Front vibration absorber of motor tricycle

A technology for three-wheeled motorcycles and front shock absorbers, which can be used in bicycle accessories, steering mechanisms, transportation and packaging, etc., and can solve problems such as high cost, complicated processing, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

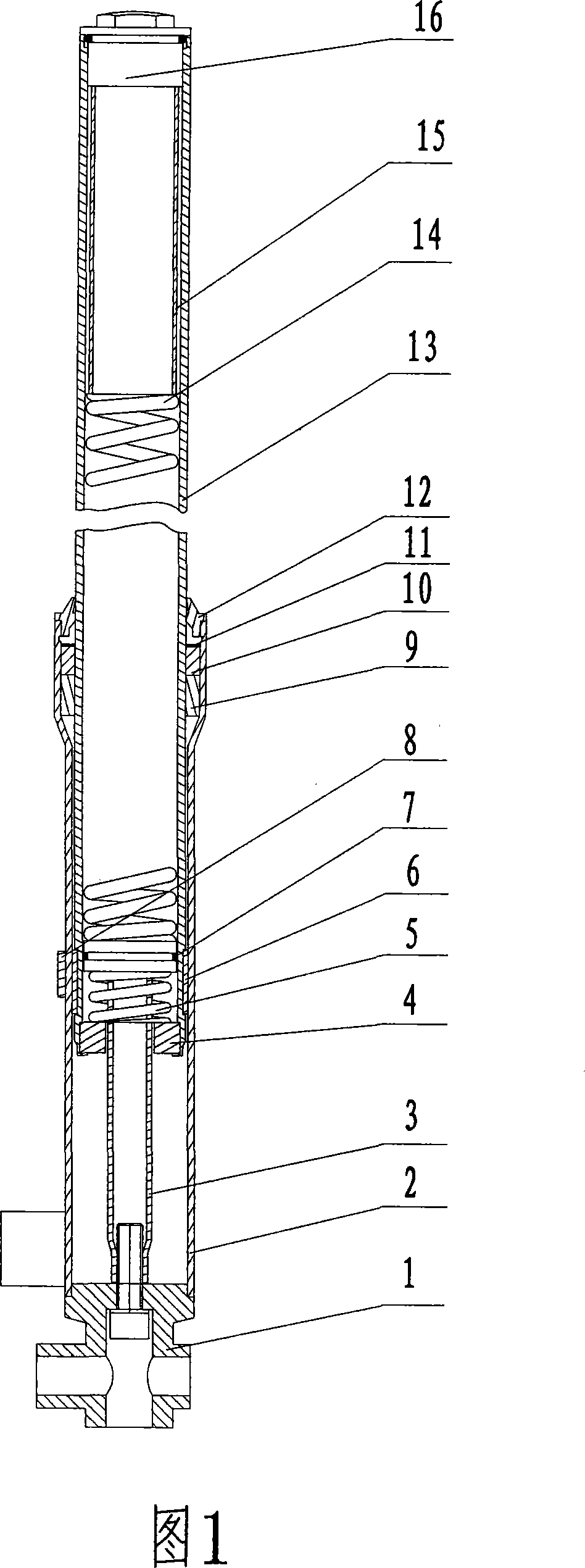

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0010] As shown in Figure 1, the shock absorber 2 is formed by one-time cold drawing of high-precision cold-drawn steel pipe or cold-drawn steel pipe, and its bottom end is welded with a joint 1. The joint 1 is a steel casting or forging formed by paraffin precision casting. The fender support 8 is welded on the shock tube 2, and the fender support 8 is a steel casting or forging formed by paraffin precision casting; There is a composite sleeve 6, the composite sleeve 6 is a copper-based composite sleeve or an oil-free bearing or a powder metallurgy sleeve, and an expansion joint is provided on the composite sleeve, which is convenient for installation and replacement, and avoids direct friction between the inner wall of the shock-absorbing cylinder 2 and the outer wall of the shock-absorbing column 13; Fix the guide sleeve 4 in the inner cavit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com