Vacuum tube direct-insertion type solar hot water system

A solar hot water and vacuum tube technology, applied in the field of solar energy utilization systems, can solve the problems of uncontrollable water temperature, easy to explode tubes, low water outlet pressure, etc., achieve the best heat exchange effect and use effect, improve antifreeze performance, ensure water effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

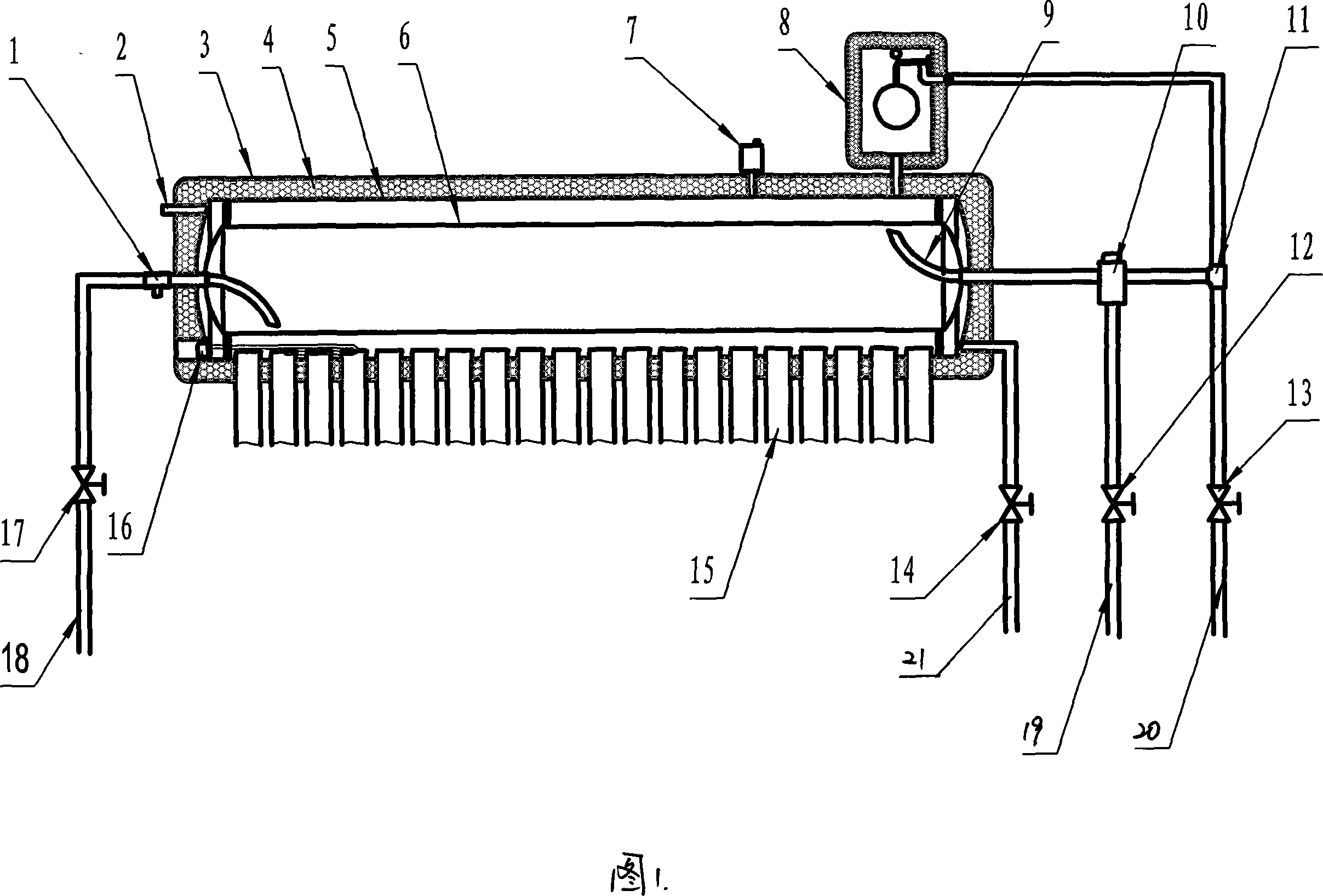

[0011] As shown in the figure: 1. Safety valve, 2. Reserved interface, 3. Water tank shell, 4. Insulation layer, 5. Hot water storage tank, 6. Pressure liner, 7. Air valve, 8. Automatic Compensation device, 9. Hot water outlet pipe, 10. Thermostatic valve, 11. Tap water tee, 12. Water valve, 13. Tap water ball valve (normally open), 14. Ball valve (normally closed, spare), 15. Vacuum tube, 16 . Electric heater, 17. Maintenance ball valve (normally open), 18. Cold water pipe, 19. Water pipe, 20. Tap water pipe, 21. Spare hot water pipe.

[0012] The vacuum tube in-line pressurized solar water heating system includes a hot water storage tank 5 and a heat-absorbing vacuum tube 15 . The hot water storage tank 5 is provided with an air valve 7 and a reserved interface 2 . The hot water storage tank 5 is provided with an electric auxiliary heating device 16 and a heat-exchanging pressure-bearing liner 6 , and the heat-exchanging pressure-bearing liner 6 is arranged concentrically wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com