Gallium nitride radical heterojunction field effect transistor structure and method for making the same

A heterojunction field effect, gallium nitride-based technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as increased deep-level defects, reduced mobility, and increased interface roughness. Achieve the effects of improving the two-dimensional electron gas mobility, improving the crystal quality, and reducing the defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

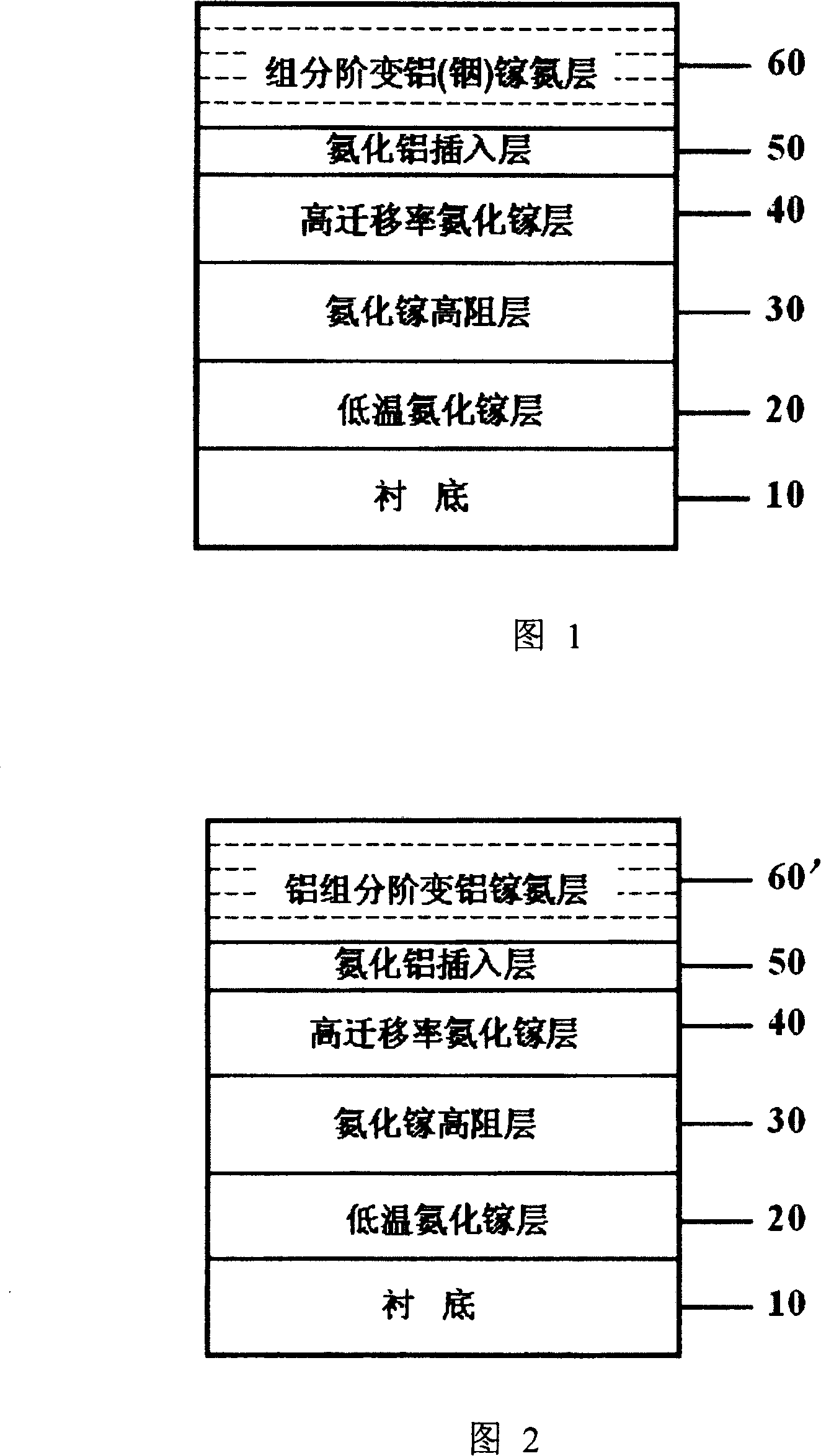

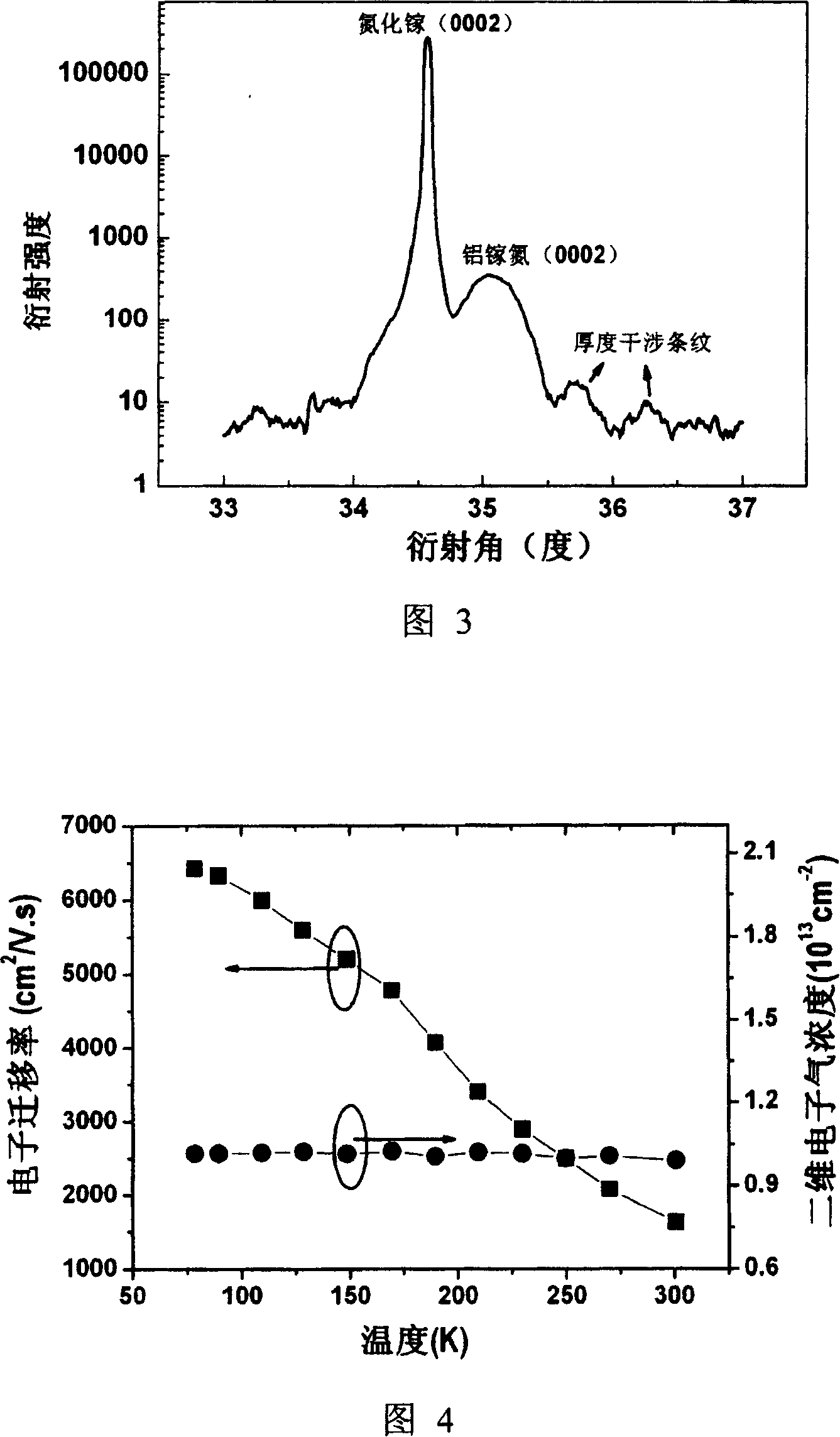

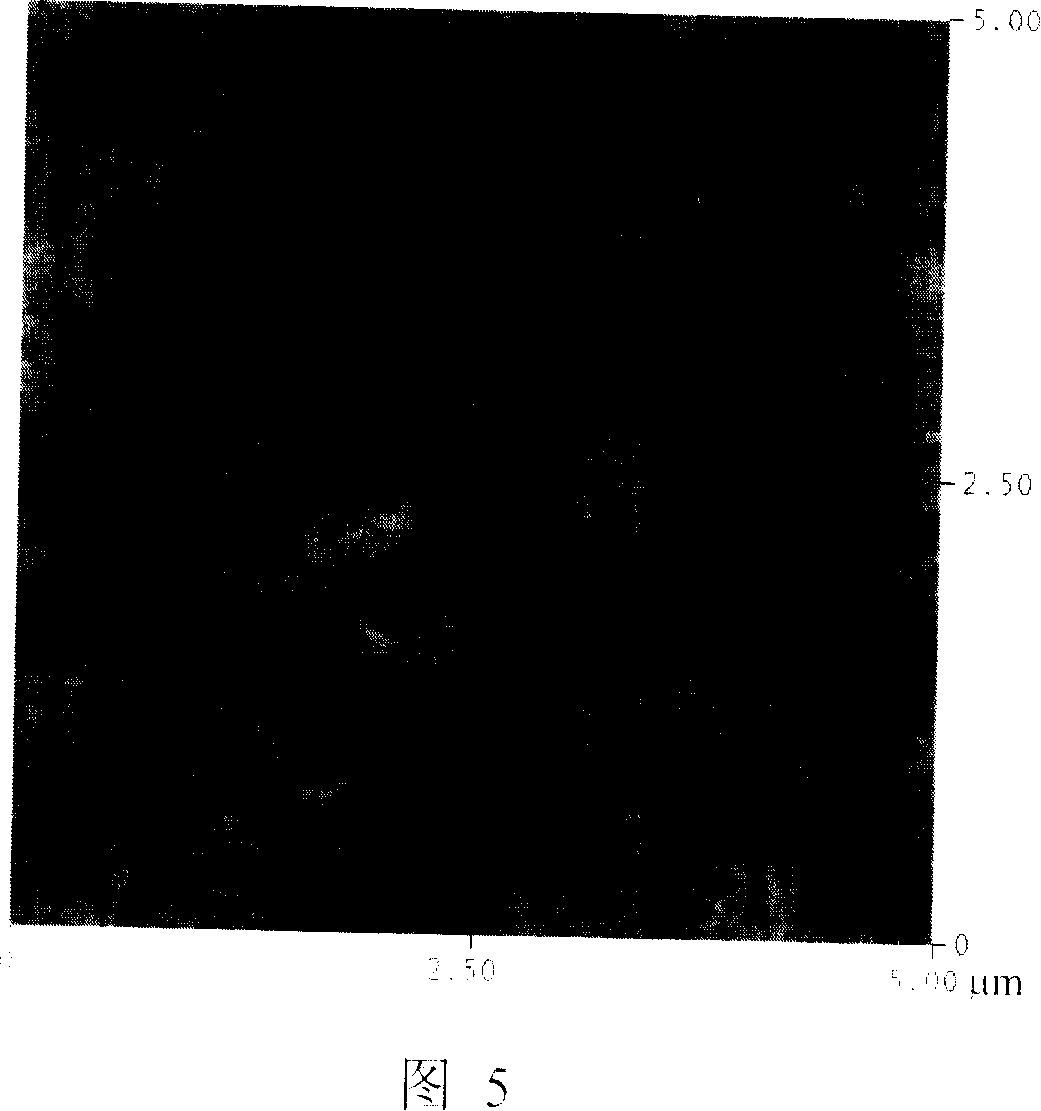

[0060] The key of the present invention is that the structure adopts a unique composition step change aluminum (indium) gallium nitrogen barrier layer structure (along the growth direction, the energy band level changes from high to low, and maintains a large energy band at the heterojunction interface. The band step is discontinuous, and then the energy band step gradually decreases to the surface of the barrier layer), a new type of high-mobility gallium nitride thin layer is used as the channel layer, and the gallium nitride channel layer and aluminum (indium) gallium nitride A thin layer of aluminum nitride insertion layer is introduced between the barrier layers. By precisely controlling the growth conditions, such as temperature, pressure, and V / III ratio, the stress caused by lattice mismatch and thermal expansion mismatch is effectively relieved, and the nitrogen The defect density of the GaN epitaxial layer improves the crystal quality of the channel layer, and the GaN...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Room temperature resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com