Production technology for wood-plastic water-proof outdoor floor and products produced thereby

A production process and waterproof room technology, applied in the field of wood product production process, can solve the problems of easy cracking of floor tiles, poor processability, and non-reusable wooden floors, etc., and achieve good secondary processing performance, good impact resistance, and environmental protection ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

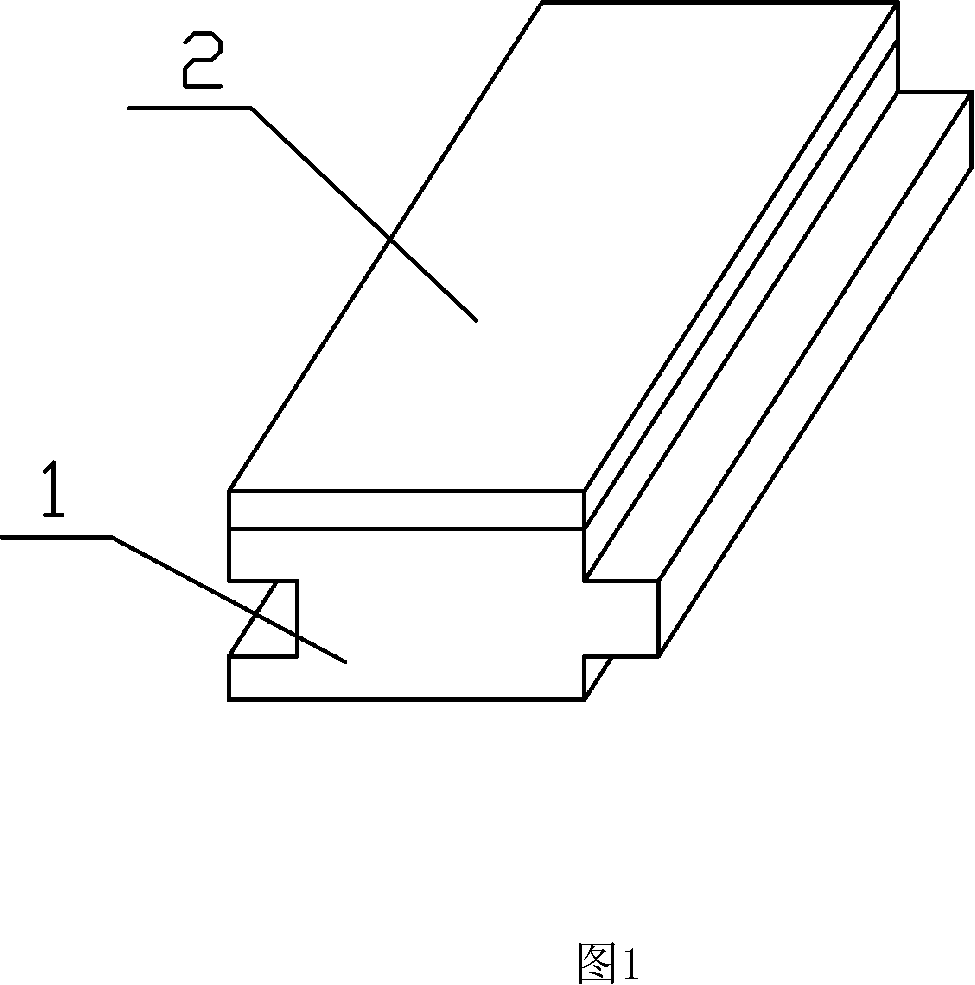

[0018] Embodiment 1 of the present invention: the production process of wood-plastic waterproof outdoor flooring, which includes crushing wood into wood powder with a diameter of 250 mesh, and mixing it with PP plastic powder with a diameter of 370 mesh; mixing 35 parts of wood powder with 65 parts of PP powder , and add 20 parts of CaCO3 (added in PP as reinforcement, toughening, filling and flame retardancy), and 5 parts of plasticizer (DOP), and carry out blending modification in a blender to obtain a mixed powder; The mixed powder is added to the extruder and extruded. The extrusion temperature is 190°C, the extrusion speed is 150 rpm, and the die pressure is 6MPa; extruded through the die to form a wood-plastic substrate with a layer of wood-like surface The profile, its imitation wood surface, can be formed during extrusion by engraving prints on the upper die head; it can also be formed by molding after extrusion from the die head. The profiles are cooled and shaped, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com