Chain for use in automobile engine

An automobile engine, a pair of technology, applied in the direction of transmission chain, metal material coating process, coating, etc., can solve the problems of inability to exert durability, promote wear, increase maintenance burden, etc., to suppress abnormal wear extension and improve durability Excellent abrasion resistance and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Fig. 1 is a partial perspective view showing a roller chain according to an embodiment of the present invention. In this FIG. 1 , in order to clarify the internal structure of the roller chain, it is shown in a partially cutaway state.

[0044] In the roller chain 10, both ends of a sleeve 12 are respectively pressed into the sleeve holes 11a of a pair of inner plates 11, and both ends of a pin 15 loosely penetrating through the sleeve 12 are pressed into the pair of inner plates. The pin holes 14a of a pair of outer plates 14 on both outer sides of the plate 11. Furthermore, a roller 13 is rotatably inserted outside the sleeve 12 .

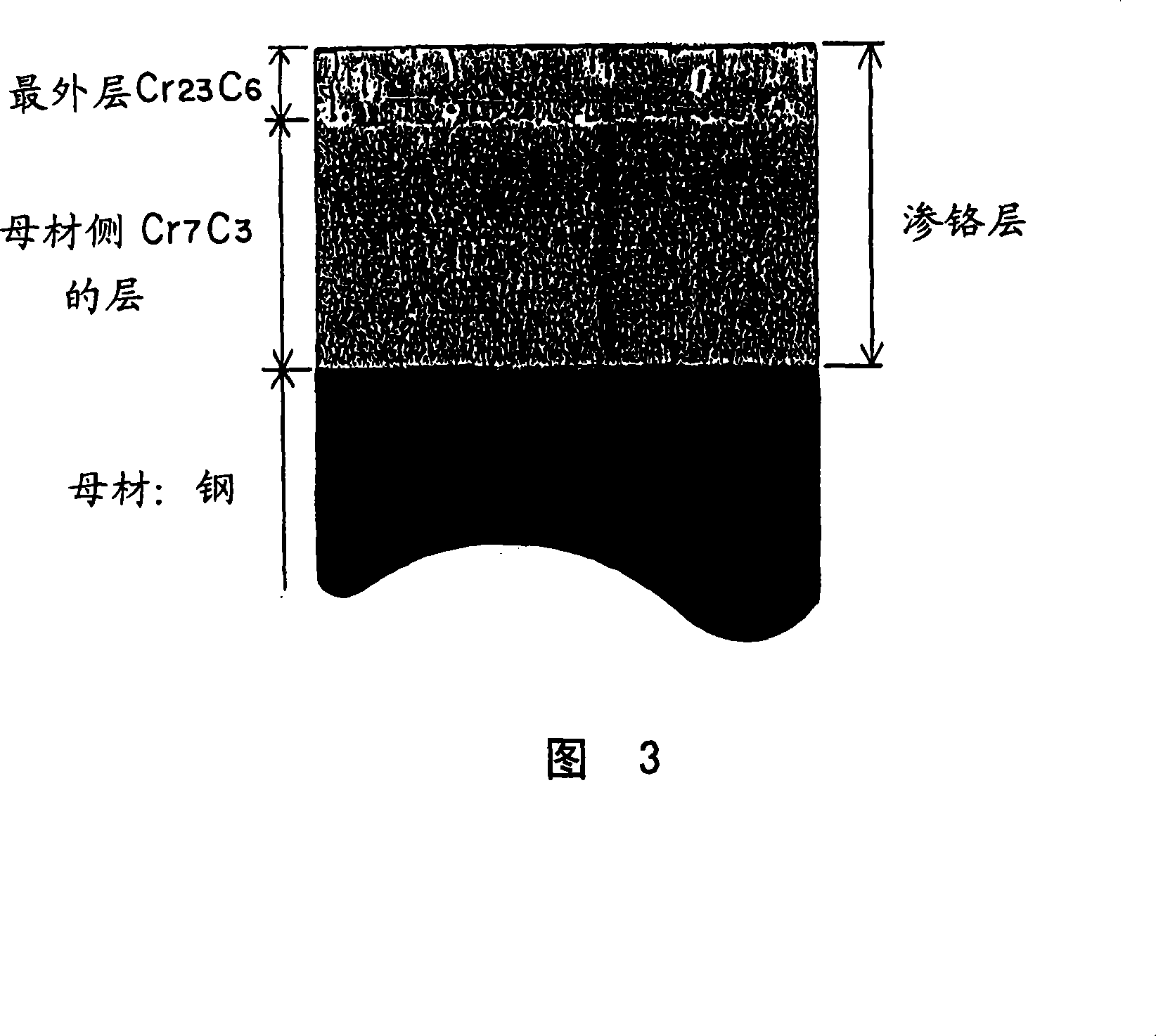

[0045] In the roller chain 10 of the present invention, the sleeve 12 is made of alloy steel, and a high-carbon surface layer is formed on the surface 15 a of steel or low-carbon steel as a base material of the pin 15 . The method of forming this high-carbon surface layer is not particularly limited, but it can be carried out by a so-cal...

Embodiment 2

[0061] Based on the automobile engine chain of Example 2, on the basis of the structure of the roller chain of Example 1, the content of Cr was reduced by using barrel grinding treatment. 23 C 6 The surface roughness of the outermost layer of pin 15, containing Cr 23 C 6 The outermost layer is porous (porous), and the exposed part of the porous part becomes a pit, where the liquid is stored and functions, so the "good lubricity" can last for a long time. The "durability" of the child chain. In order to make the surface roughness smaller in this way, by using barrel grinding, the pin as the workpiece and the abrasive rub against each other in the barrel groove, so that small parts such as pins can be efficiently ground.

[0062] From the results of the chain elongation test shown in Fig. 2, when the roller chain of Example 2, which has a smaller surface roughness, and the roller chain of the conventional example are compared after 50 hours of the test time, the chain elongat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com