Production method for high-purity arsenic and its equipment

A production method and technology of production equipment, which are applied in the production method of ultra-high-purity α-type arsenic for semiconductor basic materials and the field of special equipment thereof, can solve the problem of impurity content not meeting quality requirements, hidden dangers of production workers and environmental safety, and distillation towers. Vibration and other problems, to achieve the effect of reducing the process of synthesizing alloys and separation, solving pollution problems and safety hazards, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

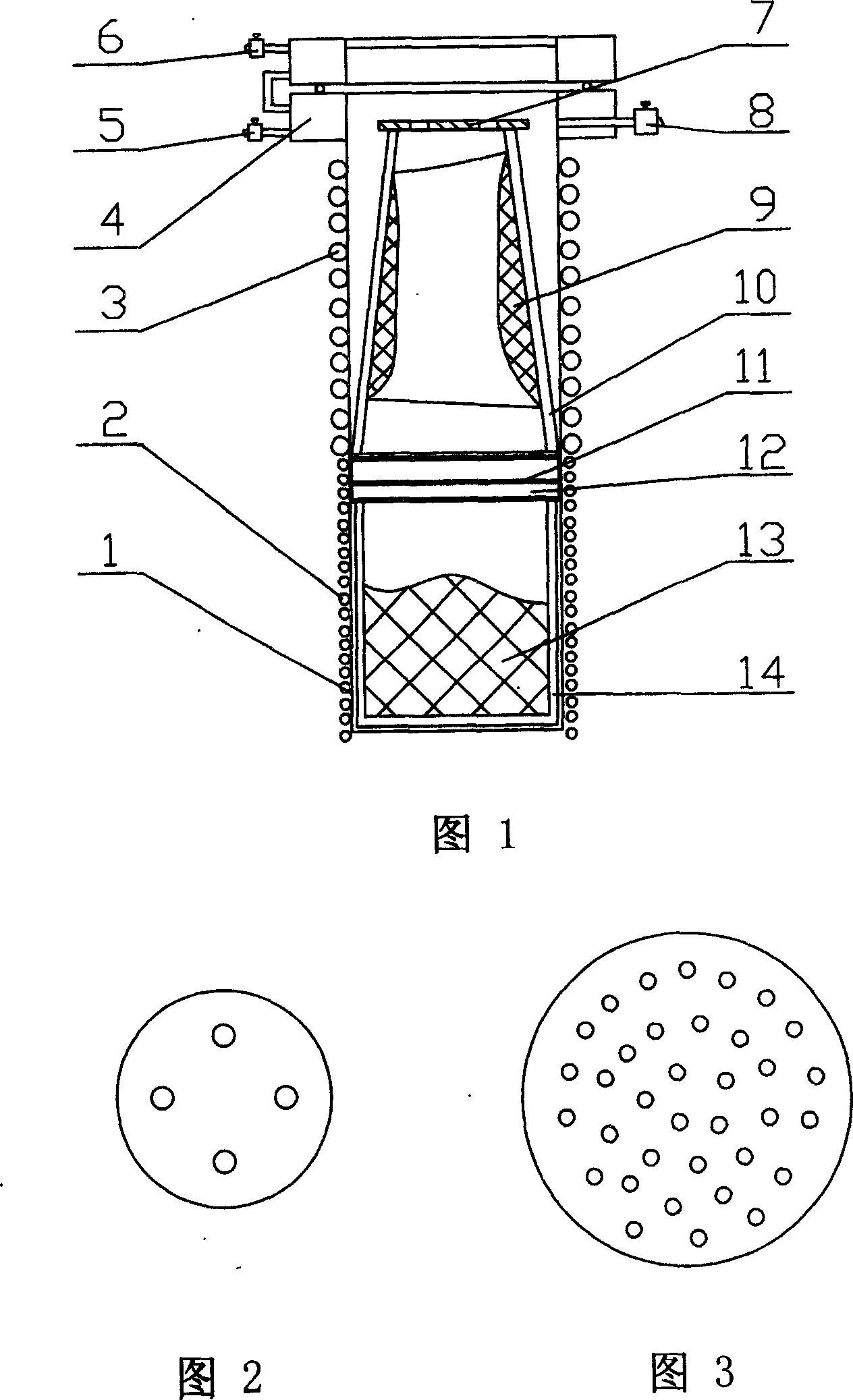

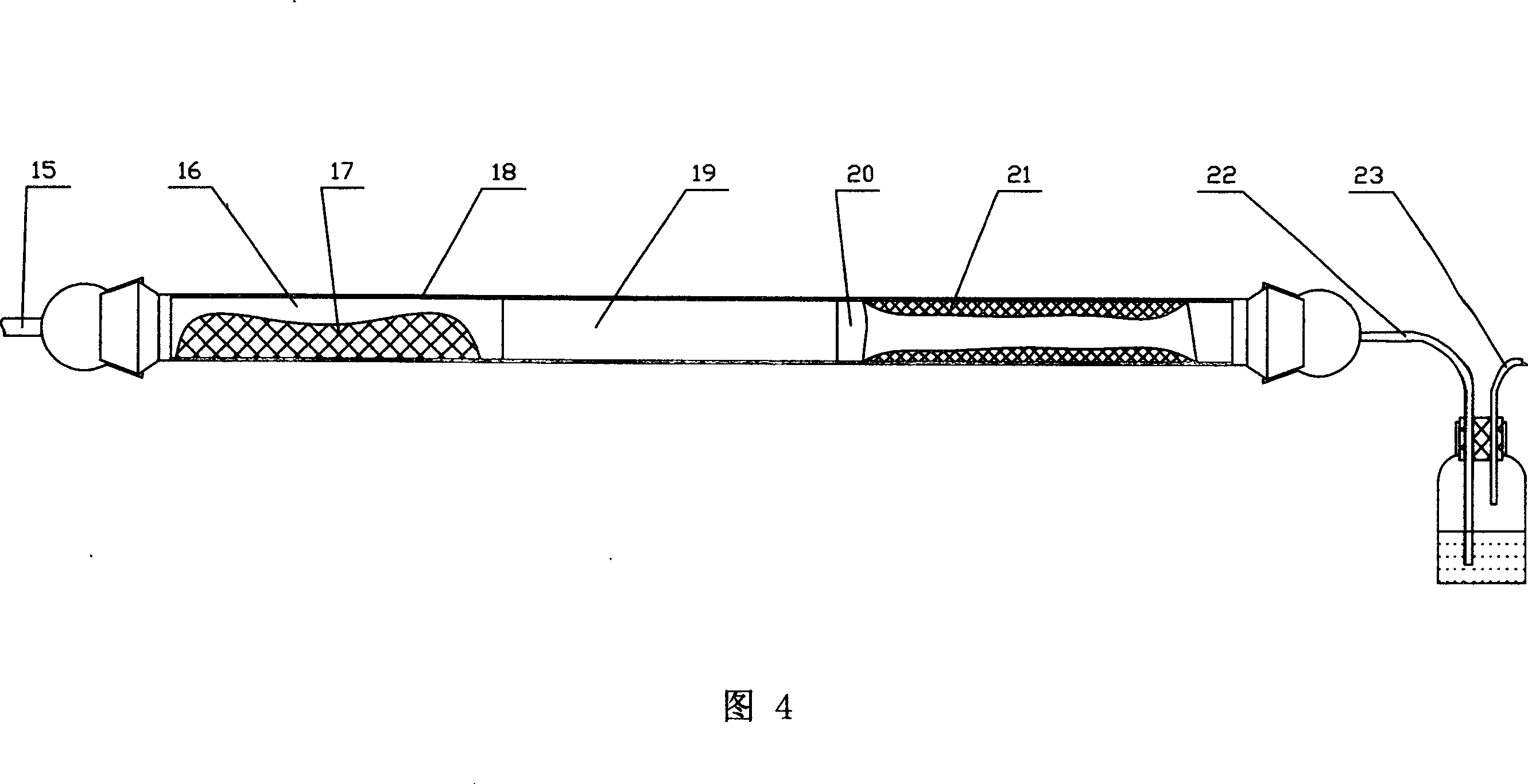

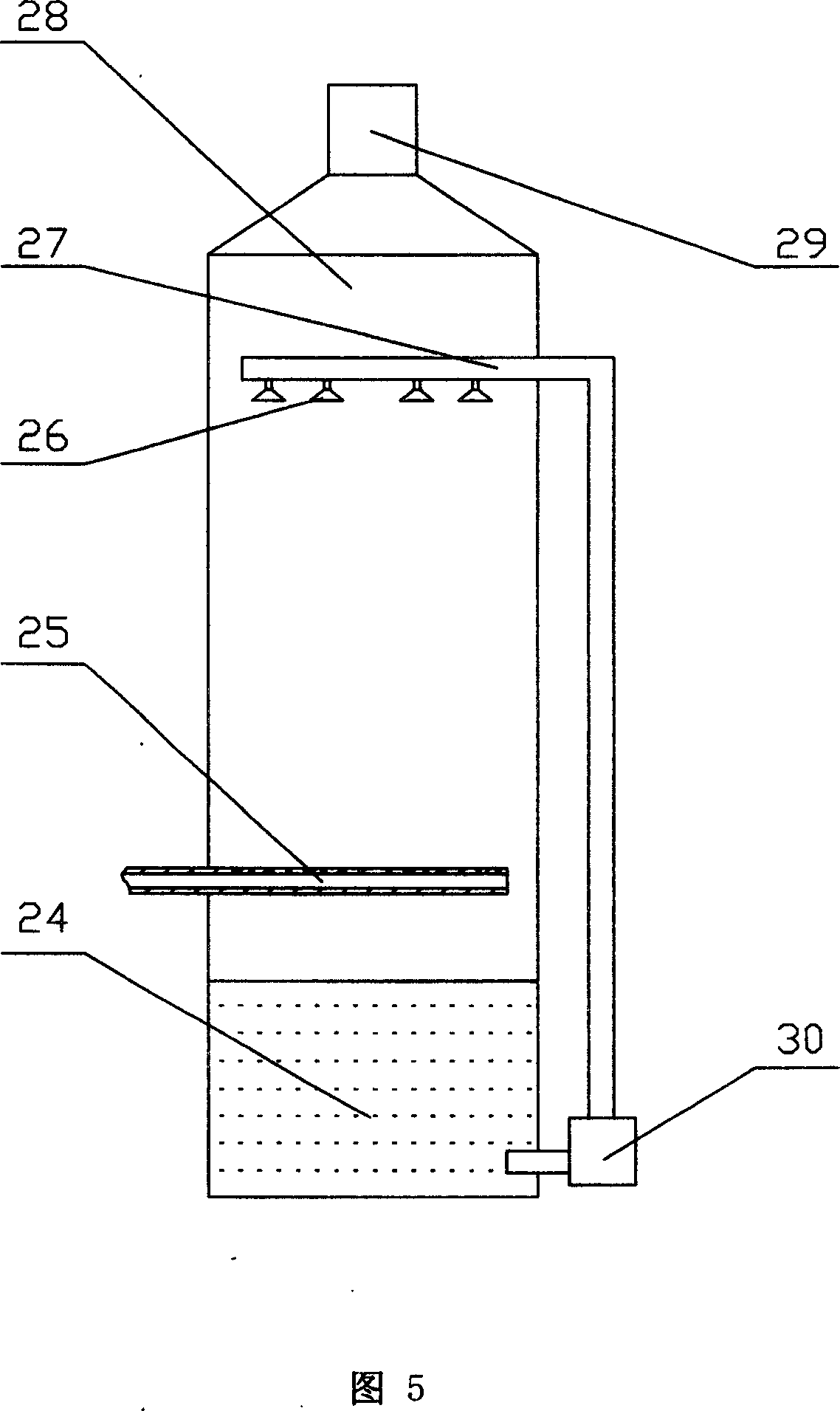

[0034] First the raw material industry 1 #Arsenic 13 (purity is 99%) is put into a crucible 14, and crucible 14 is placed in the vacuum tank 1 again, then, connect a blocker 11 with 2 layers of stainless steel thin plates at the mouth of crucible 14, on the blocker 11 Covered with small holes of Φ2mm, the interlayer of the barrier 11 can be filled with some high-temperature-resistant, pollution-free and microporous adsorption materials 12, such as activated carbon, etc., and the upper part of the barrier 11 is connected with a conical condensation cylinder 10, and the conical condensation The cylinder 10 is made of titanium, and the surface has roughness requirements. A low-boiling collecting plate 7 of matching size is arranged at the small opening of the upper end of the conical condenser cylinder 10. The low-boiling collecting plate 7 is made of metal material, and three holes of Φ30mm are arranged on the surface . The outer ring of the mouth of the vacuum tank 1 is provid...

Embodiment 2

[0040] First the raw material industry 1 # Arsenic 13 (purity is 99%) is put into a crucible 14, and crucible 14 is placed in the vacuum tank 1 again, then, connect a blocker 11 with 2 layers of stainless steel thin plates at the mouth of crucible 14, on the blocker 11 Covered with small holes of Φ3mm, the interlayer of the barrier 11 can be filled with some high-temperature-resistant, pollution-free and microporous adsorption materials 12, such as activated carbon, etc., and the upper part of the barrier 11 is connected with a conical condensation cylinder 10, and the conical condensation The cylinder 10 is made of titanium, and the surface has roughness requirements. A low-boiling collecting plate 7 of matching size is arranged at the small opening of the upper end of the conical condensing cylinder 10. The low-boiling collecting plate 7 is made of metal material, and three holes of Φ25mm are arranged on the surface. . The outer ring of the mouth of the vacuum tank 1 is pro...

Embodiment 3

[0045] First the raw material industry 1 # Arsenic 13 (purity is 99%) is put into a crucible 14, and crucible 14 is placed in the vacuum tank 1 again, then, connect a blocker 11 with 2 layers of stainless steel thin plates at the mouth of crucible 14, on the blocker 11 Covered with small holes of Φ4mm, the interlayer of the barrier 11 can be filled with some high-temperature-resistant, pollution-free and microporous adsorption materials 12, such as activated carbon, etc., and the upper part of the barrier 11 is connected to a conical condensation cylinder 10, which is conical Condenser cylinder 10 is made of titanium, and the surface has roughness requirements. A low-boiling collecting plate 7 of matching size is arranged at the small opening of the upper end of conical condensing cylinder 10. Low-boiling collecting plate 7 is made of metal material, and three Φ20mm hole. The outer ring of the mouth of the vacuum tank 1 is provided with a cooling water jacket 4, and the cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com