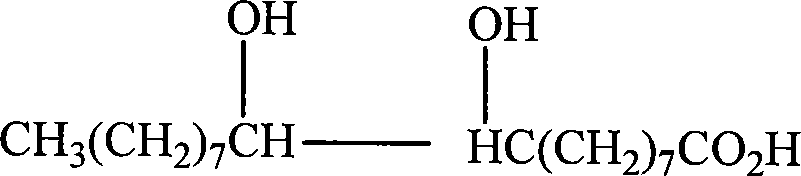

Method for preparing 9,10-dihydroxystearic acid and its methyl by hydrogen dioxide oxidation process

A technology of dihydroxystearic acid and hydrogen peroxide, which is applied in the field of preparation 9, can solve the problems of no separation and purification, and achieve the effects of environmental friendliness, greening, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] With 50g oleic acid (mass percentage is 75%, molar ratio is 0.1329mol), the mixture of 25g (0.5435mol) formic acid is placed in three-necked reaction flask, is that 20% hydrogen peroxide 50ml is added dropwise at room temperature, is warming up to 30 ℃ oxidation;

[0035] React 2 hours after hydrogen peroxide is added dropwise;

[0036] Carry out underpressure distillation recovery solvent after reaction finishes, and reaction mixture adopts organic solvent ethyl acetate recrystallization;

[0037] After drying the crystallized product, a 9,10-dihydroxystearic acid product with a yield of 90% and a purity of 92.6% can be obtained;

[0038] The acid value of the obtained 9,10-dihydroxystearic acid product is 185, the iodine value is 0, and the melting point is 89-93°C;

[0039] Add the 7g calcium oxide of raw material weight in the remaining formic acid aqueous solution after reaction, obtain product calcium formate reclaiming through routine method;

[0040] Add 3 ti...

Embodiment 2

[0042] A mixture of 53g oleic acid (75% by mass, 0.1409mol molar ratio) and 50g (1.087mol) formic acid was placed in a three-necked reaction flask, 80ml of 25% hydrogen peroxide was added dropwise at room temperature, and the temperature was raised to 40°C for oxidation ;

[0043] After the hydrogen peroxide has been added dropwise, react for 4 hours;

[0044] After the reaction is finished, the solvent is recovered by distillation under reduced pressure, and the reaction mixture is recrystallized with the organic solvent diethyl ether;

[0045] The 9,10-dihydroxystearic acid product with a yield of 94% and a purity of 93.6% can be obtained after drying the crystallized product;

[0046] The acid value of the obtained 9,10-dihydroxystearic acid product is 173, the iodine value is 0, and the melting point is 90-94°C;

[0047] Add the 10g calcium carbonate of raw material weight in the formic acid aqueous solution that remains after reaction, obtain product calcium formate recov...

Embodiment 3

[0050] With 55g oleic acid (mass percentage is 75%, molar ratio is 0.1463mol), the mixture of 110g (2.3914mol) formic acid is placed in three-necked reaction flask, and concentration is 30% hydrogen peroxide 100m at room temperature, is warming up to 45 ℃l oxidation;

[0051] React 5 hours after hydrogen peroxide has been added dropwise;

[0052] After the reaction is finished, the solvent is recovered by distillation under reduced pressure, and the reaction mixture is recrystallized from ethyl acetoacetate;

[0053] The 9,10-dihydroxystearic acid product with a yield of 94% and a purity of 95% can be obtained after drying the crystallized product;

[0054] The acid value of the obtained 9,10-dihydroxystearic acid product is 171, the iodine value is 0, and the melting point is 94-96°C;

[0055] Add the 10g calcium oxide of raw material weight in the formic acid aqueous solution that remains after reaction, obtain product calcium formate reclaim through routine method;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com