Method of making electric heater socket connector plug

A manufacturing method and electric heater technology, which are applied in the manufacturing of contacts and other directions, can solve the problems of complex process, low bonding strength of metallized layers, and high manufacturing cost, and achieve the effects of high bonding strength, shortening maintenance time, and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

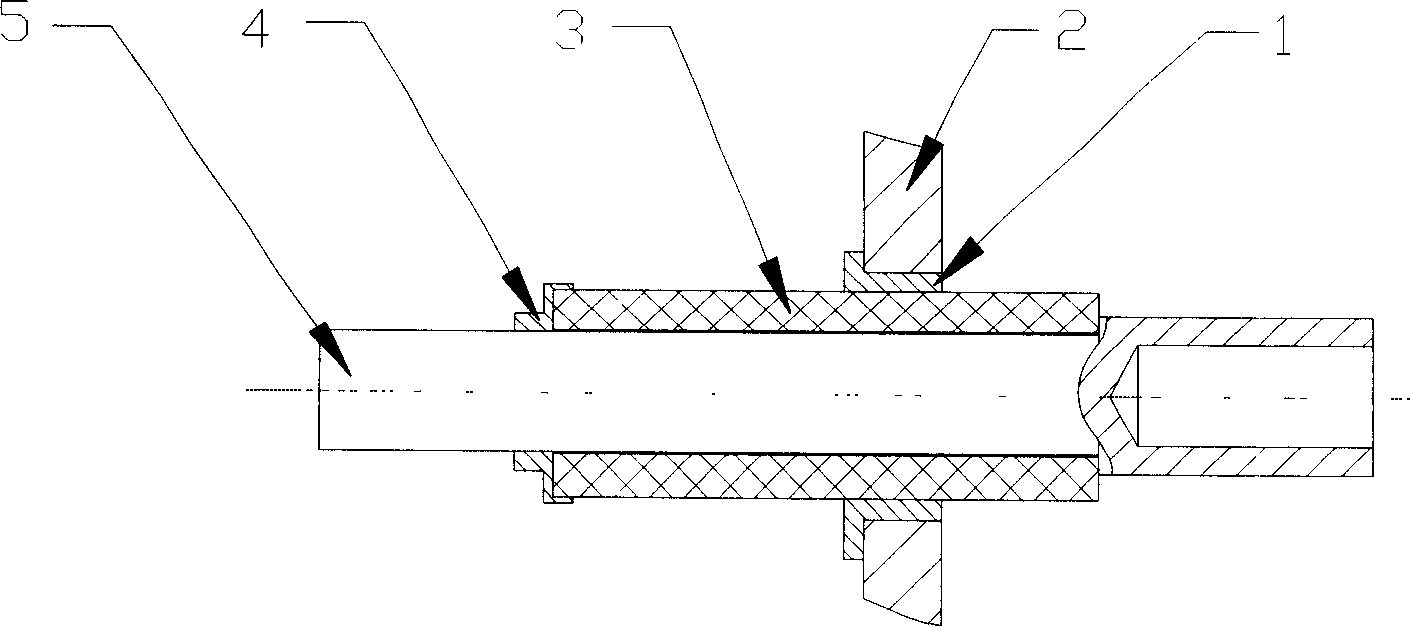

[0039] like figure 1 As shown, a ceramic metallization sealing method is used to manufacture electric heater connectors, which can be used on tubular electric heaters in special environments such as chemical industry. Using ceramic metallization and sealing method technology, by adjusting the slurry formula of metal molybdenum and manganese, improving the sintering method and sealing method, and using the characteristics of corrosion resistance and good electrical insulation of ceramic materials, this connector is made It has the characteristics of corrosion resistance, temperature resistance, radiation resistance, air tightness and electrical insulation performance, which can increase the service life of the electric heater and reduce the product cost. The specific method steps are as follows:

[0040] (1) Preparation of metallization paste

[0041] Get 500 grams of 300-order molybdenum powder, 500 grams of 300-order manganese powder, and 500 grams of 300-order additive, an...

Embodiment 2

[0052] (1) Preparation of metallization paste

[0053] Get 500 grams of 300-order molybdenum powder, 500 grams of 300-order manganese powder, and 500 grams of 300-order additive, and ball mill them in a ball mill for 12 hours respectively before use. Pour 285g of ethyl acetate into a 500ml ground-mouth bottle, and add 15 grams of nitrocellulose and stir. After 24 hours, the nitrocellulose is completely dissolved and set aside. Take by weighing 250 grams of molybdenum powders, 125 grams of manganese powders, 100 grams of additives and 25 grams of solvents from the ground material, and ball mill and mix them for 5 hours in a ball mill jar. Thereafter, the metallization paste was poured into glassware for later use.

[0055] Put the cleaned and dried ceramic tube on the rotating device, paint the required parts of the ceramic tube by hand according to the drawings, and let it dry after coating. The metallization paste coating thickness is 0.05mm.

...

Embodiment 3

[0066] (1) Preparation of metallization slurry:

[0067] Get 500 grams of 300-order molybdenum powder, 500 grams of 300-order manganese powder, and 500 grams of 300-order additive, and ball mill them in a ball mill for 12 hours respectively before use. Pour 270g of ethyl acetate into a 500ml grinding bottle, and add 30g of nitrocellulose and stir. After 24 hours, the nitrocellulose is completely dissolved and set aside. Take by weighing 325 grams of molybdenum powders, 75 grams of manganese powders, 75 grams of additives and 25 grams of solvents from the ground material, and ball mill and mix for 2 hours in a ball mill tank. Thereafter, the metallization paste was poured into glassware for later use.

[0068] (2) Slurry coating

[0069] Put the cleaned and dried ceramic tube on the rotating device, paint the required parts of the ceramic tube by hand according to the drawings, and let it dry after coating. The metallization paste coating thickness is 0.05mm.

[0070] (3) M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com