Tumour interposition suppository norcantharidin-alginic acid/poly-acid anhydride control-release microsphere

A technology of demethylcantharidin and alginic acid, applied in medical science, surgery, etc., can solve the problems of large blood vessel irritation, toxic and side effects, unstable drug release, etc., and achieve stable drug release, simple preparation process, and ball formation good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of norcantharidin-alginic acid / polyanhydride microspheres

[0026] PLGA and norcantharidin were simultaneously dissolved in ethyl acetate, and then emulsified with sodium alginate solution to form colostrum. The colostrum is emulsified with n-octane at a high speed, adding an emulsifier to adjust the HLB value to form double emulsion, then adding 15% calcium chloride solution and stirring for 10 minutes to fully cross-link calcium ions and alginic acid, and solidify to form calcium alginate. Filter under reduced pressure, rinse with distilled water several times, and dry in a 37°C oven overnight under reduced pressure. Sieve and pack according to particle size, 60 Co irradiation sterilization, obtains the drug microsphere of the present invention.

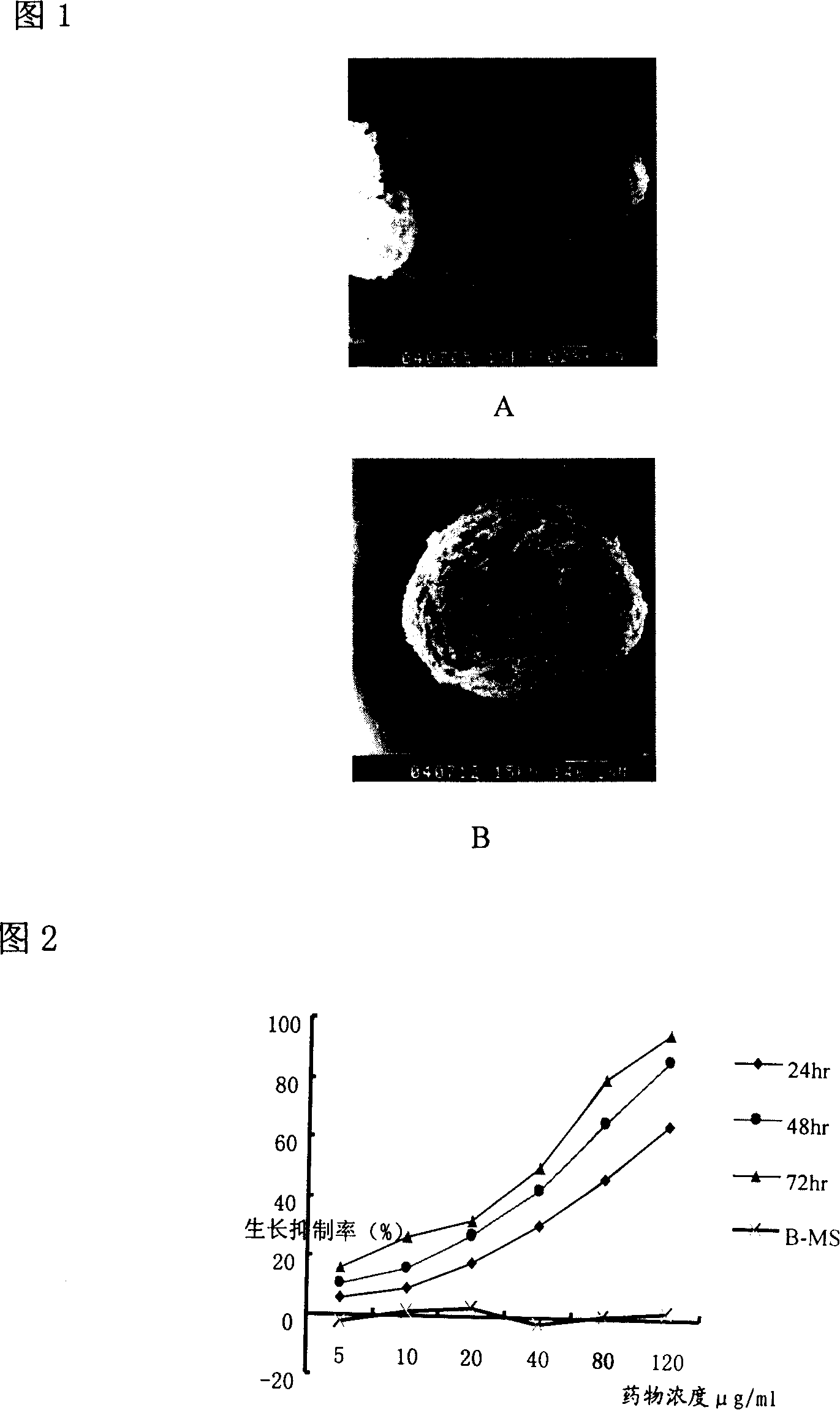

[0027] The test results of the physical and chemical properties of the microspheres show that the microspheres are uniform in size and round in shape, and the 95% confidence limit of the particle diameter of th...

Embodiment 2

[0028] Embodiment 2 Preparation process optimization of norcantharidin-alginic acid / polyanhydride microspheres

[0029] The preparation method is the same as in Example 1. According to the preliminary test results affecting particle size and material recovery rate, select the concentration of PLGA, oil phase volume, double emulsification stirring speed and four factors of stirring time, each factor selects 3 levels, and press Orthogonal Design Table L 9 (3 4 ) to conduct experiments under the set conditions to optimize the process parameters.

[0030] Table 1 is the orthogonal experiment factor and level table A2B1C3D1.

[0031] Table 2. Orthogonal Design Table L 9 (3 4 ) Experiment arrangement. .

[0032] Table 1.

[0033]

[0034] Table 2.

[0035] Test number

[0036] For the optimization method of microsphere preparation, encapsulation efficiency, particle size, in vitro drug release (including burst release effect) and material recovery were us...

Embodiment 3

[0043] Example 3 Effect of Alginic Acid and Polyanhydride Ratio on the Properties of Microspheres

[0044] Microspheres were prepared according to the ratio of alginic acid and polyanhydride in Table 5, and the method was the same as in Example 1.

[0045] Table 5. The ratio of alginic acid and polyanhydride to norcantharidin microspheres

[0046]

[0047] The results showed that; with the increase of alginic acid dosage, both drug and particle size increased. The reason for the analysis is that the increase in the amount of alginic acid increases the viscosity of the colostrum, making it difficult to form smaller complex emulsion droplets in the next step of emulsification. However, the viscosity of alginic acid increases, which obviously affects its yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com