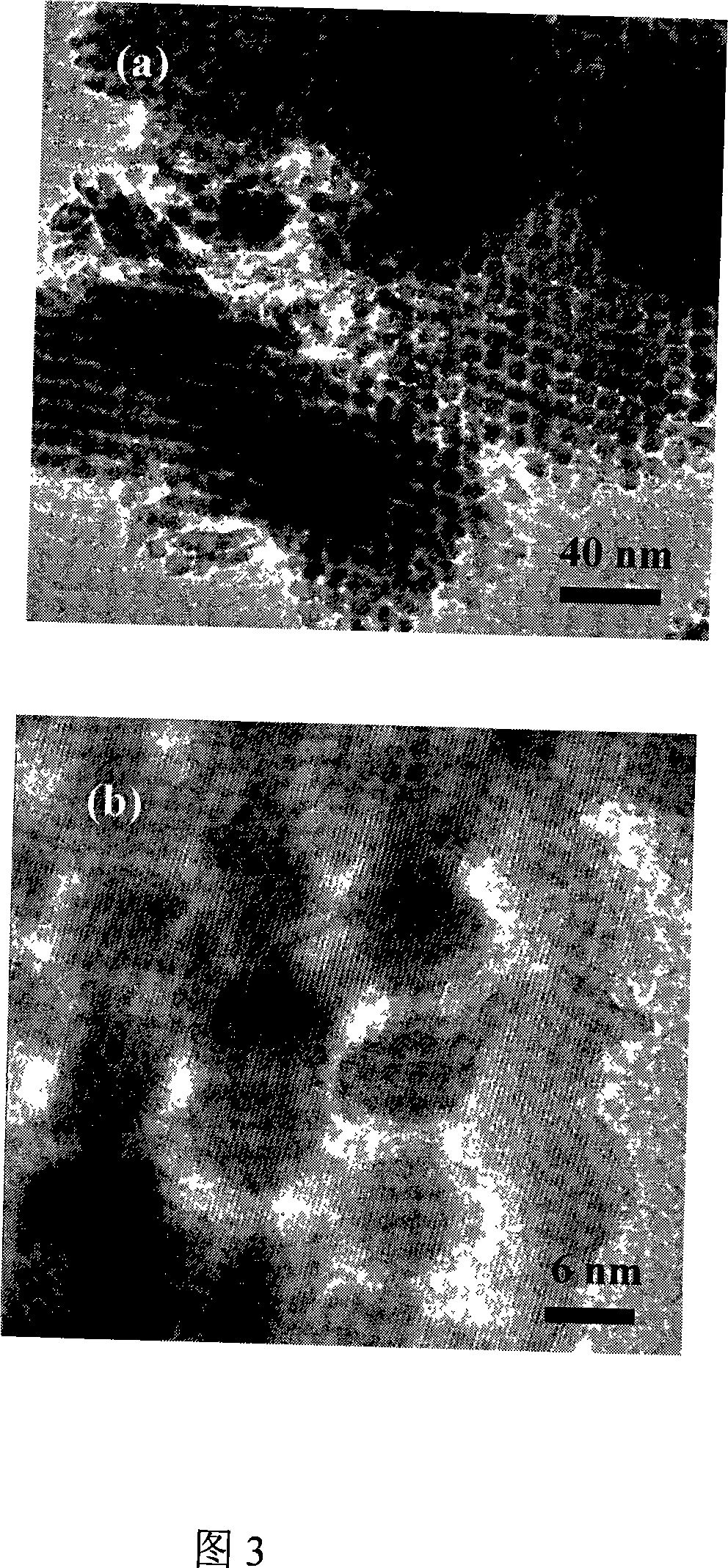

[0023]Example 3: The synthesis of hard template KIT-6 is the same as that in Example 1. Add 1.2g of chromium oxalate to 10mL of absolute ethanol, stir to dissolve, add 0.5g of KIT-6 white powder to the above solution, ultrasonically disperse for 100 minutes, then evaporate the mixture to dryness at 40°C under magnetic stirring, The obtained solid was heated up to 400° C. at a rate of 1° C. / min in a nitrogen atmosphere (nitrogen flow rate of 30 mL / min) and kept at 400° C. for 4 hours. Finally, the silicon template was removed by washing with 10 wt % HF solution, and then at 60 After drying at ℃ for 24 hours, the mesoporous polycrystalline chromium oxide powder is obtained, and its specific surface area is 125m 2 / g, the average pore diameter is 15nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com